Copper Mine Grinding Ball with High Hardness, Low Price and Top Quality

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

As one of the leading grinding balls specialists in China, we can certainly assist you in buying grinding balls that suit your company needs. Our annual production capacity is about 50000MT. We own an integrated set of advanced import production line, so that you can be satisfied with the quality of our products.

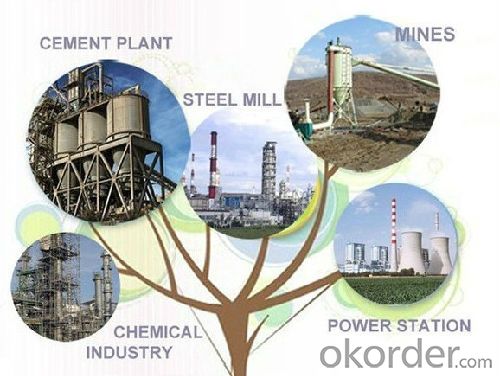

Applied Fields of Copper Mine Grinding Ball with High Hardness, Low Price and Top Quality

1. Mines

2. Cement Plants

3. Chemical Industries

4. Power Stations

Packaging of Copper Mine Grinding Ball with High Hardness, Low Price and Top Quality

Ton bags (1000Kg Per Bag)

Iron drums (850~920Kg Per Drum)

Chemical Composition of Copper Mine Grinding Ball with High Hardness, Low Price and Top Quality

Item | C | Cr | Si | Mn | S | P | Cu | Mo | Ni | Hardness |

Element | 0.6-1.2% | ≤ 1.0 | 0.15-0.6 | 0.6-1.5 | ≤ 0.04 | ≤0.04 | ≤0.1 | ≤0.25 | ≤0.1 | 55-65 |

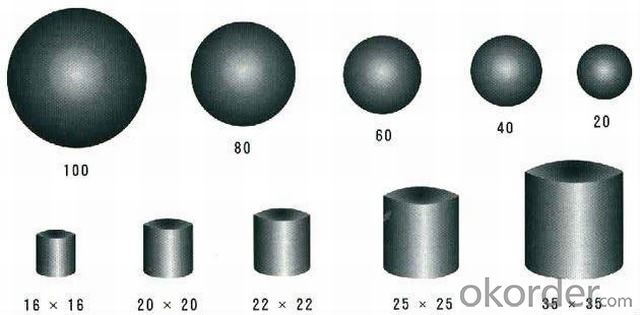

Specification and Hardness of Copper Mine Grinding Ball with High Hardness, Low Price and Top Quality

Nominal diameter (mm) | Diameteical tolerance (mm) | Weight of Single of forging ball in average | Number of piece of One ton forging ball in average | Surface hardness | Impact toughness |

DIA 20 DIA 25 DIA 30 DIA 40 DIA 50 |

+2 -1 | 32 64 110 263 513 | 31250 15625 9090 3802 1949 |

55-65 |

≥12 |

DIA 60 DIA 70 DIA 80 DIA 90 DIA 100 |

+3 -2 | 888 1410 2104 2996 4110

| 1126 709 475 333 243 | ||

DIA 110 DIA 120 DIA 130 | +4 -2 | 5457 7102 9030 | 182 140 110 | ||

DIA 140 DIA 150 | +4 -3 | 11278 13871 | 88 72 |

Application Range of Copper Mine Grinding Ball with High Hardness, Low Price and Top Quality

- Q: Casting blank in the cooling process to release a large amount of heat energy, what can be recycled?

- Casting, do not need to provide a rough casting foundry drawings, according to your chart will put foot margin in the processing needs of the surface, the rest of the size can be found according to the mechanical design manual and manual casting. General Casting Factory Casting Division will be in your chart marked on shrinkage and processing margin figure (usually with red and green pen) to the patternmaker production of wood or other material mould diagram.

- Q: How to improve the surface roughness of casting parts?

- First, the accuracy of the model should be improved; two is to change the molding technique; the three is the coating; and the worker's technical level.

- Q: Why do cheap cars like stamping parts instead of casting parts?

- We usually say that the stamping is usually refers to the cold stamping parts, for example, a piece of iron, wants to turn it into a fast food dish, it must design a set of mold, mold is working face plate shape, the pressure plate mold, it becomes you want the dishes, this is the cold stamping die stamping is the direct use of metal materials.Automobile stamping parts are mainly classified according to process, and can be divided into two major parts: separation process and forming process.

- Q: Is the cast steel a casting part?

- Cast steel is divided according to material, as well as cast iron parts, cast aluminum parts and so onCasting parts are divided according to the method, as well as forging partsCast steel parts must be casting parts

- Q: What is the difference between forging parts and casting parts?

- No, it's called die castingDifference: the die casting parts are simple in structure and large in batch sizeCasting: the use of a wide range of structures without restrictions

- Q: What's the density of the cast iron? The density is thin and the density is thin

- There is a hot knot in the thick area, which easily causes microscopic shrinkage and makes the casting not dense. A riser may be added for shrinkage relief.

- Q: Does anyone know how to make precise casting parts for aerospace or manufacturers of single and small quantities of automotive parts and components, mainly in Beijing, Tianjin and Tangshan?

- List of China's military enterprises list of ten major military groupsChina Nuclear Industry Construction Group CorporationChina Aerospace Science and Technology CorporationChina Aerospace Science and Engineering CorporationChina Aviation Industry CorporationChina Aviation Industry Corporation IiChina State Shipbuilding CorporationcsicChina North Industries Group CorporationChina South Industries Group CorporationChina National Nuclear CorporationKey military enterprisesShipbuilding industry:China State Shipbuilding Corporation (South ship group), (China Shipping Group)China Shipbuilding Industry Corp (North Ship group), (China Shipbuilding Industry)Guangzhou Shipyard International Limited by Share Ltd (GSI)Jiangnan Heavy Industry Limited by Share Ltd (Jiangnan Heavy Industry)Nuclear industry:China National Nuclear Corporation (CNNC)China Nuclear Industry Construction Group Corporation

- Q: As shown, how do I achieve the tightness test of this product, and achieve industrial production? Seek expert advice.

- Precise and tight sealing of the surface to which the test piece is to be tested, equipped with an airtight test instrument, and an electrical control system. You can complete automated testing equipment

- Q: In the design of casting steps and precautions, for casting design, we have what experience?.

- Two: the basic structure unit in the design of metal casting type and the parameters selected, usually should also pay attention to: (1) because of the metal type heat quickly, so the metal type casting minimum wall thickness should be bigger than the sand casting, metal type casting alloy minimum wall, different size of castings see table 1.1-31 thick can be selected; (2) the inner wall of the casting internal ribs and the thickness of wall thickness should be 0.6-0.7 connected, or as the inner wall (rib) cold slowly, cracks in the wall at the junction in the casting shrinkage;

- Q: How can the casting be free of trachoma?

- Measures for the prevention of trachoma in castings:1, sand compaction to high, paint two times;

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1971 |

| Annual Output Value | US$50 Million - US$100 Million |

| Main Markets | Domestic Market, Southeast Asia, South Asia, North America, South America |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese, Korean |

| b) Factory Information | |

| Factory Size: | Above 60,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Forged Grinding Ball,Cast Grinding Ball,Casting Cylpebs,Grinding Rods,Decorative Steel Ball |

| Product Price Range | Average |

Send your message to us

Copper Mine Grinding Ball with High Hardness, Low Price and Top Quality

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords