Extrusion Concrete Purline Making Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Extrusion Concrete Purline Making Machine

1. Structure of Extrusion Concrete Purline Making Machine:

Extrusion Concrete Purline Making Machine is our special developed products as results of our engineers research, with which 60%steel material will be saved compared with traditional revolving die method .Efficiency can be improved 3 to 5 times compared with conical die method, these machine are easy for operation and convenient for maintenance, products from these machines are in good quality, smooth appearance and accurate in size.

2. Main Features of Extrusion Concrete Purline Making Machine:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

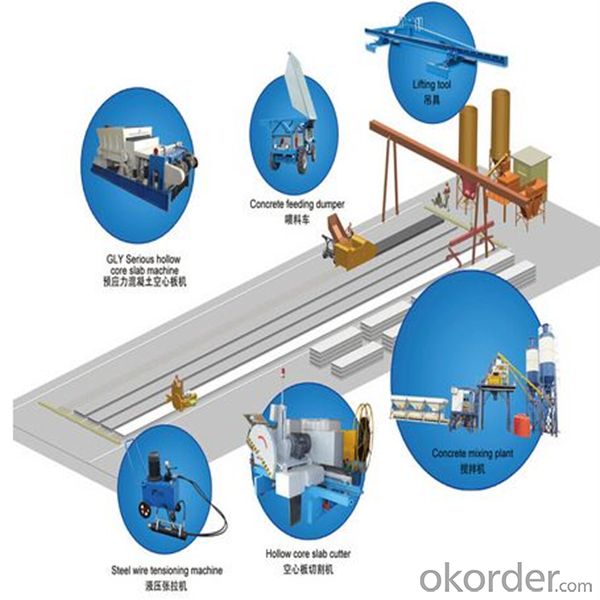

3. Extrusion Concrete Purline Making Machine Images:

4. Extrusion Concrete Purline Making Machine Specification:

Model no. | No. of holes | Dia. | No. and dia. of wires | Electric motor power(kw) | Vibrator Motor Power(kw) | Total Power (kw) | Max. span | Molding Speed(m/min) | Overall dimension (mm) | Weight (kg) |

60X120X140X4 | 1 | 30 | 5/5 | 4 | 1.5 | 5.5 | 3.5 | 1.3-1.5 | 2250×900×850 | 1000 |

60X130X150X4 | 1 | 30 | 6/5 | 4 | 1.5 | 5.5 | 4 | 1.3-1.5 | 2250×900×850 | 1000 |

70X140X160X4 | 1 | 30 | 8/5 | 4 | 1.5 | 5.5 | 4.5 | 1.3-1.5 | 2250×900×850 | 1050 |

70X150X170X2 | 1 | 30 | 8/5 | 3 | 1.5 | 4.5 | 4.7 | 1.3-1.5 | 2250×900×850 | 750 |

60X110X130X4 | 1 | 30 | 6/5 | 4 | 1.5 | 5.5 | 3.5 | 1.3-1.5 | 2250×900×850 | 950 |

Production Line Layout

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. Customers from All Over The World

7. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

8. Why choose us:

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

9. Our Service:

• We supply the technical supporting all the time.

• We supply one year warranty for whole machine.

• We supply free quick wear parts.

• We supply low charge continue maintenance when warranty is expired.

• We supply free training to end-users

- Q: Can you just tell me what you did as a machinery repairman? Where was your first station that you went to? Or where you assigned directly to a ship? Did you ever get stationed at the Norfolk Naval Shipyard? Did you ever go overseas? Were you on the ship more or on shore more? And finally but not least when you were deployed how long were you usually deployed for?i know i have alot of questions but its something im interested in and no one has given me a straight answer. But anything will be greatly appreciated.Thank you for your time and God Bless :-)

- First okorder /

- Q: How does operating machinery under water complicate mining procedures?

- Well it severely limits the type of power source you can use, corrosion of metal parts becomes a major factor, manipulation/positioning of machinery becomes extremely complicated, health and safety is even more of a problem, costs increase exponentially

- Q: ....i should just glue my mouth shut...

- good one . . . i think :)

- Q: I just wanna know how much sea duty will they get and how much shore duty will they get? Is there a possibilty that they can get more shore duty? And yes i know i know when you are in the navy you're going to be on the sea thank you i heard that so many times lol!!!! But any answers will be great!!Thank you all and god bless

- Considering that every ship in the NAVY has machinery on it and that if it breaks down while at sea it has to be repaired and in some cases right then I would say that sea duty is in your future for most of your time in the navy. Shore duty for the Black Boot Rates is there but to get it you are usually a short timer or a lifer soon to get out.

- Q: Such as in terms of construction equipment like a crane, what is the maximum amount of weight that can be lifted by any existing machine?

- A crane's limitation is defined as metre-tonnes, because it is the moment that creates the limitation of the crane lift. A crane does the same amount of work to lift 50 tonnes at 10 metres as it does to lift 100 tonnes at 5 metres. That being said; I believe the largest single lift was perfromed by one of forty-two Lampson Tranis Lift IIs in Corpus Christi TX. The actual load was 1000 tonnes. And this just happens to be a MOBILE unit, on top of everything else!

- Q: How to be the agent of zhengzhou Kefid machinery?

- kefid okorder

- Q: Presented here are selected transactions for Snow Company for 2012.Jan. 1Retired a piece of machinery that was purchased on January 1, 2002. The machine cost $66,300 on that date and had a useful life of 10 years with no salvage value.June 30Sold a computer that was purchased on January 1, 2009. The computer cost $31,200 and had a useful life of 5 years with no salvage value. The computer was sold for $12,480.Dec. 31Discarded a delivery truck that was purchased on January 1, 2007. The truck cost $53,000 and was depreciated based on an 8-year useful life with a $6,300 salvage value.Journalize all entries required on the above dates, including entries to update depreciation, where applicable, on assets disposed of. Snow Company uses straight-line depreciation. (Assume depreciation is up to date as of December 31, 2011.)

- Jan. 1 Retired a piece of machinery that was purchased on January 1, 2002. The machine cost $66,300 on that date and had a useful life of 10 years with no salvage value. After 10 years the machinery is fully depreciated. Dr Accumulated Depreciation--Machinery 66,300 Cr Machinery 66,300 June 30 Sold a computer that was purchased on January 1, 2009. The computer cost $31,200 and had a useful life of 5 years with no salvage value. The computer was sold for $12,480. Six months of depreciation has accumulated since the beginning of the year. 31,200 / 5 x 6/12 = $3,120 to update depreciation Dr Depreciation Expense--Computer 3,120 Cr Accumulated Depreciation--Computer 3,120 31,200 / 5 x 3 1/2 = 21,840 total accumulated depreciation at time of sale Dr Cash 12,480 Dr Accumulated Depreciation--Computer 21,840 Cr Computer 31,200 Cr Gain on Sale of Computer 3,120 Dec. 31 Discarded a delivery truck that was purchased on January 1, 2007. The truck cost $53,000 and was depreciated based on an 8-year useful life with a $6,300 salvage value. (53,000 - 6,300) / 8 = $5,837.50 to update depreciation Dr Depreciation Expense--Truck 5,837.50 Cr Accumulated Depreciation--Truck 5,837.50 5,837.50 x 6 = 35,025 total accumulated depreciation at time of sale Dr Accumulated Depreciation--Truck 35,025 Dr Loss on Disposal 17,975 Cr Truck 53,000

- Q: but the problem is that some materials are not available in india and i want to search the any material with same compositions of the requird materials. so is there any website or any book from where i can find that

- Matweb okorder

- Q: i am looking to go to school for machinery operating like cranes, hyax bull dozers that kind of stuffand i cant find anything in troy new york. I dont know hat i am doing wrong i just recently moved up her. Can anyone help me please? thank you

- Here okorder /

- Q: why on ship machinery's are installed forward-aft & not port starboard?

- It is easier to pick up the frame spacings for structural support running fore/aft as opposed to port/starboard

Send your message to us

Extrusion Concrete Purline Making Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords