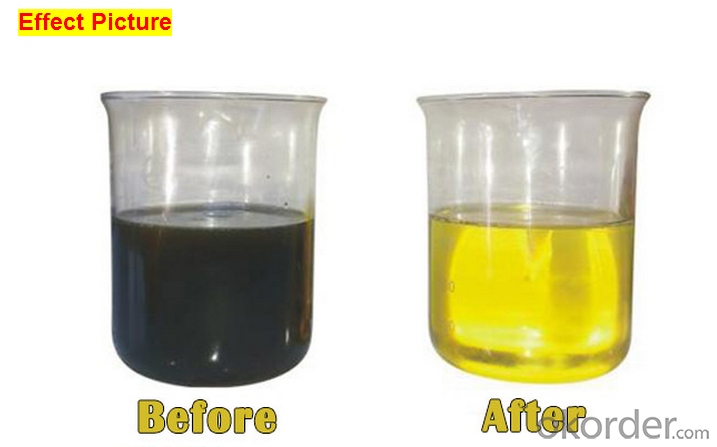

Cooling and Lubricating Oil Regeneration Machine, Eliminates Residue on Parts , Extend Coolant Life

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | wooden case |

| Delivery Detail: | 10 days |

Specifications

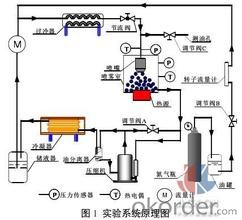

TYA series cooling and lubricating oil regeneration machine

1.Eliminates residue on parts

2. improve oil performance, low cost

TYA series cooling and lubricating oil regeneration machine

oil purifier, oil filtration, oil purification, oil filter,

oil treatment, oil saving, oil recycling, oil processing,

oil filtering, energy saving, oil regeneration, oil processor,

oil filter, oil process, oil purify, oil regenerating,

oil restoration, waste oil disposal, oil reclaimed, oil

reclaiming, waste oil management, oil regenerate, oil

reconditioned, oil reconstituted, oil restituting

TYA Water Oil Separator

#1 More separation volume and more coalescing media combined

with lower separation velocity at higher flow rate.

#2 The micro adjustable conical oil outlet weir allows visual

inspection of oil quality and dryness. The stainless steel handle

keeps your hands dry too.

#3 The TOP skimmer head works on the principle of a positive

buoyancy radial flow weir coupled with a floating or fixed combination

center sump and weir guide to effectively remove the oil or other light

immiscible liquids from the surface of the water.

Eliminates residue on parts

Reuse wash water

Reduce or eliminate disposal

Extend coolant life

Improve toll life

Improve part quality

Eliminates foul odors

Minimizes Dermititus

Reduce coolant purchases

Reduce disposal costs

Reduce compliance costs

Table1 TYA Oil Purifier Treated Guarantee Value

Item | Guarantee indexes |

Moisture content | ≤50 PPM |

Demulsification value | New oil≤15min,running oil≤30min |

Impurity size | ≤1 micron |

Gas content | ≤0.1% |

Clean degree | ≤4 Grade (NAS1638) |

Machine Technology

Dehydration (Degas) System

The duplex-stereo vacuum evaporation vessel can enlarge evaporation area

efficiently. The heater, being placed on the duplex-stereo vacuum evaporation vessel, becomes an evaporator. Thus the

evaporation area of duplex-stereo vacuum evaporation vessel is three

times more than that of

the common vacuum vessel. This innovation can dehydrate and degas

effectively and efficiently.

The optimal structure of the dehydration (degas) system enlarges the

surface area of oil exposed to the vacuum system and extends the

flowing distance of the oil in the vacuum system. Thus there has

sufficient time to remove the moisture and gas from the oil by vaporization.

•Filtering System

The filtering materials with variable apertures are made of specialized

glass fiber. The sizes of the filtering fiber and aperture dwindle

gradually in the different filtering stages. The impurities with different

particulate sizes are filtered step by step. The capability of removing

particulate matters and impurities is improved greatly by this method.

The filtering system has stable and perfect filtering fineness. The

filtering fineness has several grades, including 1, 2,3,4,5,6,10 µm etc.

Oil β≥1000 after filter.

The filtering system is equipped with reverse rinse and filth device.

It improves the effectiveness of filtering and extends the lifetime of

filter awfully.

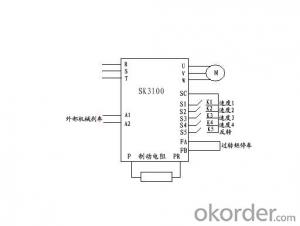

• Electrical Apparatus controlling System

The main components of the electrical apparatus made by Siemens Company

ensure the safety of the controlling system. Having several protection

systems which will avoid oil ejection, overload and over voltage etc.

• Oil heating System

The unique heater structure heats the oil uniformly.

Oil Heater System assures less than 1.0 w/cm². During the heating

process, the deterioration of the oil caused by overheating is avoided.

The oil temperature can be adjusted between 0℃ to 100℃.The heater is

controlled manually or automatically. The heater will stop automatically

when the oil temperature reaches a certain degree.

Being installed with safety protection devices, the heating system is

secure and reliable. The heater will stop operation automatically when

the oil volume of inlet is too low to avoid the damages of the heater.

• Oil-level Controlling System

The oillevel floating ball and infrared liquid level automatic

controller system are installed in the vacuum vessel to control the

oil level so as to avoid the oil leaking in the operation.

The new innovation of eliminating froth can avoid the oil ejecting

and gushing during the process

• High quality components

The main component parts of our products such as vacuum pump, oil

pump and electric apparatus are from SIEMENS, ABB, SCHNEIDER and

AMICO etc. It ensures our products high quality and reliability

• Structure and appearance of Oil purifier

Our products adopt ship-shape chassis-mount structure to ensure oil leak proof and protect the environment

from pollution.

The whole equipment is characterized by small size, light weight and

convenient to move around.

Various sizes and configurations(alloy shield) available

Available in mobile or stationary options

Automatic vacuum oil purifier or anti-explosion vacuum oil purifier is both available according to customers’ needs.

FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: I have a full-time job but would like to dabble in residential electrical work for friends and family. What would I need to do? I would like some kind of formal license and training but don't want to go back to school or commit to any long-term programs. This is in Massachusetts.

- You would need a license to do work for others. You MAY find internet classes but still need to take a State test. Then there is the insurance angle. Doing electrical work for others could cost you a whole lot if there is a problem. Friends and relation are the first to sue when there are problems.

- Q: i just got into tech school for USAF as an aerospace ground equipment apprentice and was wandering if this is a good job? what kind of things can i expect to be doing everyday? is there a good chance i will get deployed to iraq? i would appreciate any advice anyone has. thanks

- It's a GOOD starting point for an apprentice space cadet! in 2 years you'll be a full pledged SPACE COWBOY! GOOD LUCK! the USAF needs MEN like you!

- Q: Can I use GB electrical equipment in Ukraine? If not what adaptor do I need to be able to use it?

- Ukraine has 220/240 voltage, and a different 3 prong outlets. You can buy converters in most major stores.

- Q: every electrical equipment is rated in VA or KW(motor) why transmission line rated in Volts though it carry power.

- Because voltage is the only thing that remains fairly constant. Even though industry and residential pull off that transmission line, the voltage is and Hertz is maintained for the sake of equipment that depends on a constant voltage. The current in the line fluctuates highly , depending on how many people are drawing on it at any instant

- Q: I am interested in buying a house and the village water supply enters the house right next to the electrical panel in the basement. I am concerned that this might be a code violation and not pass inspection. Any thoughts?

- The six foot distance is for entrances, not equipment. (Betcha your electrical service enters overhead). In any event the existing installation is Grandfathered as Richard states. With an old house, it is prudent to make any pre-purchase agreement contingent upon passing an inspection. (You should get one done before closing. You're spending a lot of $. Don't skimp here.)

- Q: i am instrument electrical eng.student and i am about to take 2 of the 4 subject for electives, here the subject:1)process control2)automation and robotic3)measurement and instrumentation4)control system 3i am thinking to involve in maintainance,oil and gas or maybe aircraft maintainance.after grad.what is the subject is suitable and what is the subject advantage and disadvantage. i want get some advice before make the decision.tq

- Well. it is very good major Oil and Gas companies need ur major since the instrumentation is controlling the whole units. Huge Essential System and very critical in any refinery such as: DCS : Digital Control Center. ESD: Emergency Shutdown. UPS: Uninterrupted Power Supply ( Electrical Equipment feeds instrument load) I think u have a bright future with this discipline if you have interests . And regarding these Subjects, i dont know much about control All the best

- Q: give formulas and explanation both

- In general, mechanical efficiency is the ratio of the work input to the work output. There is always some frictional looses that require extra work input to overcome. Electrical efficiency is the ratio of power input to power output. There are always copper losses in any electrical equipment. These are basic differences and definitions. The basic formulas are efficiency output / input, using either work or watts. TexMav

- Q: definition

- *Many electrical installations have a relatively high earth impedance. This may be due to the use of a local earth rod (TT systems), or to dry local ground conditions. These installations are dangerous and a safety risk if a live to earth fault current flows. Because earth impedance is high, 1. not enough current exists to trip a fuse or circuit breaker, so the condition persists uncleared indefinitely 2. the high impedance earth cannot keep the voltage of all exposed metal to a safe voltage, all such metalwork may rise to close to live conductor voltage. These dangers can be drastically reduced by the use of an ELCB or Residual-current device (RCD). The ELCB makes such installations much safer by cutting the power if these dangerous conditions occur. This approach to electrical safety is called EEBAD. In Britain EEBAD domestic installations became standard in the 1950s. In non-technical terms if a person touches something, typically a metal part on faulty electrical equipment, which is at a significant voltage relative to the earth, electrical current will flow through him/her to the earth. The current that flows is too small to trip an electrical fuse which could disconnect the electricity supply, but can be enough to kill. An ELCB detects even a small current to earth (Earth Leakage) and disconnects the equipment (Circuit Breaker). Go through the source links. Also read and seach for residual current device.

- Q: highest Temperature i can reach in a lab with electrical discharge i do not care if the equipment gets destroyed or not i just want to know the possibility of the highest temperature you can reach with electricity if there is no limit then simply say no limit. if you know the best possible method please explain as much as possible. thanks in advance.

- There is a limit. The temperature of an electric arc (the plasma formed by an electrical discharge) is on the order of 10,000 C. This temperature is high enough to melt any substance known and to vaporize almost any substance known. Of course the amount of heat contained in that arc depends on a number of things like the amperage, the electrical power, and the material making up that plasma. You can produce an arc with a flashlight battery but the heat content of that arc is tiny. However, if you are a group of atoms of, for example, copper, participating in that arc, you are going to melt and some of you are going to vaporize. If you want to learn more about exotic ways to acheive very high temperatures (enough to initiate nuclear fusion), google the Lawrence Livermore National Laboratory and their project on laser ignition for fusion research.

Send your message to us

Cooling and Lubricating Oil Regeneration Machine, Eliminates Residue on Parts , Extend Coolant Life

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches