The Square Glass Clamp for Fix Lass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Pieces pc

- Supply Capability:

- 1200 Pieces Per Day pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

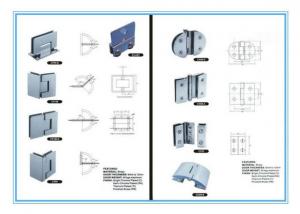

Detailed Product Description of The Square Glass Clamp For Fix The Lass

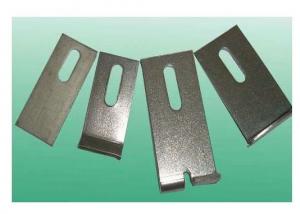

1,Material: Stainless Steel

2,Usage: Glass Clamp forbuilding

3,Standard or Nonstandard: Standard

4,size and thickness:custom

1. Main specifications of Glass clamps

Process | Lost wax casting(Silica method) |

Key specification |

1.Material: stainless steel 304 316 316L

2.Standard: ASTM\DIN\BS\JIS

3.Surface finish: stain polished or mirror polished

4.Weight: about 200-300grams

5.Useful: 8-20mm width glass |

production facility | 1.Casting facility: wax injector, paint mixer, medium-frequency induction furnace, box resistance furnace, cutting head machine, shot-blasting machine, sand-blasting machine, pickling line. 2.Machining facility: CNC machine, linear cutting machine, NC milling machine, polishing machine. |

Heat treatment | Solid solution. |

Testing facility | spectrometer, tensile test machine, hardness test machine, mircoscope. |

2.About Products:

(1)We can produce your goods according to your drawings, also can do complicated products.

(2)We can do CNC machining and many kinds surface treatment, just tell me your requirements on physical properties.

3. About quality of The Square Glass Clamp For Fix The Lass

1)Our products are tested by spectrometer before pouring, so just forget the material requirements.

2)Our spectrometer is introduced from Germany in 2007.

3)Our workers test each piece before store it.

4.About Factory

(1)Experience:We have 16 years experience in casting and take the lead in passing ISO9001:2000 among the same industry.

(2)Good After Sales Service:We have advanced facilities to guarantee our product's quality and any small problem happening of our products will be solved at the most prompt time.

5.Our market:

Popular in the Europe and America, also in Janpan and South Korea.

- Q: Clip glass with a handrail pieces of how much money, large amount of where the wholesale right

- Fence on the commonly used type of split pieces are generally 120mm and 160mm

- Q: What is the difference between a curtain wall countersunk connector and a floating head connector?

- Floating head spliced part of the exposed outside the panel, countersunk head is embedded in the middle of the panel.

- Q: How many errors can be made by welding the splicing jaws

- To be reasonable at the beginning of the adapter and the steel frame between the contacts designed, I make a simple example: Now there are a lot of steel frame is welded with a round tube, that adapter The base in the production of the time also need to be cut into the arc, so that steel pipe can be better connected to the tube, while reducing the interface of the degree of restraint, and secondly, reasonable arrangement of welding order to reduce the welding stress, Welding at the same time can reduce the heat generated when welding cracks. Welding starting point and the mouth is easy to produce cracks, conditional welding joints should be at the plus arc plate and arc plate. If you can not use the arc plate, the best use of attenuation current arc, and fill the crater. At the same time in the welding process in order to reduce the weld cracks, as far as possible the use of small lines of energy and cross-section of the welding point. If the process of welding found in the leak, if not serious, then gently knock with a hammer may be just fine. To avoid this is best to the workers carefully, in the welding when the cautious point of these problems can be avoided.

- Q: What is the point of the ribbed curtain wall

- Point refers to the point of the type, the glass panel is fixed by the stainless steel dial system; rib dial refers to the dial system is fixed in the rear of the panel on the floor. The most common is the glass ribs point of the curtain wall.

- Q: Members of the master is good, I want to pull the claw side of the stainless steel support the side of the glass, one side installed in the antiseptic wood, please practice in the anti-wood that side how to install, how fixed on the wood preservative.

- Directly with expansion bolts fixed on the wood preservative. The splicing jaws are mainly used as support joints and transfer loads to a fixed support structure, which is an important accessory to the glass curtain wall.

- Q: What is the splice

- The splice is a glass curtain wall fitting, used in combination with a split pawl, with a 4-jaw claw with 4 splice joints.

- Q: What is the reason for rusting the claws?

- 1, the surface of stainless steel deposits with other metal elements of dust or heterogeneous metal particles attached to the wet air, between the attachment and stainless steel condensate, the two together into a micro-battery, triggering the electrochemical reaction , The protective film is damaged, called electrochemical corrosion. 2, stainless steel surface adhesion of organic juice (such as melon vegetables, soup soup sputum, etc.), in the case of water and oxygen, constitute organic acids, long time to form organic acid corrosion of metal surface. 3, stainless steel surface adhesion containing acid, alkali, salt substances (such as decorative walls of alkaline water, lime water spray test) caused by local corrosion. 4, in the contaminated air (containing a lot of sulfide, oxide, hydrogen oxide atmosphere), in case of condensate, The formation of sulfuric acid, nitric acid, acetic acid liquid point, causing chemical corrosion. The above can cause damage to the surface of the stainless steel protective film, causing corrosion. So, to ensure that the metal surface is permanently bright and not rusty, we recommend: ① must always clean the surface of the decorative stainless steel scrub, remove the attachment, to eliminate the external factors that cause corrosion. ② There is a 201 and 202 stainless steel in the market is easy to rust in the coastal area, suitable for use in industrial pollution and air corrosion environment. ③ beach area to use 304 stainless steel, 304 material can resist seawater corrosion.

- Q: How to distinguish between the claw is 220 series or 250 series

- You can measure the distance between the center of the adjacent joints, the industry is generally the default hole pitch model. 220 series represents the adjacent hole center distance is 220mm.

- Q: How many of the glass curtain wall are to be welded to the pillar

- Specific force situation Caixing, Rui Teng curtain wall is the industry well-known brands, you can ask their technical staff.

- Q: Curtain wall decoration line junction how to take a good connection

- AFA Binders are architectural adhesives for unique formulations of OKorder Eau De Toilette Decoration Engineering Co., Ltd. (formerly Alfa Wall Decoration Engineering Co., Ltd.).

1. Manufacturer Overview

| Location | Shanghai,China |

| Year Established | 2003 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Western Europe Northern Europe |

| Company Certifications | IS09001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 11% - 20% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | Below 1,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | |

Send your message to us

The Square Glass Clamp for Fix Lass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Pieces pc

- Supply Capability:

- 1200 Pieces Per Day pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords