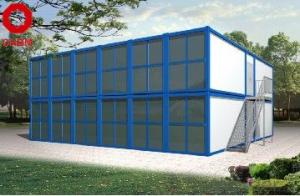

Comfortable Dwell Container House

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Sets set

- Supply Capability:

- 20000 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

dwell container house

1.ISO9001:2008 Certification container house

2. life span of more than 15 years

3.Customer des

Detailed Product Description

dwell container house :

1. no base wor

2. easy to installing and low-cost

3. demountable, easy to transport

4. robust structure

Materials of the container house:

|

Frame Structure |

cold formed profile steel, 4mm thick | |

|

Corrosion Protection |

polishing, derusting, sand blasting | |

|

Primer Coat |

epoxy zinc-rich primer, two layers | |

|

Finishing Coat |

alkyd honed painting | |

|

Flooring |

25mm calcium silicate board + vinyl flooring | |

|

Wall panel |

60mm EPS steel sandwich panel, with metal strip on side | |

|

Roof |

corrugated steel plate, 2mm thick | |

|

Ceiling |

50mm EPS steel sandwich panel with mineral wool | |

|

Door |

Aluminum frame with composite door | |

|

Window |

UPVC swing window or sliding window | |

|

Internal Skirting |

plastic, in white | |

Characteristics:

1.No base work involved

2Environment protective, no garbage caused.

3.Doors, windows, and interior partitions can be flexibly fixed.

4.Beautiful appearance, different colors for the wall and roof.

5.Cost saving and transportation convenient.

6.Anti-rust and normallymore than 15 years using life.

7.Safe and stable, can stand 8 grade earthquake.

Technical parameters:

1.Wind resistance: grade 11 (wind speed ≤111.5km/h)

2.Earthquake resistance: grade 8

3.Live load capacity of roofing: 0.5kN/m2\

4.External and internal wall heat transmission coefficient: 0.35Kcal/m2hc

5.Usage: offices, dormitory, hotel, remote building site, portable toilet and etc.

6.Package: flat package, all components are well wrapped.

- Q: Spherical roller bearing and bearing seat that match?

- Yes, as long as the national standard is available

- Q: I see, manual roller bearings, bearing room width is significantly greater than the width of the applicable bearings (bearing room 65, bearing thickness only 37), I would like to ask the outer ring bearings in the bearing seat in the axial direction of how to fix, plus GASKET?

- Must be fixed, you can use the ring, but a group of general use, it is a fixed, one is not fixed, you can guarantee horizontal movement

- Q: What type of bearing does the bearing block of SN220 match?

- The bearings are available in 22220, 23220, 1220, 2220, 3520 and 6220.

- Q: How can I check the concentricity of the bearing seat?

- With a dial indicator, (measuring) (measurement) platform, guide rail, bearing axial check circle around the next beat is super bad

- Q: How to solve the looseness of pump bearing seat and bearing sleeve? Please be specific. Thank you

- 1. Change the slightly larger bearings.2, in the bearing coat lining to write the back of the red copper skin, and then knock in. As the degree of loosening the thick thin copper lining decided, if you do not need full circle lining lining can keep several points, several points are symmetrical.3, with 2 or more steel pad at the seam, and then knock bearing, so that steel wire forming pin. Attention symmetry.4, into the bearing, with the sample punch in the shaft seat close to the location of the shaft, symmetrical knock a few points, so that a little deformation of the axle seat, squeeze the bearings.

- Q: Tapered roller bearings. The installation is complete except for the shaft ends. Therefore, only with glib lubrication.

- Relatively large bearing housings usually in the top (center, vertical). Also according to the application, consider the convenience of refueling, the oil hole design is 45 degrees or 135 degrees away from the center of the bearing, but can not be added below

- Q: Is not each bearing can use the bearing seat, that can use the bearing seat of what kinds of bearings, as well as the bearing seat is divided into which kinds?

- The bearing can be used as a support, but also can be used as a guide, as time support, there must be external shell seat, the bearing seat, but many, bearing the form of square, round, some is not necessarily the bearing seat we usually see, for example, some non-standard bearings seat, but its internal structure design must be determined according to the installation dimensions and types of bearings, the bearing structure of internal and external elements of different types may not have the same, according to your actual installation position and transmission requirements and bearing type to determine; as a guide, do not need bearing the seat, because of different functions, as a guide bearing and material point contact, so as to reduce friction, but also played a guiding role.

- Q: Can the rolling bearing be fixed with a sliding bearing seat?

- Can not. The structure of the two is different. Sliding bearing structure is simple, its fixed method can be changed according to circumstances, but the rolling bearings, sub ball bearings, roller bearings and other types, different types of rolling bearings are different methods of fixation. This should be determined in combination with the specific mechanical structure.

- Q: Selection of tolerances for bearing housings?

- It's usually like H7

- Q: RT excuse me, what's the difference between square bearing housings UCF and UCFX? Apart from the size and matching of the bearing units, what are the differences? Why do you need another model for UCFX?

- 1, UCF. is the regular 2 series, and the UCF3 series is commonly used. You UCFX is a series derived from the 2 and 3 series!2, the size between the two series of small, specific function parameters and design are the same, is the difference in size, if there is no center of high demand, can generally be replaced, most will cushion, can solve the problem, will not affect the overall performance!

1. Manufacturer Overview

| Location | Guangdong,China |

| Year Established | 2007 |

| Annual Output Value | USD81,971,845.00 |

| Main Markets | North America;South America;Southeast Asia;Africa;Oceania;Mid East;Eastern Asia;Domestic Market |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | foshan,guangzhou,shenzhen |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 30,000-50,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | High and/or Average |

Send your message to us

Comfortable Dwell Container House

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Sets set

- Supply Capability:

- 20000 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords