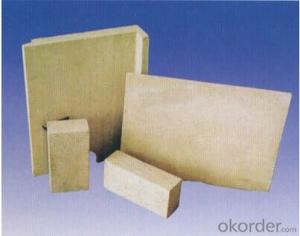

Cordierite-mullite Refractory Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Cordierite-mullite brick

1. low thermal expansion coefficient,

2. excellent stability of thermal shocking

| Alumina-Silica Refractory Series Products | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cordierite-mullite brick is of low thermal expansion coefficient, excellent stability of thermal shocking, it is used in assembly brick for hot blast stove. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Physical and chemical index :

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

- Q: Do insulating fire bricks have low thermal conductivity?

- Yes, insulating fire bricks have low thermal conductivity.

- Q: Can insulating fire bricks be used in boilers for residential heating?

- Yes, insulating fire bricks can be used in boilers for residential heating. Insulating fire bricks are designed to withstand high temperatures and provide effective insulation, making them suitable for use in boilers to improve energy efficiency and heat retention.

- Q: Can insulating fire bricks be used for insulation in chemical reactors?

- Insulation in chemical reactors can be achieved by utilizing insulating fire bricks. These bricks, made from lightweight materials like vermiculite or perlite, possess exceptional thermal insulation properties. They are specifically designed to endure high temperatures and can be applied in various scenarios, including chemical reactors. Chemical reactors often operate at heightened temperatures, making it crucial to maintain a stable temperature for efficient and safe functioning. By employing insulating fire bricks as insulation in chemical reactors, the loss of heat can be minimized, resulting in increased energy efficiency and cost savings. Furthermore, these bricks aid in reducing temperature variations within the reactor, ensuring even distribution of heat and enhancing overall performance. Moreover, insulating fire bricks exhibit resistance to chemical deterioration, enabling them to withstand the corrosive impact of different chemicals employed in chemical reactions. This quality makes them suitable for usage in chemical reactors frequently exposed to corrosive substances. To summarize, insulating fire bricks offer an exceptional choice for insulation in chemical reactors. They provide outstanding thermal insulation, endure high temperatures, and possess resistance to chemical attack. By utilizing insulating fire bricks in chemical reactors, improved energy efficiency, temperature stability, and overall reactor performance can be achieved.

- Q: Can insulating fire bricks be used for insulation in glass manufacturing?

- Yes, insulating fire bricks can be used for insulation in glass manufacturing. Insulating fire bricks offer high-temperature resistance and low thermal conductivity, making them suitable for insulation and maintaining consistent temperatures during glass manufacturing processes.

- Q: Are insulating fire bricks resistant to alkali attack?

- Insulating fire bricks generally possess resistance to alkali attack. They are composed of high-temperature refractory materials and are engineered to endure extreme temperatures and chemical surroundings. Alkalis typically corrode and deteriorate certain substances, but insulating fire bricks are specifically devised to withstand this form of chemical assault. They possess limited porosity and a compact structure, thereby thwarting alkalis from infiltrating the brick's surface. Furthermore, the refractory materials employed in these bricks possess a high melting point and exhibit chemical inertness, rendering them ideal for situations where exposure to alkali is a concern. However, it is crucial to acknowledge that the resistance of insulating fire bricks to alkali attack may vary depending on the brick's composition, manufacturing process, as well as the concentration and duration of alkali exposure. Thus, it is always advisable to consult the manufacturer or supplier for comprehensive details regarding the alkali resistance of their specific insulating fire bricks.

- Q: Can insulating fire bricks be used in contact with molten metal?

- Indeed, it is possible to utilize insulating fire bricks in direct contact with molten metal. Specifically engineered to endure extreme temperatures, these bricks are widely employed in industrial settings where they encounter molten metal. With their exceptional resistance to thermal shock, they are capable of withstanding the intense heat generated by molten metal. Furthermore, insulating fire bricks possess low thermal conductivity, thereby reducing heat loss and enhancing energy efficiency. However, it is crucial to ascertain that the specific variant of insulating fire brick employed is suitable for the specific type of molten metal and temperature range it will be exposed to. Different metals possess varying melting points, which may necessitate the use of more specialized refractory materials.

- Q: Insulation brick should pay attention to external walls?

- In each segment or block the tiles are from bottom to top paste, from the line of position the next layer of hypodermis first brick hidden good ruler, to hold the first leather tiles, pull in tile lines as the upper skin paste standard.

- Q: Are insulating fire bricks resistant to reducing atmospheres?

- Yes, insulating fire bricks are resistant to reducing atmospheres. These bricks are specifically designed to withstand high temperatures and harsh conditions, including exposure to reducing atmospheres. They are made from high-quality refractory materials that are capable of resisting the effects of reducing atmospheres, which can contain gases such as carbon monoxide or hydrogen. Insulating fire bricks have a low thermal conductivity and high insulating properties, making them ideal for applications where reducing atmospheres are present. They can effectively protect the surrounding areas from heat transfer and prevent damage to the structure. Additionally, these bricks have a high mechanical strength and excellent resistance to thermal shock, allowing them to maintain their integrity even in challenging conditions. In summary, insulating fire bricks are indeed resistant to reducing atmospheres due to their durable construction and ability to withstand high temperatures and harsh environments.

- Q: Can insulating fire bricks be used for insulation in ovens and kilns?

- Yes, insulating fire bricks can be used for insulation in ovens and kilns. Insulating fire bricks are specifically designed to withstand high temperatures and provide excellent thermal insulation. They are made from lightweight materials like clay and other refractory materials that have low thermal conductivity. This means that they can effectively retain heat and prevent it from escaping, making them ideal for use in ovens and kilns where heat retention is crucial. Additionally, insulating fire bricks are resistant to thermal shock, meaning they can withstand rapid changes in temperature without cracking or breaking. Overall, insulating fire bricks are a reliable choice for insulating ovens and kilns, ensuring efficient heat distribution and energy conservation.

- Q: Can insulating fire bricks be used in the construction of cremation chambers?

- Insulating fire bricks have the capability to be utilized in the construction of cremation chambers. These bricks are manufactured using lightweight materials such as vermiculite or perlite, which possess remarkable insulating properties. These properties render them suitable for high-temperature applications like cremation chambers, where they are instrumental in maintaining a consistent and controlled temperature. The utilization of insulating fire bricks in the construction of cremation chambers yields numerous benefits. Firstly, these bricks aid in enhancing energy efficiency by minimizing heat loss. This subsequently leads to reduced fuel consumption and cost savings. Secondly, the insulating properties of these bricks ensure that a stable temperature is maintained within the cremation chamber, which is crucial for achieving efficient and complete combustion of the deceased. Furthermore, these bricks are lightweight and easy to handle, thereby facilitating a more convenient and efficient construction process. Nevertheless, it is worth noting that although insulating fire bricks can be employed in the construction of cremation chambers, they are typically used in conjunction with refractory fire bricks. Refractory fire bricks are fabricated from materials such as clay or silica, which possess the ability to withstand exceedingly high temperatures. These bricks are installed in areas of the cremation chamber that come into direct contact with the flames, while insulating fire bricks are utilized in areas that require insulation. In conclusion, insulating fire bricks are a suitable choice for the construction of cremation chambers due to their excellent thermal insulation properties and ability to contribute to the efficient and controlled operation of the cremation process.

Send your message to us

Cordierite-mullite Refractory Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords