5052 H32 Aluminum Alloy Coil - Continuous Cast Aluminum Coil 5005 5052 5083 for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Continuous Cast Aluminium Coil 5005 5052 5083 for Building

Name | Aluminum Coil |

Brand | CNBM |

Alloy | 1100H-18, 3003-H24,3003-H26,3005-H26,8011,3004,3105,5005,etc. |

Thickness | 0.1~1.5mm |

Width | <2000mm< span=""> |

MOQ | 1 MT |

Coating finish | Brushed, drawing, embossed, printing |

Color | As to code RAL |

Surface | Embossed,Mill Finish,Coated,Brushed |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | PVDF27 ~35micron |

Polyester18~27micron(EN ISO-2360:1995) | |

Coating hardness | 2H |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

MEK resistance | 100 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 1MT - 2MT |

2. Application of Continuous Cast Aluminium Coil 5005 5052 5083 for Building

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Continuous Cast Aluminium Coil 5005 5052 5083 for Building

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

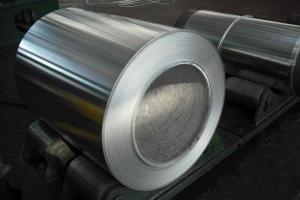

5. Image of Continuous Cast Aluminium Coil 5005 5052 5083 for Building

6. Package and shipping of Continuous Cast Aluminium Coil 5005 5052 5083 for Building

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the potential applications of laminated aluminum coils?

- Laminated aluminum coils have a wide range of potential applications. They can be used in industries such as electrical, automotive, aerospace, and construction. Some specific applications include electrical transformers, heat exchangers, automotive radiators, air conditioning systems, and architectural facades. The lamination process enhances the durability, heat and corrosion resistance, and electrical conductivity of the coils, making them suitable for various demanding environments and applications.

- Q: What’s the loss rate per kg when processing aluminum coil to aluminum sheet?

- 6.5kg/piece

- Q: What is the maximum width and thickness of aluminum coils?

- The maximum width and thickness of aluminum coils can vary depending on the specific requirements and capabilities of the manufacturer. However, generally speaking, aluminum coils can have a maximum width ranging from 36 inches to 72 inches or even wider. As for the thickness, it typically ranges from 0.006 inches to 0.25 inches. It is important to note that these dimensions may vary in different industries and applications, so it is always best to consult with the manufacturer or supplier to determine the specific maximum width and thickness that meets your needs.

- Q: How are aluminum coils protected against scratches and damage?

- Aluminum coils are protected against scratches and damage through several methods. One common method is the application of a protective coating or film on the surface of the coil. This coating serves as a barrier between the coil and any potential sources of damage, such as abrasion or impact. Another way to protect aluminum coils is by using a process called coil coating. In this process, the coil is cleaned, pre-treated, and coated with a layer of protective paint or resin. This coating not only enhances the appearance of the coil but also provides a protective layer against scratches and other forms of damage. Additionally, during the manufacturing and handling process, aluminum coils are often wrapped or packaged in materials that provide cushioning and protection. This helps to prevent any scratches or dents that may occur during transportation or storage. Lastly, proper handling and storage practices play a crucial role in protecting aluminum coils against scratches and damage. It is important to handle the coils with care, using appropriate equipment and techniques to minimize the risk of scratching or other forms of damage. Storing the coils in a clean and dry environment can also help prevent any potential damage. Overall, a combination of protective coatings, coil coating processes, proper handling, and storage practices ensures that aluminum coils are well-protected against scratches and damage, maintaining their quality and appearance.

- Q: Can aluminum coils be used for electromagnetic shielding?

- Yes, aluminum coils can be used for electromagnetic shielding. Aluminum is a good conductor of electricity and can effectively block or divert electromagnetic radiation. Its high conductivity and ability to create a Faraday cage make it a suitable material for shielding against electromagnetic interference (EMI) in various applications such as electronics, telecommunications, and power transmission.

- Q: Aluminium forms layer of aluminium oxide when exposed to air. This prevents further reaction.However, isn't aluminium oxide an amphoteric oxide that can react with both acids and alkalis?

- Like hell, it can.

- Q: Can aluminum coils be used in high-humidity environments?

- Yes, aluminum coils can be used in high-humidity environments. Aluminum is a corrosion-resistant metal, making it suitable for applications in areas with high humidity levels. The natural oxide layer that forms on the surface of aluminum acts as a protective barrier against moisture and prevents the metal from rusting or corroding. This makes aluminum coils a popular choice for HVAC systems, where they are exposed to moisture and humidity on a regular basis. Additionally, aluminum coils are lightweight, durable, and have excellent heat transfer properties, making them an ideal choice for various industrial and commercial applications in high-humidity environments.

- Q: How are aluminum coils used in the production of heat sinks?

- The excellent thermal conductivity and malleability of aluminum coils make them indispensable in the production of heat sinks. Heat sinks are designed to dissipate excess heat from electronic components like processors, integrated circuits, and power transistors. By using aluminum coils in the manufacturing of heat sinks, several key advantages can be gained. First and foremost, aluminum coils possess high thermal conductivity, enabling efficient heat transfer from electronic components to heat sinks. This is crucial for maintaining optimal operating temperatures and preventing performance degradation or permanent damage caused by excess heat. The high thermal conductivity of aluminum ensures quick dissipation of heat away from electronic components, preventing overheating. Secondly, aluminum coils are highly malleable, making them easy to shape and mold into various heat sink designs. Heat sinks come in different sizes and shapes, with the most common being finned heat sinks. Fins on the heat sink increase surface area, facilitating greater heat dissipation. Aluminum coils can be easily formed into these fin shapes, enabling effective heat release into the surrounding environment. Furthermore, aluminum coils are lightweight and corrosion-resistant, making them ideal for use in heat sinks. The lightweight nature of aluminum ensures that heat sinks do not add significant weight to electronic devices, which is especially important in applications with weight restrictions, such as aerospace or portable electronics. Moreover, the corrosion-resistant properties of aluminum guarantee the durability and longevity of heat sinks, even in harsh environments. In conclusion, aluminum coils are vital components in the production of heat sinks due to their high thermal conductivity, malleability, lightweight, and corrosion resistance. By incorporating aluminum coils into the manufacturing process of heat sinks, efficient heat dissipation and improved performance of electronic components can be achieved, ultimately extending the lifespan of electronic devices.

- Q: Are aluminum coils suitable for signage and advertising applications?

- Yes, aluminum coils are suitable for signage and advertising applications. Aluminum is a highly versatile material that offers several advantages for these purposes. First, aluminum is lightweight, making it easy to handle and install. This is especially beneficial for large-scale signage or advertising displays. Second, aluminum is highly durable and resistant to corrosion, ensuring that the signage or advertising materials will withstand the elements and maintain their appearance over time. Additionally, aluminum can be easily fabricated and customized to meet specific design requirements, allowing for creativity and flexibility in signage and advertising applications. Moreover, aluminum is a sustainable material that is recyclable, making it an environmentally friendly choice for signage and advertising projects. Overall, the characteristics of aluminum coils make them an ideal option for signage and advertising applications.

- Q: This question asks for a comparison of the costs involved in purchasing new aluminum coils versus recycling old ones.

- <p>The cost of buying new aluminum coil versus recycling old ones can vary significantly based on several factors including market prices, quality of the recycled material, and the cost of recycling processes. Generally, recycling aluminum is more cost-effective as it requires less energy and resources compared to producing new aluminum from raw materials. The cost of recycled aluminum can be as low as half of that for new aluminum. However, the exact cost will depend on current market conditions and the specific requirements of the aluminum coils in question. It's advisable to get quotes from suppliers and recycling companies to determine the most economical option for your specific needs.</p>

Send your message to us

5052 H32 Aluminum Alloy Coil - Continuous Cast Aluminum Coil 5005 5052 5083 for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords