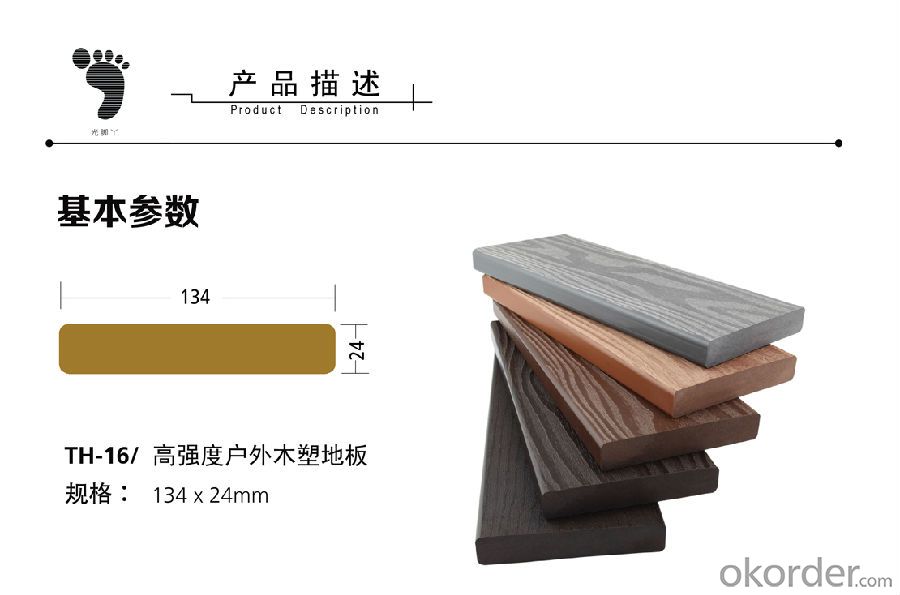

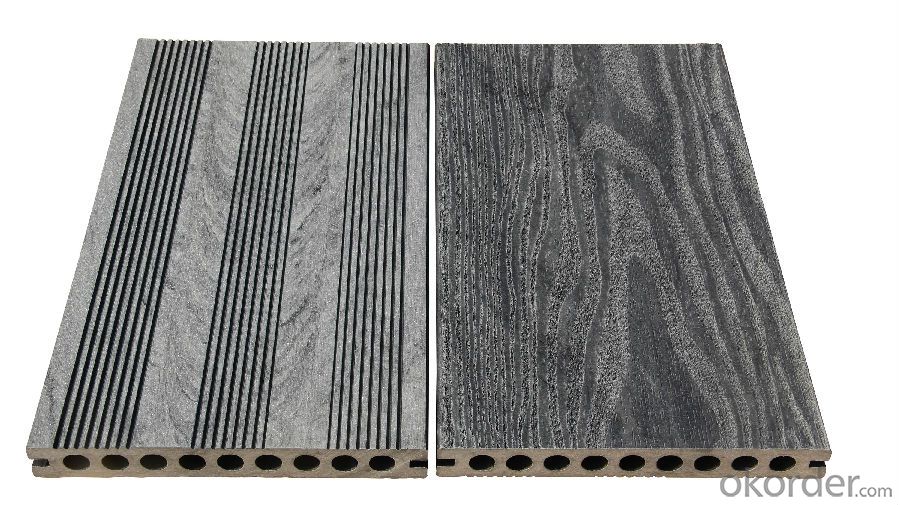

COOWIN outdoor wood plastic solid floor

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product structure description:

Barefoot wood plastic is a combination of natural wood fiber and eco-friendly plastic polymer. It is a composite material. The manufacturing process is wood powder plastic and the required coupling agent and additives. It is fully mixed under high temperature and high pressure. Extruder extrusion is cooled. The barefoot control of the raw materials is extremely strict. The raw material of the wood fiber in the product is 80 mesh aspen wood powder is uniform and fine; the plastic polymer uses high density polyethylene; the US DuPont import auxiliaries; the first-class raw materials for the future The mechanical properties of the formed product provide a strong guarantee to ensure the stability of the product.

Main features of the product:

1. Strong bending strength (compressive ability) and high weather resistance:

We insist on the use of high quality HDPE (High Density Polyethylene), which has higher crystallinity than ordinary plastics on the market (low density, medium density) and thus exhibits higher strength. The process of rotation from the molten state to the solid state takes some time to eventually form crystals. HDPE undergoing this process will achieve higher shrinkage, 2-3 times the tensile strength of LDPE (low density polyethylene) and a compressive strength of 4600 psi. At the same time it has good heat resistance and cold resistance.

Weather resistance: good performance from minus 40 degrees to over 60 degrees

2, waterproof and moisture resistance:

3. Photooxidation and fading (anti-fading);

4. Effectively prevent oxidation and breakage, and have a long service life;

5, effective slip resistance;

6, no need to paint maintenance costs are low:

Get competitive prices from our large capacity. At the same time, the large capacity of the factory can be delivered quickly.

. No formaldehyde or harmful substances.

. Environmentally friendly products, the government vigorously promoted.

- Q: How to polish the floor

- Floor care essential oil, the more rub the more bright

- Q: Will the composite floor be faded for a long time?

- Will the composite floor be faded for a long time?

- Q: In the old composite wood flooring and then add a layer of elephant composite wood flooring is possible, will not exceed the formaldehyde content

- Any brand of any floor will contain formaldehyde, formaldehyde not only from the glue, but also from the paint. Formaldehyde emission in accordance with national enforcement standards is 1.5mg / L, better than this standard Caixing. Decoration process, you can release a lot of formaldehyde things, such as home, carpentry, paint ... ... it is inevitable to ensure that the standard. You can ask the business, floor production is used in what glue, such as water-based glue and the like. General water-based plastic market price in 2000 or so a ton, and professional floor glue about one ton, such as the international market more professional floor glue is Finland's Tail glue. And paint, then, relatively good is the German Fu Fu paint.

- Q: Solid wood flooring and solid wood composite floor What is the difference

- Multi-level layers of solid wood a piece of wood? Sure what is good

- Q: 100 locusts know Hao version of Tongbao Kun ready to buy wood flooring, a friend said that the composite floor of the radiation formaldehyde or something. Answer, the composite wood floor with radiation and formaldehyde? How to identify and buy more environmentally friendly wood flooring more

- Home furnishings or 100 locusts know Hao version of Tongbao Kun with solid wood flooring, or with tiles. Composite wood flooring is a commercial, the indoor air dip or more serious. Pollution mainly from the floor of the adhesive in the benzene compounds, the human organs caused irreversible damage. Formaldehyde harm is very small, only 10% of the total pollution is less than.

- Q: Home cat, bouncing time there will be a sound, when the rent when the house felt a lot of sound, and now the new house decoration, please give pointers about what the floor noise to do? The price is what kind of ridicule reminders 诎 nine back to the end of the end, answer satisfaction will be added high score. More

- Foam board the best, cheap, first do waterproof, and then shop the bubble, the specific price of the local decoration works team, the region and other reasons will cause the price deviation, fear of being slaughtered, ask a few is it. When asked about the difference between the material, the difference between the process.

- Q: What is the difference between composite flooring and tiles?

- To the occasion, the general bedroom and study more suitable for wood flooring. The kitchen, the bathroom is more suitable for tiles. One: tiles: tiles are often said floor tiles. Tiles are cheap, and easy to clean and clean, tiles are also wear-resistant. However, the tiles of the foot feel and decorative effect as wooden floor. Second: wood flooring: wood flooring is divided into solid wood flooring, parquet. 1) solid wood flooring: solid wood flooring is very healthy, environmental protection, decoration effect is good. In the price is more expensive, and not easy to install and maintain, need regular waxing. 2) parquet: solid wood flooring changed the previous physical structure, better stability. In the price, than the solid wood flooring to be cheaper, are middle consumer products. Is the home decoration in the more popular a class of ground decoration materials. 3) to strengthen the floor: to strengthen the floor is the biggest feature of wear resistance is good, very suitable for living room and other places more concentrated, is the wood floor varieties in the cheapest floor, is the working class people first floor decoration materials. However, in the installation and maintenance is very simple.

- Q: If you want to shop on the original floor with laminated flooring what needs attention?

- 1, the original floor is a tile or composite floor, if the tile can be directly shop, but in the kitchen and bathroom joints to seal, to prevent moisture into. 2, if it is on the floor and then shop, to ensure that the original floor smooth, dry, because a number of the bottom floor deformation, the upper floor will be deformed. At the same time also consider the floor increased, the door should be shortened, the composite floor and the original tile floor of the convergence problem. (1) Solid wood floor flatness: If it is very narrow old wooden solid wood flooring, if there is uneven treatment. Such as loose, fixed firmly; if it is Alice, you can planing. Or simply remove one or two pieces, because the smaller area, does not affect the composite floor pavement. If it is wide board, to plan to deal with good. (2) check whether the sound of solid wood flooring, what causes, loose keel or loose floor. (3) keel integrity. Check the keel is loose, there is loose, to re-reinforcement; check whether there is rot, if the decay of aging, replace the new keel. Because the joint effect, if the keel is not good, will have a new composite floor impact. (4) all with more than a few years of solid wood flooring, in the floor before the composite floor, it is best to use the United States solid nail keel reinforcement.

- Q: Multilayer solid wood flooring with composite flooring which is good

- Mainly depends on which side you are more than the fear of Cao Cao 丨 meter investigation of the intestines than the Ka floor to give you the answer, if the overall cost is concerned, multi-layer solid wood flooring better than the laminate flooring, the main reasons are the following 5 points: 1, multi-layer solid wood flooring stability than the floor is better. 2, multi-layer solid wood floor foot feel better than the floor is better. 3, multi-layer solid wood floor of the skin of the natural texture of wood is to strengthen the floor is not. 4, multi-layer solid wood flooring moisture and anti-geothermal performance than to strengthen the composite floor is better. 5, multi-layer solid wood flooring surface wear as hard as the composite floor, and the price is more expensive than laminate flooring.

- Q: Because it is a newly renovated house has not moved Dinghu guilty cunning Chong twisted anchor into the floor flooding degree is relatively large, the water leaked 2 days to find the water seepage downstairs walls, paint are blasting Please come after the sale Treatment is to dig out the most serious part of the flooding, the rest do not deal with such water vapor their own volatile I would like to ask those who do not need to replace those soaked in the future will not mold mold, smell out of the problem added: Smell it? Plastic film must have been soaked, is not going to penetrate into the floor inside? More

- Will the floor soak for two days? We all know that woody things are afraid of water? I do not believe Bei Yake can withstand the blisters, I am afraid that one day there is a problem, the elephant bubble two days yet full reimbursement quality is pretty good. Patiently waiting, naturally dry no problem, since the choice of the elephant will believe it.

Send your message to us

COOWIN outdoor wood plastic solid floor

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches