Grinding Media Ball with High Performance & Competitive Price Used for Metal Mine/Cement Plant/Water Coal Slurry/Power Station/C

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Grinding Media Ball with High Performance & Competitive Price Used for Metal Mine/Cement Plant/Water Coal Slurry/Power Station/Chemical Industry

1. Specifications for Grinding Media Ball with High Performance & Competitive Price

Diameter: 15mm-150mm

Hardness: 55HRC-65HRC

Features: a) Even Hardness b)No Deformation c) Low breaking d) No Mal-roundness F)Grinding resistant G) Low wear rate

Applied Fields: a) Metal Mines b) Cement plants c) Water coal slurry d) Power stations e) Chemical industry

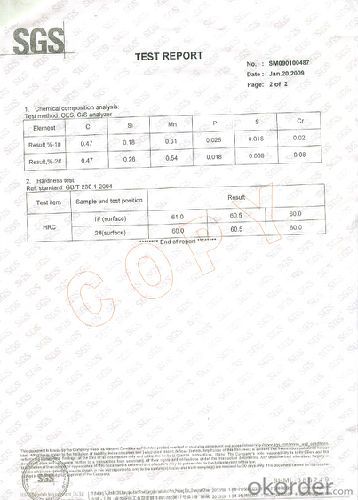

Certification: ISO9001:2008, SGS, etc

2. Classification for Grinding Media Ball with High Performance & Competitive Price

Forged Grinding Ball

Chemical Composition and Specifications of Forged Steel Grinding Ball:

Name | C | Mn | Si | Cr | S | P | ||

60Mn | 0.57-0.65 | 0.70-1.0 | 0.17-0.37 | 0.25max | 0.035max | 0.035max | ||

65Mn | 0.60-0.70 | 0.90-1.2 | 0.17-0.37 | 0.25max | 0.035max | 0.035max | ||

75MnCr | 0.70-0.85 | 0.70-0.85 | 0.17-0.37 | 0.40-0.60 | 0.030max | 0.030max | ||

| | ||||||||

Nominal diameter | Diameteical Tolerance | Weight of single ball in average | Surface hardness | Impact toughness | ||||

(mm) | (mm) | (g) | (HRC) | (j/cm2 ) | ||||

Φ20 | +2 -1 | 32 |

55-65 |

≥12 | ||||

Φ25 | 64 | |||||||

Φ30 | 110 | |||||||

Φ40 | 263 | |||||||

Φ50 | 513 | |||||||

Φ60 | +3 -2 | 888 | ||||||

Φ70 | 1410 | |||||||

Φ80 | 2104 | |||||||

Φ90 | 2996 | |||||||

Φ100 | 4110 | |||||||

Φ110 | +4 -2 | 5457 | 50-60 | |||||

Φ120 | 7102 | |||||||

Φ130 | 9030 | |||||||

Φ140 | +4 -3 | 11278 | ||||||

Φ150 | 13871 | |||||||

Casting Grinding Balls:

Chemical Composition of Casting Grinding Ball:

Item | Chemical Composition(%) | ||||||||

C | Si | Mn | Cr | P | S | Mo | Cu | Ni | |

| | 2.0-3.0 | ≤0.10 | 0.5-1.5 | 10-14 | ≤0.10 | ≤0.10 | 1.0Max | 2Max | 0-1.5 |

High chrome cast grinding balls | 2.0-3.0 | ≤0.10 | 0.5-1.5 | 14-17 | ≤0.10 | ≤0.10 | 3.0Max | 1 Max | 0-1.5 |

2.0-2.8 | ≤0.10 | 0.5-1.5 | 18-22 | ≤0.10 | ≤0.08 | 2.5 Max | 1 Max | 0-1.5 | |

2.0-2.8 | ≤0.10 | 0.5-1.5 | 22-28 | ≤0.10 | ≤0.08 | 3 .0Max | 2 Max | 0-1.5 | |

Middle Chrome Cast Grinding Balls | 2.1-3.2 | 0.5-2.2 | 0.5-1.5 | 6~10 | ≤0.10 | ≤0.10 | 0-1.0 | 0-0.8 | 0-1.5 |

Low Chrome Cast Grinding Balls | 2.2-3.6 | ≤1.2 | 0.5-1.5 | 1.0-3.0 | ≤0.10 | ≤0.10 | ≤0.10 | 0-0.8 | -- |

3. Packing for Grinding Media Ball with High Performance & Competitive Price

4. Testing for Grinding Media Ball with High Performance & Competitive Price

- Q: There is a little trace of polishingShock polishing is even worseElectrolysis can not be uneven, there is a slight bump

- Buffing should be better, to see how your embryo, but a bit difficult

- Q: What are the casting parts used to test shrinkage holes?

- 2. x ray. This method can do nondestructive testing, but the cost is higher. Generally, high castings are required.

- Q: How is the silicon sol precision casting part priced? What is the price per ton of casting? Such as 304 material.

- I am doing this for sale, if the price is mainly based on the product structure, the difficulty of pricing. At present, if it is more formal and material guarantee manufacturers generally in 48-53 yuan /Kg (of course, products have a certain weight, such as greater than 100g), our company's current price of about 53 yuan /Kg or so. .

- Q: our factory now produces steel castings in the use of polishing directly after spraying processing, but the powder sprayed 15But the spray powder touched off what is the reason we are not very strict requirements not only need to peel off bubbles can also, because our products are steel castings so we use steam hole sludge put on. Do not know if this spray treatment has no effect to thank friends with us!

- Cast iron has not been done, if it is iron, then in the spray before going through strict pretreatment, the surface can not have a little oil dust

- Q: Explain the heat treatment effect of casting parts, forging parts and welding parts

- The three methods of metal processing have one thing in common. They are hot working, which are different in temperature and range of processing. Ductile cast iron is widely used because of its brittleness and poor impact. Heat treatment of cast iron usually adopts the annealing process, reduce the casting effect: 1 because of the internal stress caused by the thermal expansion and contraction, reduce the deformation after machining, decrease surface hardness, improve machining conditions;

- Q: Is the cast steel a casting part?

- Cast steel is one of the casting parts that you call. The material is made of carbon steel or alloy steel, stainless steel, etc. the method is cast

- Q: In theory, which is more expensive, forging parts or casting parts?

- It depends on the structure. In theory, the shape of the forging is relatively simple, but the requirement of internal structure is relatively high

- Q: I often see Waixiejiagong drawings, casting, how to distinguish the latheman.

- Yes, casting drawings are casting drawings with machining allowances, slopes, and gating systems

- Q: Is 316 casting better than 304 casting?

- It is comprehensive. There is no simple comparison of the material to determine the degree of difficulty in processing

- Q: What's the cause of the choking of the casting?,

- 2. when casting mold exhaust condition is not good, in the casting material use consider whether and hinder its gas permeability; in the process to consider to release more pores, multi venting; core exhaust is particularly important.

1. Manufacturer Overview

| Location | Zhangqiu, China |

| Year Established | 1995 |

| Annual Output Value | 150,000M.T. |

| Main Markets | 40%,South America; 30%,South Africa; 15%,Southeast Asia; 5%, Europe Area; 5%, North America; 5%, Other Areas |

| Company Certifications | ISO9001:2008;SGS Test Report |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao;Tianjin |

| Export Percentage | |

| No.of Employees in Trade Department | 25 |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 68,000m2 |

| No. of Production Lines | 15 |

| Contract Manufacturing | |

| Product Price Range | $700/M.T.-$1200/M.T. |

Send your message to us

Grinding Media Ball with High Performance & Competitive Price Used for Metal Mine/Cement Plant/Water Coal Slurry/Power Station/C

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords