Posa Geomembrane Compound Geomembrane Composite with Two Geotextiles and One Geomembrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Geomembranes are generally considered to be made from continuous, highly impermeable, extruded flexible sheets of either HDPE (High Density Polyethylene) or LDPE (Low Density Polyethylene). However, it is also possible to tightly weave small tape fibres of these polymers so as to achieve (either directly or by subsequent treatment) an impermeable membrane. Predominantly, the continuous extruded sheets are used for water containment or waste disposal linings. These inevitably involve the lining of soil slopes and, in order to increase the frictional characteristics of the membranes, so as to resist sliding, one or both sides of geomembranes can be provided with roughened or raised profile surfaces.

Applications:

Geomembranes have a very low coefficient of permeability - much lower than most clays and natural soils. HDPE, in particular, is highly resistant to any form of chemical or biological attack. It is also very resistant to U.V. degradation. Many geomembranes are so inert that they cannot be glued together - the chemical reactions of adhesives do not work on them - they have to be welded together by heat. Their inert nature and long life characteristics make HDPE geomembranes ideal to act as liners for liquid chemical reservoirs, fresh-water reservoirs, animal waste containers, basal linings and top capping layers for waste disposal sites. During installation, HDPE geomembrane edges are sealed to one another with a double heat welded joint. The gap between the two welds is checked for leakage using an air pressure test. Many users consider that HDPE is the ideal material for the purpose of lining water and waste disposal sites because of its proven long term stability and resistance to chemical attack, but in addition to HDPE, there is LDPE, for less demanding applications such as fresh water retention and a membrane reinforced with a polyester reinforcing fabric for use where higher in-plane stresses have to be absorbed.

No. | Item | Test Value | |||||||

0.75mm | 1.0 mm | 1.25 mm | 1.5 mm | 1.8mm | 2.0mm | 2.5 mm | 3.0mm | ||

1 | Minimum Density(g/cm³) | 0.94 | |||||||

2 | Strength at yield,N/mm | 11 | 15 | 18 | 23 | 27 | 30 | 38 | 45 |

3 | Strength at break ,N/mm | 21 | 28 | 33 | 43 | 51 | 57 | 71 | 85 |

4 | Elongation at yield,% | 13 | |||||||

5 | Elongation at break,% | 700min | |||||||

6 | Tear Resistance N | 93 | 125 | 156 | 187 | 219 | 249 | 311 | 373 |

7 | Puncture Resistance N | 263 | 352 | 440 | 530 | 618 | 703 | 881 | 1059 |

8 | Stress Crack Resistance, hrs | 400 | |||||||

9 | Carbon Black Content, % | 2.0-3.0 | |||||||

Carbon Black Dispersion | 1 or 2 | ||||||||

10 | Standard OTI Min | 100 | |||||||

High Pressure OTI Min | 400 | ||||||||

11 | Impact Cold Crack at -70°C | Pass | |||||||

12 | Water vapor permeability (g.cm/cm2 .s.Pa) | ≤1.0×10-13 | |||||||

13 | Dimensional Stability (%) | ±2 | |||||||

FAQ

How about the delivery time?Lead time since receipt of 30% T/T deposit payment: 3 weeks.(Samples will be prepared within 3 days.)

2.What's are the MOQ?Generally speaking, the MOQ is one container, but we can provide you samples for quality inspection.

3. Do you charge for the samples?Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

4. Can you produce according to customers' design?Sure, we are professional manufacturer, OEM and ODM are both welcome.

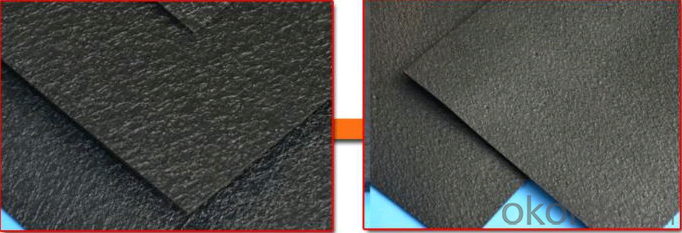

- Q: The difference between the double rough surface soil and the ordinary soil?

- Ordinary geomembrane generally refers to both sides of smooth rough double lines of smooth geomembrane the national standard GB GB type type two and construction standards (equivalent to American Standard) of 0.2-2.0mm thickness between the double textured geomembrane refers to both sides between the rough texture of geomembrane of its national standard index only like the thickness of urban construction 1.0-2.0mm

- Q: What is electrothermal?film floor?

- Low temperature radiant electrothermal film heating system provides heat in the form of far infrared heat with electricity as energy, and pure resistance as heating element. It is made up of polyester film, conductive silver paste, conductive carbon paste and metal carrier.

- Q: What's the technical standards of geomembrane?

- The national standards of geomembrane is GB / T17642-2008. Geomembrane 1. longitudinal and transverse breaking strength. 2. Vertical and horizontal elongation corresponding to the standard strength. 3. CBR bursting strength 4. 5 vertical and horizontal tearing strength. 5, hydrostatic pressure resistance. 6. peel strength. 7. vertical penetration index. 8, width deviation, the above technical requirements that confirm to the national standard are national standard geomembrane.

- Q: How to purchase geomembrane?

- warp-wise tearing?strength, warp-wise elongation?at?break, puncturing strength, broadwise breaking strength, film material thickness, CBR bursting?strength, unit area quality inspection, permeability?coefficient, broadwise tearing?strength, broadwise elongation?at?break, warp-wise breaking strength.

- Q: What kind of membrane should be coated on optical coating glass?

- Polarizing film coated glass: coated glass is the glass which has coated with a layer or several layers of metal, alloy or metallic compound thin?film on the surface so as to change the optical properties of glass and satisfy certain requirements. According to different characteristics of products, coated glass can be divided into: heat reflecting glass, low emissivity glass (low-E), conductive film glass, etc

- Q: Can geomembranes be used for landfill capping?

- Yes, geomembranes can be used for landfill capping. They are often used as a barrier to prevent the infiltration of rainwater and the escape of gases from the landfill, providing a reliable and effective solution for capping landfills.

- Q: Can geomembranes be used in sludge dewatering applications?

- Yes, geomembranes can be used in sludge dewatering applications. Geomembranes are impermeable liners that can be placed over sludge beds to prevent water from seeping out during the dewatering process. This helps to concentrate the sludge and remove excess moisture, making it easier to dispose of or further process the sludge.

- Q: High density polyethylene root-resistant geomembrane

- High density polyvinyl chloride root puncture resistant geomembrane, aslo called high density PVC root resistant membrane, is a kind of geomembrane which has good seepage-proof effect and good resistance to puncture as well. High density PVC root resistant membrane, with good flexibility and puncture resistance, can be used in a variety of complex construction environment. The width of common High density PVC root resistant membrane in current market is 2m. You can use dedicated welding machine when paving a large area of high density PVC root resistant membrane. Besides, the high density polyethylene root puncture resistant geomembrane in market is also called HDPE root resistant membrane which has better anti-seepage effect, anti-puncture ability and longer service life than High density polyvinyl chloride root puncture resistant geomembrane. It is also cheaper than High density polyvinyl chloride root puncture resistant geomembrane so it can completely replace High density polyvinyl chloride root puncture resistant geomembrane. The width of high density polyethylene root acupuncture resistant geomembrane in current market is 8m, which the common width is 6m. Compared with High density polyvinyl chloride root puncture resistant geomembrane, it can reduce welding cost in construction greatly.

- Q: How is the power amplifier tone quality of thick membrane?

- Thick power amplifier tone quality is very good. I think it can protect ears. Thick membrane refers to a film layer from few microns to tens of microns formed through printing sintering technology on the substrate. Materials that makes this film layer is called thick membrane materials.

- Q: Are geomembranes resistant to oil and grease?

- Yes, geomembranes are generally resistant to oil and grease. They are designed to have excellent chemical resistance, including resistance to various oils and greases.

Send your message to us

Posa Geomembrane Compound Geomembrane Composite with Two Geotextiles and One Geomembrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords