Concrete Purline Machine with One Edge Taper

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Concrete Purline Machine with One Edge Taper

1. Structure of Prefabricated Concrete Purline Compression Molding Machine:

Prefabricated Concrete Purline Compression Molding Machine is our special developed products as results of our engineers research, with which 60%steel material will be saved compared with traditional revolving die method .Efficiency can be improved 3 to 5 times compared with conical die method, these machine are easy for operation and convenient for maintenance, products from these machines are in good quality, smooth appearance and accurate in size.

2. Main Features of Concrete Purline Machine with One Edge Taper:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

3. Concrete Purline Machine with One Edge Taper Images:

4. Concrete Purline Machine with One Edge Taper Specification:

Product name | Type | Productivity | Hole number |

Concrete purline machine | 60*120*140* | 1.3-1.5m/min | 4 |

Concrete purline machine | 60*130*150*4 | 1.3-1.5m/min | 4 |

Concrete purline machine | 60*140*160*4 | 1.3-1.5m/min | 4 |

Concrete purline machine | 70*150*170*2 | 1.3-1.5m/min | 2 |

Concrete purline machine | 80*160*180*2 | 1.3-1.5m/min | 2 |

Concrete purline machine | 60*110*130*4 | 1.3-1.5m/min | 4 |

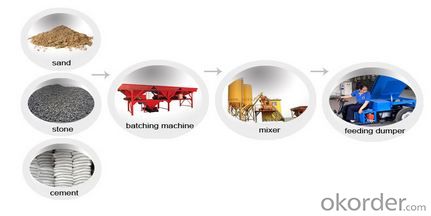

Production Process

Rebar tensioning

Raw materials preparing

Molding

Certificates

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. Customers from All Over The World

7. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

- Q: Any manufacturers or suppliers give the details of above matter in India

- Here's okorder /

- Q: Jan. 1 Retired a piece of machinery that was purchased on January 1, 2001.The machine cost$62,000 on that date. It had a useful life of 10 years with no salvage value.June 30 Sold a computer that was purchased on January 1, 2008.The computer cost $40,000. Ithad a useful life of 5 years with no salvage value.The computer was sold for $14,000.Dec. 31 Discarded a delivery truck that was purchased on January 1, 2007. The truck cost$39,000. It was depreciated based on a 6-year useful life with a $3,000 salvage value.InstructionsJournalize all entries required on the above dates, including entries to update depreciation,where applicable, on assets disposed of. Ingles Company uses straight-line depreciation. (Assumedepreciation is up to date as of December 31, 2010.)

- Interesting arguments, but I am not 100%

- Q: What is the best way to invent something? Like and industrial piece of machinery.?

- First get access to a workshop. And if you yourself are not an engineer or technical specialist, hire or recruit one (or more) to help you realise your idea.

- Q: What kind of materials can EDM machine

- Such as: hard alloy, hardened steel, graphite, aluminum alloy, structural steel, stainless steel, titanium alloy, diamond and other conductive body complex cavity and curved surface processing, all kinds of molds, electrodes, precision parts manufacturing,

- Q: Can you convert Auto Cad drawings not Inventor drawings to use with CAM & CNC software & Machinery?

- yes you can i took a AutoCad class and the teacher showed us how to convert AutoCad drawings to mastercam

- Q: Metal materials commonly used in the processing methods which

- In addition to the common processing methods, the hot and cold combination molding methods are modern explosion molding, friction welding, rolling, wire cutting, laser surface treatment, high energy ray bombardment, amorphous treatment

- Q: I need to find artists or phootgraphers who used machines in their work, engines and steam engines.

- H. okorder /

- Q: What kind of material is used for processing shafts?

- What material is to look at the specific situation, the general industrial machinery drive shaft is 45 steel, requiring a high point with 40 chromium, but also a good point with 42 chrome molybdenum.

- Q: I need it!!

- try okorder /

- Q: Women: Do you like to operate machinery? Weedeaters? Lawnmowers? Tillers? Tractors? Etc?

- Not really lol - - mowing a lawn is pretty boring - weedeater!! definitely not - the tractor would be the only thing that 'might' interest me :) - I'm a seamstress, I could make you a pair of jeans, that any good lol :))

Send your message to us

Concrete Purline Machine with One Edge Taper

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords