WPC outdoor wood plastic floor wood plastic composite

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

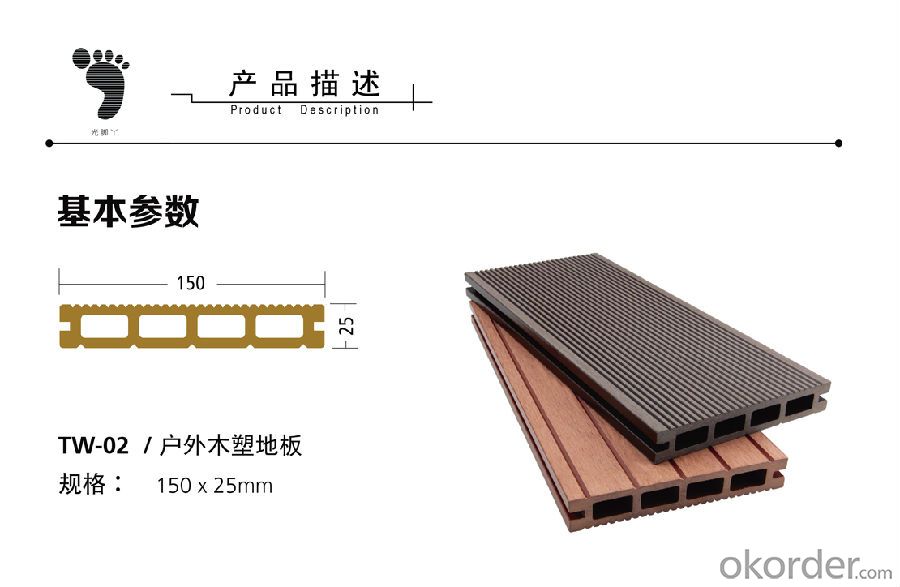

This is an outdoor hollow wood-plastic floor with two anti-skid grooves, one side of 26 slots and one side of 5 slots, with anti-slip function. This product is ideal for outdoor terrace decoration, roof decoration, garden decoration, outdoor pool plating and other projects. This is a very popular and cost-effective affordable wood-plastic floor. Welcome to buy.

Product structure description:

Barefoot wood plastic is a combination of natural wood fiber and eco-friendly plastic polymer. It is a composite material. The manufacturing process is wood powder plastic and the required coupling agent and additives. It is fully mixed under high temperature and high pressure. Extruder extrusion is cooled. The barefoot control of the raw materials is extremely strict. The raw material of the wood fiber in the product is 80 mesh aspen wood powder is uniform and fine; the plastic polymer uses high density polyethylene; the US DuPont import auxiliaries; the first-class raw materials for the future The mechanical properties of the formed product provide a strong guarantee to ensure the stability of the product.

Main features of the product:

1. Strong bending strength (compressive ability) and high weather resistance:

We insist on the use of high quality HDPE (High Density Polyethylene), which has higher crystallinity than ordinary plastics on the market (low density, medium density) and thus exhibits higher strength. The process of rotation from the molten state to the solid state takes some time to eventually form crystals. HDPE undergoing this process will achieve higher shrinkage, 2-3 times the tensile strength of LDPE (low density polyethylene) and a compressive strength of 4600 psi. At the same time it has good heat resistance and cold resistance.

Weather resistance: good performance from minus 40 degrees to above 60 degrees

2, waterproof and moisture resistance:

3. Photooxidation and fading (anti-fading);

4. Effectively prevent oxidation and breakage, and have a long service life;

5, effective slip resistance;

6, no need to paint maintenance costs are low:

Get competitive prices from our large capacity. At the same time, the large capacity of the factory can be delivered quickly.

. No formaldehyde or harmful substances.

. Environmentally friendly products, the government vigorously promoted.

- Q: Decoration commonly used plate brand?

- Top 10 brands of board-off woodworking board Hebei Tengfei Wood Co., Ltd. is a private joint-stock enterprises, which was established in 1996, more than 800 employees, mainly engaged in sheet, multilayer, Glulam R & D and production. Plate top ten brands of Peng Hong. Dalian Peng Hong Wood Co., Ltd. was founded in 1997, is China's wood-based panel industry leader. The company's comprehensive production capacity and product sales in the domestic wood-based panel manufacturing industry in a leading position in the domestic market enjoyed a high reputation. Top 10 brands of Albert. Guangzhou Wei Zheng Wood Products Co., Ltd. was established in 1996, is a professional production of "Wei-licensing" green plywood of wood products large enterprises. The company has been committed to improving the human living environment, to create a harmonious home, tree industry standards, has made brilliant achievements.

- Q: What is the difference between steel sheet and coil?

- The plate is finished after the roll processing

- Q: Buy plate three errors is what?

- At present, consumers themselves have many misunderstandings about the purchase of plates: ????"Trimming smooth and smooth plate must be good." This is not true. Perennial deal with the plate of a home improvement company boss said that the more such a plate of consumers more careful, trimming is generated when the machine sawing, good plate generally do not need "re-processing", often a lot of stubble child. But the quality of the plate because of its internal is empty, black core, so the processor will "deliberately dress up" it, in the trimming and then paste a "nice" wood, and polished smooth neat, to confuse the consumer , So you must not use this as a standard to measure what is good or bad. ????"3a is the best." Some readers reflect that they are doing the decoration in order to no problem, only selected marked "3a level" of the plate, the result is still a problem. In fact, the national standard is not "3a", but the business or business personal behavior, can not guarantee its quality. Currently on the market has not allowed the words, the detection of qualified wood will be marked "excellent goods", "first-class goods" and "qualified products." ????"The heavier the better plate". This view is absolutely incorrect, the insider to buy a look at the degree of drying, two see splicing. Good dryness of the plate is relatively light, and there will be no cracks, very smooth. For outsiders of consumers, the safest way is to reliable building materials market, buy some well-known brands of plates. In order to prevent some of the counterfeit products on the market, you must see whether the purchase of a national authority issued by the test report once the problem is also well documented.

- Q: How much is the quartz stone plate? What is the specification?

- Zircon 2.4x0.75, one centimeter five, how much money one

- Q: Bunny plate environmental protection China line advertising

- Actually become such a sheep to eat it, she said the company is scheduled to cheat, people fooled to distant remote exhibition to ask her reason, long mind people know that this is a guise price activities, everyone only A live card on the 50, and a variety of Huyou, I would like to ask the head office you really is a set of online, said a good 50 yuan so-called activity card into 100, the day to so many people , Can imagine how much the income

- Q: Do not understand why this size? What is the convenience?

- This is often said that four or eight feet specifications. Where the foot is feet, 1 foot = 0.3048 meters, So four or eight feet is 1.2192 meters x2.4384 meters, Which is nearly equal to 1220x2440mm.

- Q: High voltage switchgear shell plate thickness

- I really switch cabinet manufacturers work I do not know about other units, I know Our unit is 2 to 3 mm or so, the material is Complex aluminum zinc plate

- Q: What brand of furniture is good?

- Of course, is the choice of imported sheet is better, the furniture environmental performance is mainly reflected in the plate, a good plate formaldehyde content is particularly low, mainly divided into three, E2 level which is in line with domestic standards, E1 level in line with European standards, E0 level is the most Environmental protection of the world's top standards. Like Amoy home now launched the import board furniture package, have reached the EO level of the standard, recently also promotions, buy environmentally friendly furniture to pay attention to the issue, the first look at the color of the plate, pick their favorite popular colors, But also carefully look at the production process, including the edge, the furniture structure is reasonable, the use of hardware mainly focus on the durability factor, the general import of hardware life is 100,000 times, equivalent to two decades.

- Q: What kind of sheet is durable?

- Cut a small piece from the plate (10 cm X20 cm) in boiling water for 20 minutes, if not deformed quality is very good.

Send your message to us

WPC outdoor wood plastic floor wood plastic composite

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords