Countersunk Cap Routel for Spider AT14 40-46mm glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 Piece/Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

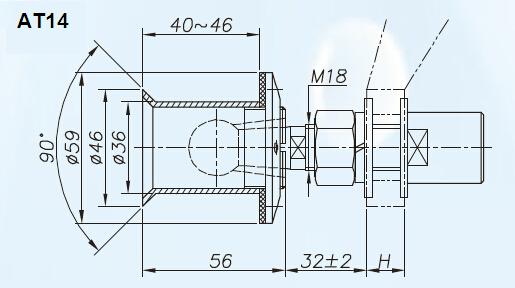

Product Name | Countersunk Cap Routel for Spider AT14 40-46mm glass |

Material | Stainless Steel 304/316. |

Finish | Natural |

Glass thickness | 40~46mm |

Bolt Size | M18 |

Max. axial bearing capacity | 6500N |

Max. Radial Bearing capacity | 2800N |

Adjustable angle | ±10 degree |

Min Order | 100piece/ pieces |

Packing | Inner Box + Carton Box |

Supply capacity | 100000 piece/ pieces per month |

Delivery time | 20~35 days after receipt of down payment |

Export market | Asia, America, Europe, Africa, markets. |

1. Reliable Supplier |

2. High Quality |

3. Standard Producing Technology |

4. Competitive Factory Price |

5. Fast Delivery |

Product Pictures:

- Q: Curtain wall claw claw how much appropriate? How much is a square? Please professional answer, plus points plus points

- See you how thick the glass!

- Q: Curtain wall materials, hardware accessories which

- Chemical anchor bolt, core pulling rivets, self-tapping screws, even the claws, angle aluminum (code) and so on.

- Q: What are the specifications of the curtain wall?

- Common specifications for curtain wall claws: Material: 201,304,316; Size: 200,220,250,300;

- Q: Do you want to glue when you install a splice?

- Are mechanically connected by bolts.

- Q: What are the specifications of the curtain wall

- 220 series, 250 series, generally use these two series more.

- Q: The production of curtain wall glass splicing claws of the big brand which several!

- I heard a friend introduced a good with a good, so very good, the price can be, the quality did not say that after all, is a strong sub-brand. Hope to help you.

- Q: The kind of glass that is attached to the pawl, I would like to ask how the size of the glass is accurate? Starting from that point?

- This is very annoying I basically is in the CAD on the painting, more intuitive, just split the middle of the base of the claw (the size is the size of the glass is not buckle), look at the claw claw series (220 series is to Medium size minus 110) and then deduct half a seam, is the hole size. The size of the glass is medium to medium size minus a rubber seam size, rectangular, then so. Irregular shape also need the amount of diagonal. If not the middle of the glass is the edge of the glass is the same way, put their own in the CAD like to know! search for If you want to be accurate point, then do not install the base so that workers in the steel legs on the ball line and then you can cross the line. The intersection of the intersection line is the center of your base.

- Q: I want to open a stainless steel products Monopoly, do not know what stainless steel? Which companies need stainless steel? Which industries need stainless steel?

- Stainless steel products: stainless steel glass railings, handrails, stainless steel glass partitions, stainless steel curtain wall adapter, splice joints, splicing claws, glass clip, handrail fittings, canopy accessories, support rods, rods, cable, stainless steel mini Stainless steel flower bucket, trash cans, fire protection boxes, telephone booths, check counters, telescopic mobile railings, long and gradually fine flagpoles, multi-purpose air conditioning, Metal seats, luggage carts and other products.

- Q: How many of the glass curtain wall are to be welded to the pillar

- Specific force situation Caixing, Rui Teng curtain wall is the industry well-known brands, you can ask their technical staff.

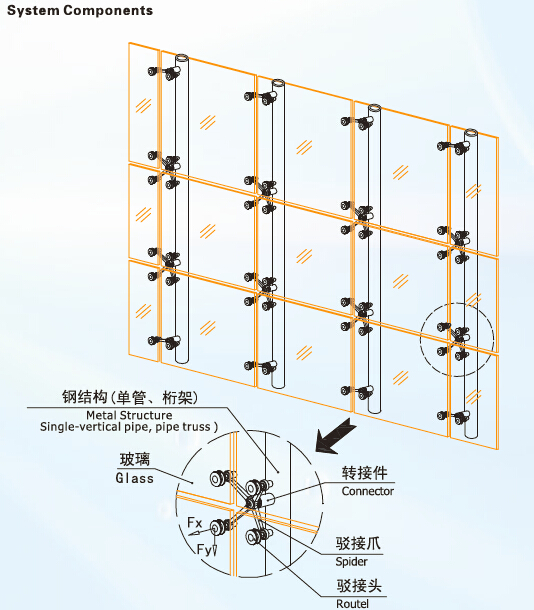

- Q: Curtain wall panel installation control points which

- The splicing jaws serve as an important accessory to the glass curtain wall, which plays an important role in the connection of the glass curtain wall. The mechanical properties are particularly important by passing the load to the steel structure or other body structure through the splice joint. Of the installation staff, in the point of the installation of the curtain wall accessories need to master more technical and knowledge points. Introduction is the stainless steel splicing jaws when you need to pay attention to the installation of some of the details, hoping to help everyone. The stainless steel splicing pawl-type curtain wall fittings are composed of splice joints, splicing claws, adapter parts and so on. The splicing jaws are mainly used as supporting link joints and pass the load to the fixed supporting structure system, which is connected with the glass curtain wall An important accessory. With the impact of the curtain wall industry, in order to achieve the best effect of the use of stainless steel splicing claws, construction details are essential, and today to introduce some of the details of the construction of the splicing claws and the need to pay attention to the problem. The first is the preparation before the installation.

Send your message to us

Countersunk Cap Routel for Spider AT14 40-46mm glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 Piece/Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches