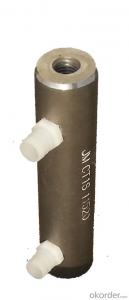

rebar mechanical splicing couplers

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

(1). Mechanical Splicing Technology&Equipment

This type of mechanical splicing technology is a patent of CABR/M.Its principle is cutting

the rebar ribs first before rolling parallel thread on the head of rebar(The two procedures are

finished by a special thread making machine invented by us,please refer to the picture

below),then connecting two rebars with a coupler which has female screw thread.

(2) Technical advantages & Product Features

(1) High-strength of splicing:Meeting the requirements in JGJ107,ACI318, BS8110,

DIN1045, UBC1997, NF A35-020

(2) Excellent anti-fatigue nature:Having passed 2 million times' fatigue experiments.

(3) Good thread form and high precision of screw thread:the splicing quality is stable

and reliable.No fake thread is produced.

(4) Wide range of application:applicable to the same or different diameter

rebars'(12-50mm) connection in any directions and positions.

(5) High-speed construction:The screw thread head can be made before constructing to

ensure the rebars to be connected on site.

(6).Environmental friendly construction procedure:The construction site is safe and

reliable,free from any pollution.

(7) Energy saving:The rated power of the equipment is 3-4Kw only,no need to use

special electric power facilities.

(8) Excellent anti-low-temperature nature:Having passed -40°C low temperature test.

(9) Construction under all weather conditions practicable:not influenced by such

weather conditions as wind,rain or snow.

(10) Manufactured under strict quality standard ISO9001:2000.

(11) Full traceability of material origin and production batch.

- Q: why are men still allowed to operate weaponry and heavy machinery?

- They get licenses for them and there is no law preventing them from doing this? Is there another reason fro why they should not be? I don't understand the question.

- Q: I bought an Oasis Machinery Dust Collector. Any free replacement bags?

- es okorder

- Q: What type of machinery would you consider lawn mowers and weed 'whackers'?

- Could be defined as outdoor power equipment technically.

- Q: Which machinery makes this type of packaging /bags?

- I don't like links.

- Q: I am making a hypothetical business for school and have decided to create a business that makes whey protein powder from the whey left over from the making cheese. I have searched all over the net but I cant find any information on the machinery used in this process. Can anyone help

- nope

- Q: but the problem is that some materials are not available in india and i want to search the any material with same compositions of the requird materials. so is there any website or any book from where i can find that

- Matweb okorder

- Q: I know the basics - clear cut the trees, put explosives in the mountains, blow the mountain up, separate coal from waste, fill up valleys and then plant some grass. What I want to know if more about the machinery used - some sites talk about a quot;dragline,quot; but don't have any more info than quot;it is used in MTRquot; What kind of explosives are used? How do they gather/separate the coal from the mining waste?

- The explosive is a slurry of Diesel fuel and potassium nitrate that is pumped into the drilled holes for surface mining. They use Semtex and variations of it to do underground mining because of how fast the explosion is. As far as separating there is a very small amount of other materials when you are mining coal. It exists in large quantities at a pure rate. There is almost no need to separate anything from the haul.

- Q: why are larger fields needed for machinery such as combine harvesters,tractors and ploughs?

- Efficiency.

- Q: Or do I have to claim my business as a medium size cooperation?

- mr. penis envy, my guess is you would have yourself an illegal medium size corporation . but that is ok, since you'll be illegal you don't have to pay taxes and the mexicans will have jobs so they can send money back to mexico to feed little mexicans. it's a win win situation! but seriously, just remember one thing though: immigrants, like the 45 illegal one's you mention, built this country so that your lazy *** can sit in front of a computer, call yourself 'penis envy' and ask moronic questions to kill time. thanks

- Q: electric digram for desel generator wih 105 kva

- Call or write to the manufacturer.

Send your message to us

rebar mechanical splicing couplers

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords