Rockwool production line 4 Mton Annual Capacity

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.CE/ISO/TUV certificate

2.12 months warranty

3.10 years experience

4.Warranty:12 months

5.Precision:within 1.00mm

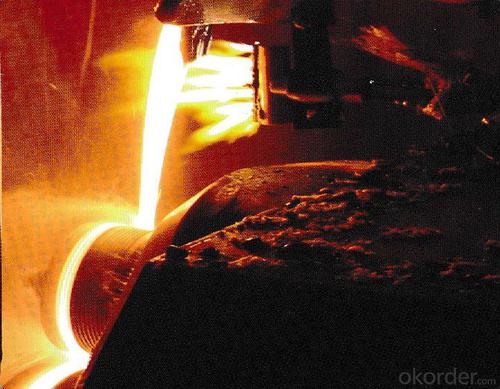

4 Mton Annual Capacity Rockwool production line

Rockwool insulation products are the economical and practical choice. The products are produced from a renewable naturally occurring volcanic rock, saving costs in fuel and energy use.

The products are made from stone wool, a solid rock, to provide stability and durability over the lifetime of a building. The durability of its physical structure means it will keep its dimensions, despite any changes in temperature and humidity. Rockwool’s durable products won’t cause or promote corrosion.

Specification of 4 Mton Annual Capacity Rockwool Production Line

OutPut Capacity: 3-3.2 ton/ hour

Capacity, mt/a | 40000 |

Workshop (L×W), m2 | 100×20 |

Dimension (L×W×H), m3 | 90×15×7 |

Weight, mt | 260 |

Power, kw | 950 |

Main Features of products

- Q: it has for wheels and u can move around int it .... i can not think of its name!! PLEASE HELP =0

- A scissor-lift?

- Q: A. physicalB. intangibleC. tangibleD. transient

- i guess c

- Q: How to choose mechanical parts material ah?

- The performance of the various materials should be very familiar, and then consult the manual to see what general use in the area.

- Q: Retired a piece of machinery that?

- I was on Yahoo for something else, then this question was trending on the sidebar...

- Q: i need help w/ a science question lol....:] help please! thnx! o and also, the 1st question is more important, but if u know this one, it would help too: How is friction a factor in outer space?

- rather some what we do is actual extravagant and likely isn't activities we do interior the destiny as they are going to be called asinine and wasteful. i imagine such issues because the internet will make the great united states of america state out of date, if truth be told its out of date now, any united states of america more suitable than Portugal will probably split into smaller countries. there'll be extra decentralization and emphasis on close by-ness, and we would properly be placed lower back in our gardens for far of what we eat on a on a daily basis foundation, even severe tech indoor all 12 months gardens with tiny robotic pollinators, i imagine some English crew of chaps actual made robotic bees many years in the past. 3-d printers would made stuff out of superior biodegradable plastics derived from cotton or algae. and robotic prostitutes will cater to each and each of the deviants, and if truth be told each body. no longer advantageous what human beings will actual do, yet those issues would replace the way we artwork. there is resistance in this regard, although that is idea that folk would take care of to get a lot of what we deem college preparation from homestead, you may already pay interest to three lectures on podcast.

- Q: I sold $30,000 in business assets(machinery,equipment)this year, how would I claim that on my taxes. would it be considered quot;other incomequot; or quot;capital gainquot;?

- I am sure you have depreciated those assets over the years since you put in service, so what you do is: You need dispose them, which means enter sale date, sale price, sales expenses (if you have any) and adjusted basis (cost - accumulated depreciation- current year's depreciation= usually computer does this calculation for you) then you will know if you have gain or loss. You need do this by accessing your depreciation worksheet for each asset. If you haven't depreciated them for over the years, you probably should report those on the Form 4797(not capital assets form Schedule D)- sale of business assets. OK?

- Q: would these include non motorized equipment used for processing?

- Baler------ This is pulled by the tractor and used to make bales out of crops like hay. It makes a round bale that is 4'x4' tall. Each bale will feed about 25 cows a day. Combine------ This is used to harvest all kinds of crops. It does more than one thing--like pick and clean the crop. It has a sieve in it to get rid of the crop junk. They even have special ones if the farmer has lots of hills. Chisel Plow----- Plows dig up the soil to get it ready for planting. It will turn over the dirt as it digs. Cotton Picker----This machine picks cotton and puts it into the back. The cab has air conditioning and a cassette player/ radio/ and weather radio. It has a special seat for back support. Mower---- This is pulled by a tractor and mows down grass and low growing things. Row Planter---The containers at the top hold the seeds to be planted. This is pulled across the field that the farmer wants to plant. Row Planter---The containers at the top hold the seeds to be planted. This is pulled across the field that the farmer wants to plant. Seed Drill--- This is pulled by a tractor. It is used to plant grains and vegetable seeds. This can make different kinds of ditches that the seeds go in depending on what kind of soil there is. Sprayer--- This is used if the farmer needs to spray their crops for anything [like bugs]. It has a great cab, or place where the driver sits. The equipment company builds these to make farmers more comfortable while they work. Tractor--- This is one of the most important pieces of equipment that a farmer has. He uses it to pull equipment and crop wagons. The equipment company makes the cabs of these very comfortable, too. The farmer picks the tractor size based on what he wants to pull with it. ()

- Q: Any web site could get free machinery manual?

- actually, okorder /... Cheers nb: please visit my web site

- Q: technical feasibility study for a theme parkabout machineriesand equipment

- How about what it will take a rollercoster that is fun and safe?

- Q: i like to know what will be the cost of pp woven sack machinery for single unit .it also known as circular loom.

- Check okorder /

Send your message to us

Rockwool production line 4 Mton Annual Capacity

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords