WPC outdoor wood plastic solid floor new environmentally friendly composite material

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

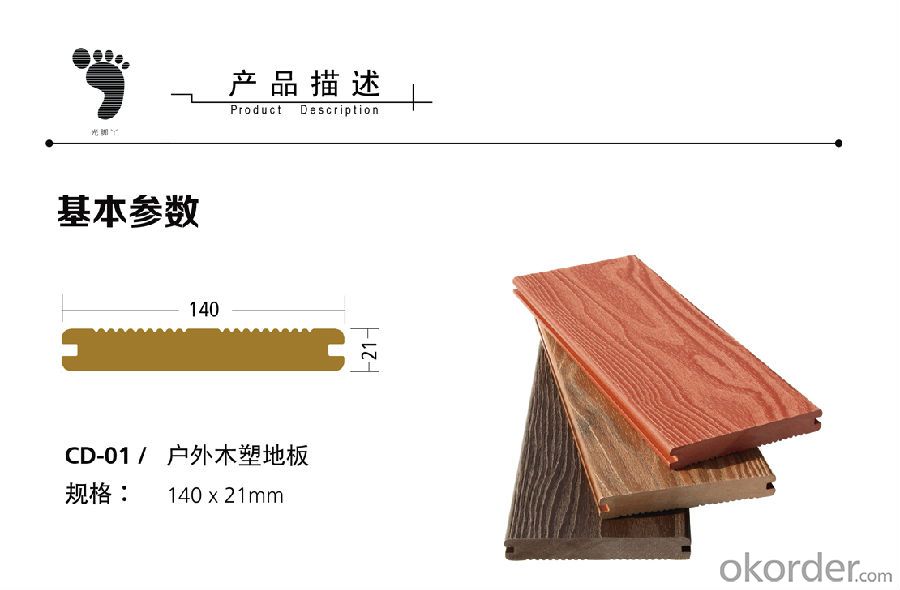

Specification

This product is 140*21mm solid wood-plastic floor and has a bending resistance of 4375KN. It is very suitable for park greening, landscaped wooden plank paving, outdoor swimming pool decking and coastal dock decking. One side has a non-slip groove design to prevent slipping, and it is not comfortable to step on the bare feet. It feels very comfortable!

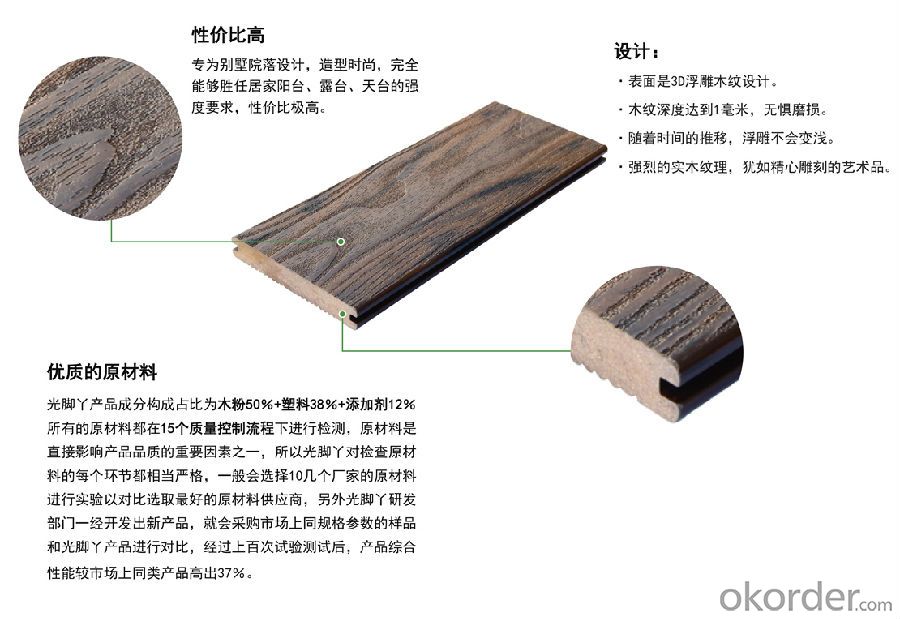

Product structure description:

Barefoot wood plastic is a combination of natural wood fiber and eco-friendly plastic polymer. It is a composite material. The manufacturing process is wood powder plastic and the required coupling agent and additives. It is fully mixed under high temperature and high pressure. Extruder extrusion is cooled. The barefoot control of the raw materials is extremely strict. The raw material of the wood fiber in the product is 80 mesh aspen wood powder is uniform and fine; the plastic polymer uses high density polyethylene; the US DuPont import auxiliaries; the first-class raw materials for the future The mechanical properties of the formed product provide a strong guarantee to ensure the stability of the product.

Main features of the product:

1. Strong bending strength (compressive ability) and high weather resistance:

We insist on the use of high quality HDPE (High Density Polyethylene), which has higher crystallinity than ordinary plastics on the market (low density, medium density) and thus exhibits higher strength. The process of rotation from the molten state to the solid state takes some time to eventually form crystals. HDPE undergoing this process will achieve higher shrinkage, 2-3 times the tensile strength of LDPE (low density polyethylene) and a compressive strength of 4600 psi. At the same time it has good heat resistance and cold resistance.

Weather resistance: good performance from minus 40 degrees to above 60 degrees

2, waterproof and moisture resistance:

3. Photooxidation and fading (anti-fading);

4. Effectively prevent oxidation and breakage, and have a long service life;

5, effective slip resistance;

6, no need to paint maintenance costs are low:

Get competitive prices from our large capacity. At the same time, the large capacity of the factory can be delivered quickly.

. No formaldehyde or harmful substances.

. Environmentally friendly products, the government vigorously promoted.

- Q: EVA is not a gospel warrior, rubbing experience can leave. Saying that my road has a curvature, how to make EVA board stereotypes. The The With the hair dryer are hot and did not respond. The The Is it my fault? And if the use of epoxy resin or atomic ash how to use Thank you to answer, rub the experience of the chat there are simply do not know the cloud of the shotgun wait. The The I want a ...

- EVA I have seen only 3 mm 5 mm 1 cm 2 cm 3 cm thick ? EVA several polishing Do not want the final product to look very smooth, evenly colored, one to two colors dry after the spray varnish BR /> with the ordinary knife and scissors cut We generally use the universal adhesive EVA is still very strong

- Q: Q235 sheet of the label

- Q235 hot-rolled plate: the molecular standard for the standard: 3-GB / T 709-88; denominator for the acceptance criteria: Q235-GB / T 700-88 Q235 cold-rolled plate: the molecular standard for the standard: 3-GB / T 708-88; denominator for the acceptance criteria: Q235-GB / T 700-88

- Q: Black box plate glasses for what kind of person

- To wear black-rimmed glasses actually require quite high Look at the face and color

- Q: KT board is what plate ah? Generally used in where the best picture to explain do not copy copy! To be original

- Third, kt board classification: Kt board mainly cold plate and hot plate two. Kt cold plate and kt hot plate is the biggest difference between the process in the laminating and the difference between the plate itself, the cold plate for the pvc film, composite film process for the cold composite. Hot film is the ps film, the composite process for the thermal composite. As for the first time ps particles foam out of the thickness of the difference between the plate now has no technology, a few years ago, the price of raw materials ps expensive, in 2008 began to double the price of raw materials, the general manufacturers will not be there Do cut corners of the article, and now kt plate manufacturers foam sheet out of the thickness of the sheet, more importantly, the weight of the sheet, this is the key to determine the core hardness. At present kt board in addition to cold plate and hot plate classification, can also be divided into: silk screen kt board, mounted kt board, paper kt board, high density kt board, color kt board, export grade kt board, The

- Q: Although the overall wardrobe in recent years in the rise of the country, but its development is very fast, and has long been a modern 80,90 home improvement after their favorite clothes storage products, but can be used to make the overall wardrobe plate quite much, For all kinds of products, as a layman of the consumer how to identify the pros and cons of wardrobe plate it? Well-known overall wardrobe business - the Federal Shangguan Road wardrobe business Xiaobian here for you to carry out the following Weapon, hoping to help more potential consumers of the overall wardrobe to understand this related knowledge. , Is the overall wardrobe is necessary, in the purchase of the whole wardrobe, the plate is a direct impact on the overall quality of the final wardrobe effect, for those who do not understand the board is not a friend , How to determine the quality of the plate it?

- Second, look at the wardrobe is the use of high-density board or particleboard, the method is to determine the cut from the plate to see, high-density board inside the small fibers closely together, the density, heavier. High density board can withstand greater pressure, longer service life; and particleboard fine particle structure is not close enough, and even can see small pores, placed in the hands of light, bear the small gravity, short life.

- Q: How to identify the custom wardrobe or cabinet plate is large Asia E0 grade plate

- First look at whether it is a large Asian plate of formal authorized business, there is no authorized certificate. Then there should be a large board on the board logo.

- Q: Willow eucalyptus wood and pine which is good

- Pine better, you can do furniture directly, Eucalyptus urophylla is just the core of the blockboard ah ~ ~

- Q: Pc plate and memory board comparison, which is good?

- PC board is a polycarbonate as the main component, the use of co-extrusion technology CO-EXTRUSION made of a high-quality sheet. Because of its surface covered with a layer of high concentration of UV absorbers, in addition to the characteristics of anti-ultraviolet and can maintain long-term weather, never fade. Memory plate toughness is relatively large. Select these two plates according to your needs.

- Q: TR90 material, in the glasses frame classification inside the plate or injection molding rack

- I am engaged in glasses for 10 years, I have to answer your question, TR90 material is also called nylon material, I can certainly tell you is injection molding rack. Plate frame glasses is the color of the existing color of the CP material plastic plate, polished by the lathe polished drum and other processes produced, the advantages of bright colors and natural color stripes will never fade, the disadvantage is the material is more brittle, easy to crack deformation. Injection molding frame glasses, is the use of plastic particles after injection molding, grinding drum polishing and other processes made of color, the advantages of fashion, fashionable, fine workmanship, the choice of material wide (with CP material TR90 material sub-feeding material just expected rubber Materials and other materials produced) which TR90 material is nylon material is better, strong and durable, tough. Distinguish between glasses and glasses, see color stripes, plate frame glasses, color stripes in the material inside. Injection molding glasses, color stripes are in appearance.

- Q: Home improvement plate which brand the best ah? Environmental protection best?

- Like this kind of furniture plate material quality is good, only used to know, Fuxiang plate can be considered a very large enterprise in Hunan Province, and has been a good quality itself, you can personally go to their stores to see ah. Online question is also asked not to experience in order to understand!

Send your message to us

WPC outdoor wood plastic solid floor new environmentally friendly composite material

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords