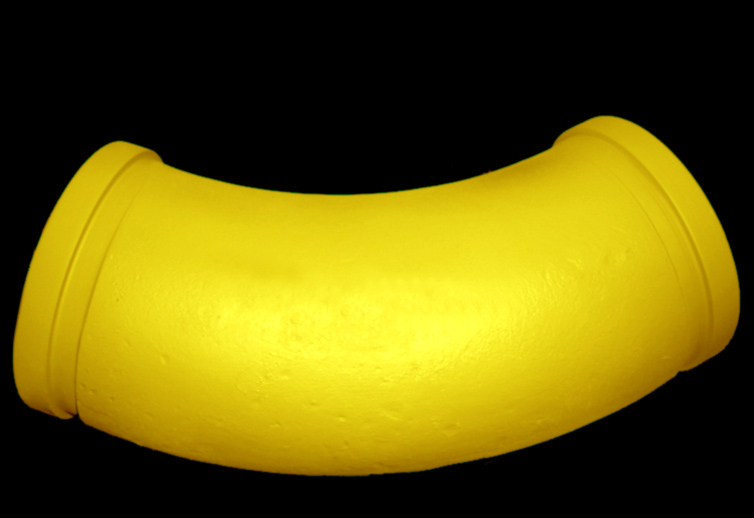

Concrete Pump Truck Parts Elbow Bend DN125 R180 45DGR 148MM Mn13-4 Casting

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: Are there any cost-effective alternatives to original concrete pump spare parts?

- Indeed, there exist cost-effective alternatives to the original spare parts for concrete pumps. One possibility is to contemplate acquiring aftermarket parts, which are frequently manufactured by third-party producers. These components are engineered to meet identical specifications and criteria as the original parts, yet they are commonly obtainable at a reduced price. Another avenue to explore is the acquisition of used or refurbished parts. These parts have previously been employed but have been refurbished to function flawlessly, presenting a more economical substitute for new parts. Nevertheless, it is crucial to verify that these alternatives are obtained from trustworthy suppliers to guarantee quality and compatibility with the particular model of your concrete pump.

- Q: How does a hydraulic oil cooler maintain optimal temperature in a concrete pump?

- A hydraulic oil cooler plays a crucial role in maintaining optimal temperature in a concrete pump by effectively dissipating heat generated during the hydraulic system's operation. As the hydraulic system of a concrete pump is continuously subjected to high pressure and heavy loads, the oil within the system tends to heat up rapidly. If the oil temperature exceeds the recommended range, it can lead to a decrease in overall system efficiency, increased wear and tear of components, and potential system failure. To prevent these issues, a hydraulic oil cooler is installed in the concrete pump. It works by utilizing a heat exchanger that transfers the excessive heat from the hydraulic oil to the surrounding air or another cooling medium, such as water or a refrigerant. This heat exchange process helps to lower the temperature of the hydraulic oil, maintaining it within the optimal operating range. The hydraulic oil cooler typically consists of a series of fins or tubes through which the hot oil flows. These fins or tubes increase the surface area of contact between the oil and the cooling medium, allowing for efficient heat transfer. Additionally, a fan or a pump may be used to enhance the airflow or flow of the cooling medium, further improving the cooling process. By maintaining the hydraulic oil at an optimal temperature, the hydraulic oil cooler ensures that the concrete pump operates at its peak performance. This not only increases the overall efficiency and productivity of the pump but also prolongs the lifespan of critical components. Moreover, by preventing overheating, the hydraulic oil cooler helps to minimize the risk of costly and unexpected downtime due to system failure. In conclusion, a hydraulic oil cooler is an essential component in a concrete pump that maintains optimal temperature by dissipating excessive heat from the hydraulic oil. By effectively cooling the oil, it ensures the smooth operation, efficiency, and longevity of the hydraulic system, ultimately contributing to the overall productivity and reliability of the concrete pump.

- Q: How can one determine the correct size and dimensions of concrete pump spare parts?

- To determine the correct size and dimensions of concrete pump spare parts, one should refer to the manufacturer's specifications and documentation. These documents typically provide detailed information about the specific measurements and dimensions required for each spare part. Additionally, consulting with experts or professionals in the field can also help in identifying the correct size and dimensions based on the specific make and model of the concrete pump.

- Q: Is the main pump of the concrete pump electric control or hydraulic control?

- The main pump behind the oil pump to provide the size of the oil with the greater the current the higher the higher the higher the displacement,

- Q: Can concrete pump spare parts be purchased online?

- Yes, concrete pump spare parts can be purchased online. There are numerous websites and online marketplaces that offer a wide range of concrete pump spare parts for purchase, making it convenient for customers to find and order the specific parts they need for their equipment.

- Q: How can the concrete pump pipe be cleaned?

- Secure the cover at the end of the pipe so that the concrete does not hurt.

- Q: How often should the concrete pump cylinder be replaced?

- The replacement frequency of the concrete pump cylinder relies on several factors, including usage, concrete quality, and pump maintenance. With proper care and regular servicing, a concrete pump cylinder can last for many years. However, it is advisable to regularly inspect the cylinder for wear and tear and replace it immediately if any damage or deterioration is noticed. It is wise to take a proactive approach and replace the cylinder before it completely fails to prevent accidents or disruptions during pumping. Ultimately, consulting the manufacturer's guidelines and recommendations for the specific make and model of the concrete pump cylinder is the best course of action.

- Q: Can concrete pump spare parts be ordered in bulk quantities for future use?

- Yes, concrete pump spare parts can definitely be ordered in bulk quantities for future use. Many suppliers and manufacturers offer bulk ordering options to cater to the needs of contractors and construction companies. Ordering in bulk can provide several advantages such as cost savings, convenience, and ensuring a consistent supply of spare parts for maintenance and repairs. It is always recommended to have spare parts readily available to minimize downtime and maximize the efficiency and performance of concrete pumps.

- Q: Do concrete pump spare parts come with a warranty?

- Yes, concrete pump spare parts typically come with a warranty. The specific duration and coverage of the warranty may vary depending on the manufacturer and supplier. It is advisable to check the product specifications or consult with the supplier to understand the warranty terms for concrete pump spare parts.

- Q: What is the function of a concrete pump hydraulic motor?

- The concrete pump hydraulic motor serves the purpose of supplying the essential power and force needed for the operation of the concrete pump. Its responsibility lies in transforming hydraulic energy into mechanical energy, thereby enabling the pump to function with efficiency and effectiveness. By propelling the pumping mechanism, it allows the concrete to be transported through the pipeline and delivered to the desired destination. Additionally, the hydraulic motor governs the pump's speed and direction, facilitating accurate placement of the concrete. In conclusion, the concrete pump hydraulic motor plays a vital role in guaranteeing the seamless operation and triumphant delivery of concrete in construction endeavors.

Send your message to us

Concrete Pump Truck Parts Elbow Bend DN125 R180 45DGR 148MM Mn13-4 Casting

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords