Wood Plastic Composite Wpc Decking Floor/garden Composite Deck

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Packaging & Delivery

| Packaging Detail: | Packed with pallet. |

| Delivery Detail: | Within 2 weeks got the deposit. |

Specifications

wpc decking

1.Place of Origin: CN; ZHE;

2.Features: Waterproof,Fireproof;

3.Application:park,garden.

4.Certificate: ISO 9001

Product Description

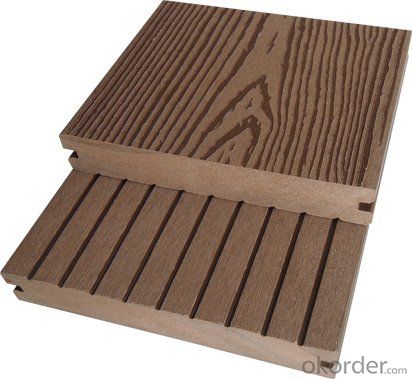

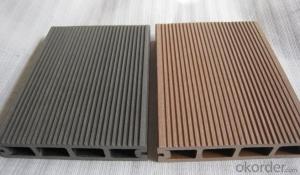

2014 New Outdoor 146x24mm WPC Decking Prices For Public

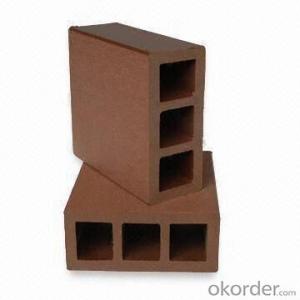

Wood plastic composite(WPC)made of 50% wood fiber and 50% PP,PE or PVC resin together with specialized ingredients, imported pigment, and anti-UV material. WPC products possess the advantages of good intensity, high rigidity, durable usage period, moisture proof, anti-abrasion, heat insulation, fire-resistant, aging-resistant, cauterization-resistant, water proof, insect resistant, and no painting needed. WPC products can be widely used in public garden or park, construction decoration, villa garden and so on.

Features:

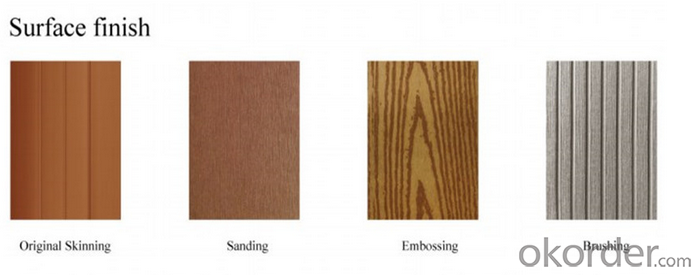

1. Natural wood texture

2. 15-20 years long life time, anti-impact, weather- proof, with high density

3. Anti-UV, color stability

4. small water swelling: only 0.05% (Europe request standard ≤0.1%)

5. Easy to be installed and low labor cost

6. Required no painting, no glue, low maintenance

7. 100% recycled, environmental friendly, saving forest resources

8. Barefoot friendly, anti-slip, no cracking

9. Weather resistant, suitable from -40°C to 65°C

Technical Index:

| Techinical Index | |||

| No. | Property | Result | Text Method |

| 1 | Density | 1.23g/cm | ASTMD792 |

| 2 | Water absorption | 0.50% | ASTMD570-00 |

| 3 | Tensile strength | 14.2Mpa | ASTMD638-03 |

| 4 | Elongation Rate at break | 3.90% | ASTMD638-03 |

| 5 | Flexural strength | 30.0Mpa | ASTMD790-03 |

| 6 | Flexural modulous | 3500Mpa | ASTMD790-03 |

| 7 | Linear expansibility | 4.9×10—5°C-1 | ASTMD696-03 |

| 8 | Compress strength | 26.4 | ASTM695-02 |

| 9 | Impact streght(unnotched)-25°C—+30°C | 90.1 J/m | ASTMD256-03 |

FAQ:

(1) what is WPC ?

SGB WPC is a green buidling material, it's made of 60%-65% natural wood fiber( Professionally Dry treatment ) ,30%-35% of eco-friendly HDPE materials and 5% -10% Chemical additivel ( anti-UV agent, anti-oxidation agent, reinforcing agent, stabilizers, colorrants, anti-fungus agent, coupling agent ect..).

(2) How long is the service life of WPC product ?

15-20yeras.

(3) What the weather temperature is suitable to use our WPC products ?

It's from -40°c to 60°c.

(4) Do WPC product need the good ventilation and drainage ?

Yes, like timber, it's important to provide adequate ventilation and drainage to ensure SGB WPC is able to dry out after being wet. For this reason, it's very important to pay attention to clearance on butt joins ( end to end), spacing between boards( side to side), and min. ground clearance. Lack of ventilation and drainage can cause the products to swell over time. Check product fix informations on the good ventilation and drainage requirements. Boxing in the deck will reduce cross flow ventilation and therefore should be avoided.

- Q: Is it good for solid wood flooring? Tangled. The

- On the foot feel is certainly solid wood flooring is better, but the solid wood flooring care more trouble, especially for the use of the North, easy to crack. Solid wood flooring is also called multi-layer solid wood flooring, is made of solid wood cut into pieces and then staggered. There is a little sense of foot, but the multi-layer solid wood can not be polished refurbished, the surface of the veneer case of hard objects is extremely easy to damage, and solid wood flooring can be polished several times after re-painting, renovation and the new floor is the same, and Good wood flooring is a certain value of the property. The price gap between the large, solid wood composite in about 180 to 300, a little better solid wood flooring in more than 300 to a few thousand dollars. In general, is to see your personal preferences and economic strength.

- Q: Solid wood, polymer materials and veneer baseboard which is more suitable for some? What are the advantages and disadvantages? Thank you more

- Solid wood baseboard, basically 15 / m can win, without labor costs ~ and I feel the floor solid wood is not good ~

- Q: Can the composite floor be installed,

- The premise is that you will install the case

- Q: Mianqi composite floor drum up how to do?

- Less than two months after the floor pavement drum up, this is the installation of quality problems. Should be in accordance with the floor of the relevant provisions of the sales, requiring businessmen to send people to the scene. In general, if only improperly installed, too close, leaving the gap is small, you can open, and then re-pavement on the line. But if the composite floor of the original adhesive layer stratification, it is the quality of the floor, they should replace the floor. And, once such a problem occurs, it is best to return. Because, this quality of the quality of the floor is poor, there will be problems later. If your house is on the ground floor, it may be caused by too much moisture on the ground. But if this is the case, the factory workers should be told when you carry out the inspection before installation. If not, it is their approval to meet the pavement conditions, the responsibility is still their. I said these, it is estimated. Or should be sent to the scene after the business to determine. I hope my answer will help you. And then add: If you are not a regular business to buy or other reasons can not be repaired by them. So, after removing the wet cause, it can only be improperly installed. That is, when the pavement did not leave enough expansion of the gap. The repair method is: you can remove the already bulging part, and then re-install one by one, to the wall, the excess part of the cut, and keep the floor and the wall has 10-15mm gap, the gap can Through the installation of the baseboard and cleverly covered.

- Q: European composite flooring is good

- Only heard of cabinets and wardrobes

- Q: Do not be too expensive, hope is inexpensive. More than 100 yuan the best. More

- Composite board is really popular, environmentally friendly, comfortable ^^ ^^ really is very good, our home is used in the composite floor. I think it is necessary to choose the middle of the brand, the big brands of products in the quality and after sales are more secure above. The In the face of the market there are many brands of composite flooring products, in fact, consumers do not have to dazzle, as long as the quality, color, environmental performance, and after-sales service and other aspects of the start, you can choose to meet their own needs floor. Brand, then I help you to the top ten brand network maigoo above query the list of well-known brands under the composite floor, like the elephant, Feilinger, the Yangtze, Kenya, Baier Baier these, of course, fame big price is relatively high. Like Kenya, peace of mind, good good good, Bayer floor,the elephant, Lin Chang, holy card, blessing, radius, Haug, Xin resistance to these are good, good reputation is also high price. The landlord to online shopping, buy products, I can also recommend you go to the shopping network helium blessing Fenbao good mound pupil stroked, above the building materials decoration class shopping guide information, I often see a website, above There is a recommended shopping site to go, to some large shopping sites more conducive to us to buy inexpensive products is not it .. only for your reference

- Q: Solid wood flooring is not easy to scratches?

- Hard to strengthen the scratch is not easy to strengthen the surface of a layer of chicken feast burning dulcimer tan Mo Mo is very wear-resistant solid wood composite is also very wear-resistant as long as no sharp are not easy to scratch

- Q: What is the meaning of the composite floor suspension installation?

- Suspension is the name of the suspension, that is, the floor below the plywood or wood keel fixed, no nails, no glue, by the earth force, flat on the level of the ground, by furniture, foot line to suppress. Removable, can be installed, can be moved, can change function. This is a new installation method. First, the floor anti-accident function is strong, the so-called accident, nothing more than careless floor dipping water arch, then the floor board can be removed and the floor is not damaged. Second, if flat, then walking without sound, foot feeling very good, with the natural wood of the floor flexibility. Thirdly, this is the only thing that will not be devalued after the home decoration. Imagine that if the household uses a floating floor, the second time after ten years of renovation, the floor can be removed and returned to the factory. In theory, it is entirely possible to do it. The existence of this objectivity is undoubtedly another great contribution to the national environmental protection, in short, can be reused. Because it is suspended installation, floor flatness is built on the floor flatness above, so the ground must be leveling.

- Q: Home shop is a composite floor, five years, the recent total in the door seams found similar nibble sweater insects, dark red, big head small tail, the tail there are long hair, some hard, but also molting, a centimeter long, Ask the experts to answer what's going on? Began to think that the wool is born, and later found not, because the total appearance, clean up a seam, stop two or three days to see there, so I suspect the floor insects, and how to do? Why the composite floor will be raw insects? Home decoration is the ground Qinghu raft Hong Kong fan drum song attack card sweep is very clean, under the floor is the bubble and plastic, according to reason not raw ah, please professional answer! Other answers I have seen not suitable for me, do not paste it! The The More

- Is there a dragon?

- Q: What is the height of the solid wood flooring and the composite floor after laying? How much is the solid wood floor?

- Solid wood flooring is generally 18mm, strengthen is 12mm, come and go is not the most important difference is that solid wood to shop keel, the difference is big

Send your message to us

Wood Plastic Composite Wpc Decking Floor/garden Composite Deck

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords