Vertical Concrete Purline Molding Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Vertical Concrete Purline Molding Machine

1. Structure of Vertical Concrete Purline Molding Machine:

Vertical Concrete Purline Molding Machine is our special developed products as results of our engineers research, with which 60%steel material will be saved compared with traditional revolving die method .Efficiency can be improved 3 to 5 times compared with conical die method, these machine are easy for operation and convenient for maintenance, products from these machines are in good quality, smooth appearance and accurate in size.

2. Main Features of Vertical Concrete Purline Molding Machine:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

3. Vertical Concrete Purline Molding Machine Images:

4. Prefabricated Concrete Purline Compression Molding Machine Specification:

Product name | Type | Productivity | Hole number |

Concrete purline machine | 60*120*140* | 1.3-1.5m/min | 4 |

Concrete purline machine | 60*130*150*4 | 1.3-1.5m/min | 4 |

Concrete purline machine | 60*140*160*4 | 1.3-1.5m/min | 4 |

Concrete purline machine | 70*150*170*2 | 1.3-1.5m/min | 2 |

Concrete purline machine | 80*160*180*2 | 1.3-1.5m/min | 2 |

Concrete purline machine | 60*110*130*4 | 1.3-1.5m/min | 4 |

Model no. | No. of holes | Dia. | No. and dia. of wires | Electric motor power(kw) | Vibrator Motor Power(kw) | Total Power (kw) | Max. span | Molding Speed(m/min) | Overall dimension (mm) | Weight (kg) |

60X120X140X4 | 1 | 30 | 5/5 | 4 | 1.5 | 5.5 | 3.5 | 1.3-1.5 | 2250×900×850 | 1000 |

60X130X150X4 | 1 | 30 | 6/5 | 4 | 1.5 | 5.5 | 4 | 1.3-1.5 | 2250×900×850 | 1000 |

70X140X160X4 | 1 | 30 | 8/5 | 4 | 1.5 | 5.5 | 4.5 | 1.3-1.5 | 2250×900×850 | 1050 |

70X150X170X2 | 1 | 30 | 8/5 | 3 | 1.5 | 4.5 | 4.7 | 1.3-1.5 | 2250×900×850 | 750 |

60X110X130X4 | 1 | 30 | 6/5 | 4 | 1.5 | 5.5 | 3.5 | 1.3-1.5 | 2250×900×850 | 950 |

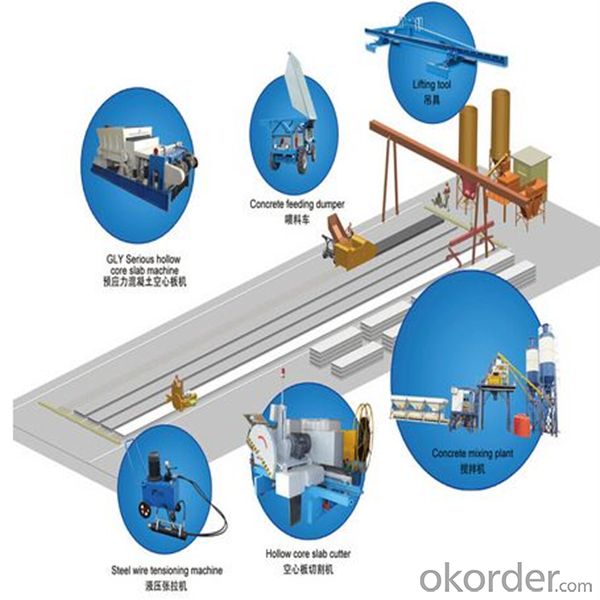

Production Line Layout

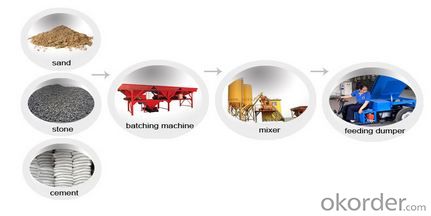

Production Process

Rebar tensioning

Raw materials preparing

Molding

Certificates

5. Customers from All Over The World

6. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

7. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

- Q: I'm a vegetarian who doesn't eat fish and I was just wondering what this means.

- That notice is mostly for people who have allergies. It means that there is a chance that there are trace amounts of the ingredient listed in the product. While the company does not deliberately add the ingredient to the product, there might be lingering particles on the machinery, so if you have severe allergies, you should skip it. If buying from vegetarian-only companies is important to you or you have an allergy, skip the product. Otherwise, you can probably have it.

- Q: Is there any common pattern between the two?While several ultra-Islamist countries have draconian laws to punish everyone who slanders god, CCP is known to punish everyone who slanders the Chinese Communist Party. CCP often resorts to informal detentions, punishments and disappearances which are completely outside the law, and so offer the government deniability and the victim no protection whatsoever.Do the Chinese people find any commonality between the Blasphemy Laws practiced in Islamist countries and the draconian policies of CCP?

- Have you also noticed that these religious fanatics use God to justify their actions rather than the laws that benefit the people? It is similar in that China uses the welfare of the state rather than a god to get to the same end, and that is domination of the masses.

- Q: Retired a piece of machinery that?

- Presented below are selected transactions at Ingles Company for 2008.Jan. 1Retired a piece of machinery that was purchased on January 1, 1998. The machine cost $62,000 on that date. It had a useful life of 10 years with no salvage value.June 30Sold a computer that was purchased on January 1, 2005. The computer cost $40,000. It had a useful life of 5 years with no salvage value. The computer was sold for $14,000.Dec. 31Discarded a delivery truck that was purchased on January 1, 2004. The truck cost $39,000. It was depreciated based on a 6-year useful life with a $3,000 salvage value.Journalize all entries required on the above dates, including entries to update depreciation, where applicable, on assets disposed of. Ingles Company uses straight-line depreciation. (Assume depreciation is up to date as of December 31, 2007.) (List multiple debit/credit entries in descending order of amount.)

- Q: I am making a hypothetical business for school and have decided to create a business that makes whey protein powder from the whey left over from the making cheese. I have searched all over the net but I cant find any information on the machinery used in this process. Can anyone help

- nope

- Q: I'm not very fond of walking on the treadmill for half an hour or going to the gym and using those big, scary machines. O.oBut I really want to lose weight and stay healthy, just without all that metal tearing me apart. What kinds of exercises are best for losing weight without the use of machines?

- The best kind of exercises are the one's you enjoy doing, that way you will be consistent with your exercising routine. Here are some examples - Running, brisk walking, walking up hills/stairs, sprinting, skipping (all you need is a cheap skipping rope), dancing, squats, lunges, burpees, the plank, crunches, push-ups, tricep dips etc etc

- Q: i want to sell a candle an unused candle extruder i bought couple of years ago, which internet sites can help me do that?

- Goto okorder

- Q: plz help! its my homework :P ugh. thanks guys xD

- The Oxford American Writer's Thesaurus does not mention any antonyms. The opposite of a machine might be human labor. Did you mean synonym? (meaning similar) ... If so, apparatus ,hardware, gear, mechanism, gadgetry, tool, engine

- Q: I want to be an engineer who works with microchips and things like that. Are there any small projects and things which I could do at home (spending less than $100-200) just to get a feel for things?

- Machinery and IC's is a strange combination. As the other person said, first learn the basics, such as ohms law, resistance capacitance and inductance, and then simple circuits. You need all of that before you can even think of an IC.

- Q: Hello, our family business is rather kind of in need, to start producing our cake mixes in larger quantities.I ahve not been able to find a manufacturer that sells this amchinery. Please ask any further questions.God Bless

- you okorder /

- Q: Why won't the machinery implement an optic pie?

- Cherry pie.... is very difficult to find.

Send your message to us

Vertical Concrete Purline Molding Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords