Prefabricated Lightweight Concrete Purline Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Prefabricated Lightweight Concrete Purline Machine

1. Structure of Prefabricated Lightweight Concrete Purline Machine:

Prefabricated Lightweight Concrete Purline Machine is our special developed products as results of our engineers research, with which 60%steel material will be saved compared with traditional revolving die method .Efficiency can be improved 3 to 5 times compared with conical die method, these machine are easy for operation and convenient for maintenance, products from these machines are in good quality, smooth appearance and accurate in size.

2. Main Features of Prefabricated Lightweight Concrete Purline Machine:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

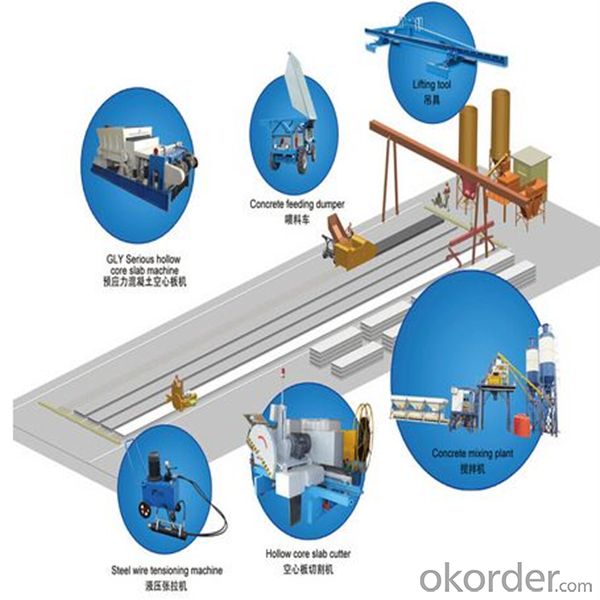

3. Prefabricated Lightweight Concrete Purline Machine Images:

4. Prefabricated Lightweight Concrete Purline Machine Specification:

Model no. | No. of holes | Dia. | No. and dia. of wires | Electric motor power(kw) | Vibrator Motor Power(kw) | Total Power (kw) | Max. span | Molding Speed(m/min) | Overall dimension (mm) | Weight (kg) |

60X120X140X4 | 1 | 30 | 5/5 | 4 | 1.5 | 5.5 | 3.5 | 1.3-1.5 | 2250×900×850 | 1000 |

60X130X150X4 | 1 | 30 | 6/5 | 4 | 1.5 | 5.5 | 4 | 1.3-1.5 | 2250×900×850 | 1000 |

70X140X160X4 | 1 | 30 | 8/5 | 4 | 1.5 | 5.5 | 4.5 | 1.3-1.5 | 2250×900×850 | 1050 |

70X150X170X2 | 1 | 30 | 8/5 | 3 | 1.5 | 4.5 | 4.7 | 1.3-1.5 | 2250×900×850 | 750 |

60X110X130X4 | 1 | 30 | 6/5 | 4 | 1.5 | 5.5 | 3.5 | 1.3-1.5 | 2250×900×850 | 950 |

Production Line Layout

Certificates

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. Customers from All Over The World

7. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

8. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

9. Our Service:

• We supply the technical supporting all the time.

• We supply one year warranty for whole machine.

• We supply free quick wear parts.

• We supply low charge continue maintenance when warranty is expired.

• We supply free training to end-users

- Q: Please include your reference. Thank you.

- From their web site: ?The Association for Computing Machinery was founded as the Eastern Association for Computing Machinery at a meeting at Columbia University in New York on September 15, 1947. Its creation was the logical outgrowth of increasing interest in computers as evidenced by several events, including a January 1947 symposium at Harvard University on large-scale digital calculating machinery; the six-meeting series in 1946-47 on digital and analog computing machinery conducted by the New York Chapter of the American Institute of Electrical Engineers; and the six-meeting series in March and April 1947, on electronic computing machinery conducted by the Department of Electrical Engineering at Massachusetts Institute of Technology. In January 1948, the word Eastern was dropped from the name of the Association. In September 1949, a constitution was instituted by membership approval.

- Q: if not how much would you pay for one if i did it (NOT)

- There okorder /... may be an example

- Q: What was the last thing that prevented you from driving or operating heavy machinery?

- All the damn hippies surrounding it trying to stop me from taking down those trees because squirrels live there. I was about to run the over, the hippies not the squirrels, but the boss said no.

- Q: Is machinery still being built?

- yes it is

- Q: Where can I sell used printing machinery and equipment online?

- OKorder

- Q: Is there any difference between the two words? I want to name a company's name, the product is machines.By the way, what about packing and packaging? are the different. The machine is mainly packaging facilities, how can i name the company's name?

- Machine is just a singe machine but when many similar or different machines are grouped to perform a specific task, it is now referred to as MACHINERY.

- Q: what is machinery?and its uses.?

- Machinery is a series of components working together to accomplish a particular task. They can be crude, simple machines such as a block and tackle or very complex like a CNC Machine or a monster earth moving crane. Most machinery is used in production or manufacturing.However machinery is als o used to move a ship through the water, dig a tunnel or mine shaft, drill for oil, make a baseball bat, make candy etc. The uses are endless.

- Q: What kind of material is used for processing shafts?

- What material is to look at the specific situation, the general industrial machinery drive shaft is 45 steel, requiring a high point with 40 chromium, but also a good point with 42 chrome molybdenum.

- Q: Reconditions will do, will need some for places with dire needs

- The okorder /

- Q: I have a stepson who has a keen interest in combine harvesters and I had the idea to take him to see them being built at a farm machinery manufacturer somewhere, but have no idea who to enquire for about this and whether they would allow a factory tour to see these machines being put together. Does anyone have information that could be of help to me to arrange this for him as a surprise day out? Thanks.

- John okorder /

Send your message to us

Prefabricated Lightweight Concrete Purline Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords