Low Price Calcium Silicate Board With High Quality

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

(Raw materials: pure quartz powder, quick lime, calcium silicate, plant fiber and many fined mineral stuffing including dispersant and additive) into a wet sheet and then through high temperature and high pressure autoclave for more than 10 hours by advanced technology. That it will compose a special calcium silicate board. There is no asbestos, brucite and meerschaum in the raw materials and the formulations at all.

It can be applied not only in the interior use but also in the outdoor walls. It has low water absorption rate and high impact resistant ability. These advantages make it suitable for any purposes of applications.

Product Applications:

1) Old and new building curtain walls, exterior walls and other outdoor systems

2) European and American styles of architecture and high-end villa roof

3) Indoor hall, office, building facade and podium

4) Kitchen, bathroom, bathrooms, changing rooms and other damp places

5) Subway stations, tunnels and underground works

6) Interior wall decoration system

7) High quality requirements of the ceiling

8) Environmental requirements, particularly Germany occasions

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

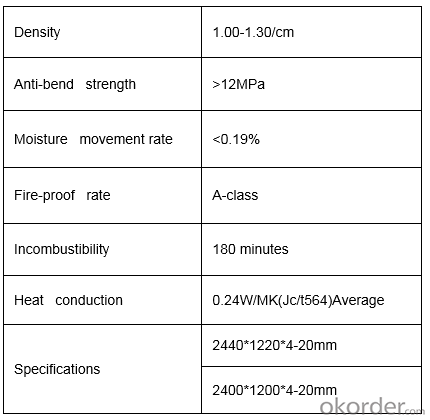

Main Product Features:

100% asbestos-free

Product composition: Portland cement, highly pure quartz sand, cellulose fiber

Density: 1.1-1.4 g/cm3

Water absorption: ≤30%

Moisture interference degree: 0.27mm

Moisture content: ≤10%

Swelling: ≤0.25%

Dry shrinkage rate: 0.5%

Impact resistance: ≥2.0 KJ/m2

Flexural resistance: ≥12 KJ/m2

Thermal conductivity: ≤0.2 W(M.K)

Screw-pull force: ≥75 N/mm

Frost resistance: After 25 freeze-thaw cycles without rupture and layer phenomena.

Product Specifications:

FAQ:

1:.How can I get your prompt quotation?

A: we can give you reply with quotation quickly if you kindly send the inquiry with following factors: working temperature, bulk density, dimension (length*width*thickness), and quantity.

2.What's the MOQ of the order?

No limit, we can offer the best suggestions and solutions according to your condition.

3. Which payment terms can you accept?

T/T,LC,Western Union,moneygram are available for us.

4. After an order is placed, when to deliver?

15-25days after confirming the order.

5. Does your company accept customization?

We accept OEM service.

6. How to solve the quality problems?

If the products don’t conform to customer’s samples or have quality problems, our company will be responsible to make compensation for it based on enough evidence.

Images:

- Q: The difference between calcium silicate board and plywood

- 9MM the following calcium silicate board is a fire board, 9mm or more called fire board. So now many of the domestic decoration with calcium silicate board, and the corresponding aluminum-plastic plate, gypsum board market has shrunk.

- Q: Ceiling with gypsum board or calcium silicate board?

- The shape of the ceiling less With calcium silicate board. Hardness. Waterproof and waterproof. Not easily deformed. Fire performance is better. 2 are not much price.

- Q: Door head decoration, outside the aluminum-plastic plate which can be used calcium silicate board?

- Calcium silicate board is gypsum board, outside the sticky aluminum plastic plate if it is not very heavy, then there is no problem, which is certainly a reinforced keel structure, so do not worry about the problem

- Q: How to distinguish between the color of calcium silicate board is good or bad

- Color distinction Calcium silicate board is good or bad: Direct visual observation to identify: If the hands of a calcium silicate board of the sample, then look directly at its side, to see the side is not a lot of small white spots, those white spots that is asbestos.

- Q: What is the amount of tropicin in the calcium silicate board? Or how to define? What is the effect of the content on the quality of calcium silicate board?

- This question is not a direct answer. The toe mullite is mainly composed of cement and quartz sand at high temperature and high pressure, produced in the autoclave. Of course, is a high point, increase the stability and strength of calcium silicate board

- Q: Decoration problem: a calcium silicate board about how many customers want me to calculate the weight. The Trouble trouble trouble.

- A 1220 * 2440 calcium silicate board is about 3KG. Wrong, sorry To the thickness of 8MM board as an example: 122CM * 240CM * 0.8CM = 23814CM3 About 20KG

- Q: What is high strength microporous calcium silicate board

- The problem is not clear, the calcium carbide board with calcium silicate board is not the same thing, it is completely different products, microporous calcium silicate board compared to the advantages of ordinary calcium silicate board is mainly density, manufacturing process And the use is completely different.

- Q: Silicon calcium board is not the fire board silicon calcium board is not the fire board

- Calcium silicate board is made of inorganic mineral fiber or cellulose fiber and other loose short fiber as a reinforcing material, with siliceous-calcium material as the main cementing material, pulping and molding, accelerating the curing reaction in high temperature and high pressure saturated steam to form Calcium silicate gel made of the plate. .[1] Is a good performance of the new building and industrial sheet, its products fire, moisture, noise, insect moth, durability is better, is the ceiling, cut off the ideal decorative plate.

- Q: Is calcium carbonate board containing asbestos poisonous?

- There is micro-toxic, calcium silicate to stimulate the eyes and respiratory system, asbestos itself is not toxic, its greatest harm from its dust, when these small dust is inhaled into the body, will be attached and deposited in the lungs, causing the lung Department of disease, asbestos has been recognized by the International Cancer Research Center for carcinogens.

- Q: Calcium silicate board is not keel, you can directly nail on the wall?

- Yes, but the premise is that the wall must have a good flatness, otherwise, after the installation of the surface will be uneven.

Send your message to us

Low Price Calcium Silicate Board With High Quality

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords