Countersunk Cap Routel for Spider AT43

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 Piece/Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

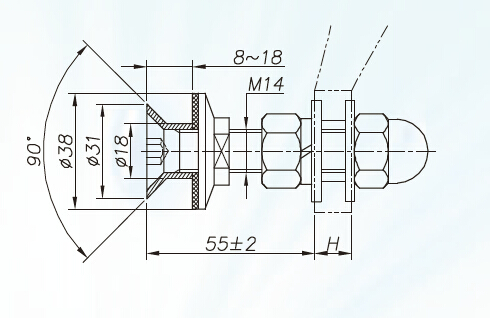

Product Name | Countersunk Cap Routel for Spider AT43 |

Material | Stainless Steel 304/316. |

Finish | Natural |

Glass thickness | 8~18mm |

Bolt Size | M14 |

Max. axial bearing capacity | 4500N |

Max. Radial Bearing capacity | 2000N |

Adjustable angle | ±10 degree |

Min Order | 100piece/ pieces |

Packing | Inner Box + Carton Box |

Supply capacity | 100000 piece/ pieces per month |

Delivery time | 20~35 days after receipt of down payment |

Export market | Asia, America, Europe, Africa, markets. |

1. Reliable Supplier |

2. High Quality |

3. Standard Producing Technology |

4. Competitive Factory Price |

5. Fast Delivery |

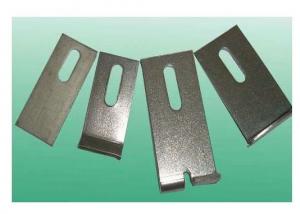

Product Pictures:

Countersunk Cap Routel for Spider AT43

- Q: Who knows which factory is good? Recommended!

- Not bad money to buy hard, the best brand.

- Q: Tempered glass shed with 22o of the split jaws, how to calculate the location of the glass hole ah

- Usually between the glass to stay 10mm glue, two pieces of glass split hole center spacing 220mm, hole to the glass edge of the distance: (220-10) / 2 = 105 mm

- Q: What are the specifications of the curtain wall

- 220 series, 250 series, generally use these two series more.

- Q: What are the metal members connecting the glass and the glass ribs in the glass curtain wall?

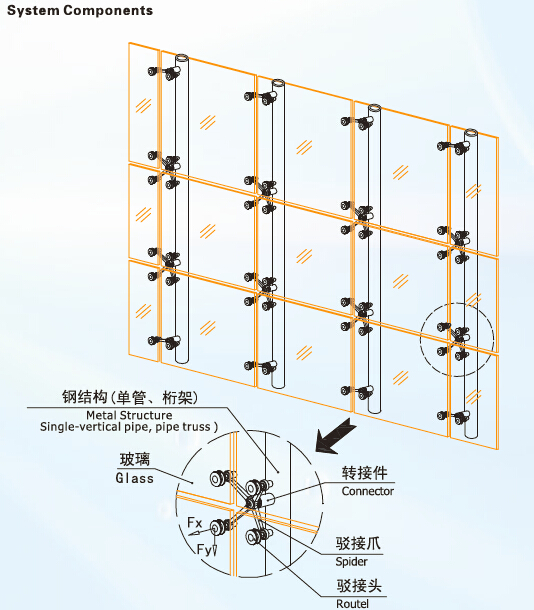

- The point-type glass curtain wall is composed of splicing joints, splicing claws, adapters and other components, the main claw claw as a support link, and the role of the load to the fixed support structure, is connected to the glass curtain wall is an important accessories The

- Q: What are the accessories of the point-supported glass curtain wall?

- Mainly to connect joints, splicing claws, adapter, fixture, support rod, cable, rod, etc., what difficulties can say ah, I can help you solve the initial ah

- Q: What is a round steel nail on a glass curtain wall?

- You say is the point of the glass curtain wall of the steel claws, you see the circular nails are steel claws through the glass after the floating head or countersunk head

- Q: What is the splice

- The spliced connector is a fitting for a glass curtain.

- Q: 250 type curtain wall glass connection pawls how much punch

- Directly check the type of 250-type point curtain wall joints, see the size of the joints to know.

- Q: Curtain wall decoration line junction how to take a good connection

- AFA Binders are architectural adhesives for unique formulations of OKorder Eau De Toilette Decoration Engineering Co., Ltd. (formerly Alfa Wall Decoration Engineering Co., Ltd.).

- Q: Curtain wall panel installation control points which

- The splicing jaws serve as an important accessory to the glass curtain wall, which plays an important role in the connection of the glass curtain wall. The mechanical properties are particularly important by passing the load to the steel structure or other body structure through the splice joint. Of the installation staff, in the point of the installation of the curtain wall accessories need to master more technical and knowledge points. Introduction is the stainless steel splicing jaws when you need to pay attention to the installation of some of the details, hoping to help everyone. The stainless steel splicing pawl-type curtain wall fittings are composed of splice joints, splicing claws, adapter parts and so on. The splicing jaws are mainly used as supporting link joints and pass the load to the fixed supporting structure system, which is connected with the glass curtain wall An important accessory. With the impact of the curtain wall industry, in order to achieve the best effect of the use of stainless steel splicing claws, construction details are essential, and today to introduce some of the details of the construction of the splicing claws and the need to pay attention to the problem. The first is the preparation before the installation.

Send your message to us

Countersunk Cap Routel for Spider AT43

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 Piece/Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords