Light Weight Calcium Silicate Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

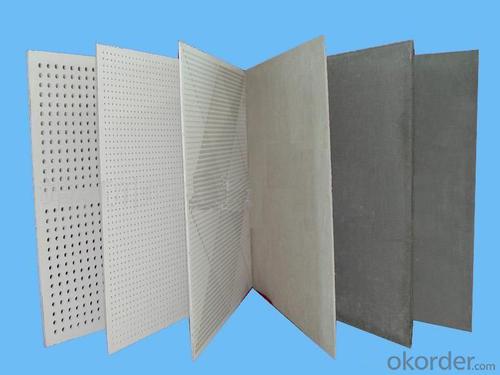

light weight calcium silicate board

1.Density:220Kg/M3

2.Service Temp:1000C

3.1000*500,600*300, 900*600,1200*600mm

4.ISO9001

light weight calcium silicate board

Product Advantages:

Product characteristics:

² Good durability, can bear high temperature within the limit of continuous heat load,

² Low thermal conductivity, in the whole range are used with unmatched adiabatic performance.

² Light weight, high strength. It is the highest in these hard thermal insulation products.

² Better durability, use for a long time without powder.

² Construction with ordinary carpenter applicability, tools can be optional cut products.

² Used safety, hygiene. Excluding asbestos, sulfur, chlorine such poisonous substances.

² Fear water, but after drying also can be used.

HCS Physical Performance Index

Main Product Features:

Items | Unit | HCS-170 | HCS-220 | HCS-270 |

Bulk Density | Kg/m3 | 170(±10%) | 220(±10%) | 270(±10%) |

Pressure Strength | MPa | ≥0.40 | ≥0.50 | ≥0.60 |

Flexural Strength | MPa | ≥0.30 | ≥0.35 | ≥0.40 |

Thermal Conductive | W/m.k | ≤0.048 +0.00011t | ≤0.050 +0.00011t | ≤0.056 +0.00011t |

Temp. limit | degrees | 1000 | 1050 | 1050 |

Linear Shrinkage | % | ≤1.50 (1000,3hrs) | ≤1.50 (1000,3hrs) | ≤1.50 (1000,3hrs) |

Product Specifications:

Block Sizes and Dimensional Tolerances

Length(±3mm) | Width(±3mm) | Thickness(+2mm,—1.5mm) |

610 | 303,300,150 | 25—140 |

600 | 300 | 25—140 |

400 | 250 | 25—140 |

1000 | 500 | 25—140 |

1200 | 600 | 25—140 |

We also supply special size and type.

Images:

- Q: Calcium silicate board ceiling, wall patchwork and vertical degree how to control?

- If the tile is affixed to the top of the case, on the side of the wall from the ground 230-240cm high point, with a transparent water pipe fixed on the other side of the wall coincide point and then line, to determine the hole after drilling with diamond drill bit The

- Q: Home wall with a good board or silicon calcium board

- People to lime (all kinds of calcium materials can be used, such as cement, etc.), quartz powder (all kinds of siliceous materials can be used as the main body to fiber as a reinforcing material mixed with water made of slab, and then autoclaved Conserved lightweight plates are called calcium silicate boards.

- Q: Calcium silicate board and magnesium silicate board which is better

- Calcium silicate board is made of paper fiber, high purity silicon, calcium raw materials, high temperature curing made of decorative materials, with fire, moisture, insulation, insulation, noise, deformation, etc., durable for up to 30 years The

- Q: How to build calcium silicate board mill, how much money

- Specific raw materials are plant fiber mineral fiber (asbestos) cement, limestone quartz sand, etc. according to the scale of investment of millions to tens of millions.

- Q: Calcium silicate board The so-called asbestos board is really no asbestos?

- This is your understanding of the errors, the autoclave temperature is about 180 degrees. Non-asbestos does not represent zero asbestos, in accordance with the provisions of asbestos content of not more than 5% can be called asbestos-free, the real non-asbestos only domestic and Taiwan. If they find a bit asbestos in their company, Taiwan Rong reward 100,000 yuan, if dare to promise that is the real asbestos calcium carbonate board

- Q: Calcium silicate board is not gypsum board?

- No, calcium silicate board and gypsum board is completely different from the two materials, but because of the use of almost, so easy to confuse.

- Q: Calcium silicate board water absorption on the performance of the plate have any effect

- Calcium silicate board if the water after the impact of the plate have a certain impact, but will not loose will not be deformed, and then back to the plate after the original strength will be restored

- Q: Decorated with calcium silicate board to do the ceiling after the discovery of which contains asbestos ingredients. With the putty powder and paint brush brush is it harmful to the body only two of the impact of it?

- Asbestos has a high degree of fire resistance, electrical insulation and thermal insulation, is an important fire, insulation and insulation materials, after joining the anti-cracking effect, and some are added anti-cracking fiber. So that there is no impact.

- Q: What is the difference between inorganic silicate composite board and inorganic calcium silicate board?

- Calcium silicate board is made of inorganic mineral fiber or cellulose fiber and other loose short fiber as a reinforcing material, with siliceous-calcium material as the main cementing material, pulping and molding, accelerating the curing reaction in high temperature and high pressure saturated steam to form Calcium silicate gel made of the plate. Is a good performance of the new building and industrial sheet, its products fire, moisture, noise, insect moth, durability is better, is the ceiling, cut off the ideal decorative plate.

- Q: Will silicon calcium plate become moldy?

- Short time water seepage, and timely drying, keep the ventilation is not mildew. If there is easy to mold the impurities inside the silicon calcium board and glue, and in the long-term humid, non-ventilated environment, it may be mildew.

Send your message to us

Light Weight Calcium Silicate Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords