Colorful Coated Aluminum Coil - Hot Items 1, 3, 5 Ultra Thick Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hot Items 1, 3, 5 Ultra Thick Aluminium Sheet

l Product Information

Product | Alloy designation | Supply status | Thickness(mm) | Width(mm) | length(mm) |

Quench aluminium plate | 2 series, 6 series, 7 series | T3,T4,T42, T6,T62,T73, T74 | 0.5~150 | Under 2000 | Under 11000 |

Pre-stretching version plate | 1~8 series | Various forms | 2.0~180 | Under 1600 | Under 4000 |

Checkered plate | 1 series, 3 series, 5 series | H224,H114, O,H234 | 1.0~8.0 | Under 1900 | Under 12000 |

Hot rolled plate | 1~8 series | F,H111,H112 | 4.0~300 | Under 2200 | Under 11000 |

Hot rolled stock | 1~8 series | F,H111,H112 | 4.0~15 | Under 2300 | C |

Plate | 1~8 series | Various forms | 0.15~300 | Under 2200 | Under 12000 |

Coiled material | 1~8 series | Various forms | 0.15~15 | Under 2200 | C |

Air-conditioning foil | 8011,3012 | H22,H24 | 0.09~0.15 | Under 1300 | C |

Curtain wall plate | 1060,1050 , 1100,3003 3004,5052 | H14,H24,O | 1.0~5.0 | Under 2200 | Under 12000 |

Aluminium foil | 1060,1100, 8011,1235, 3003 | Various forms | 0.008~0.2 | Under 1500 | C |

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received oiginal L/C or advance payments

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

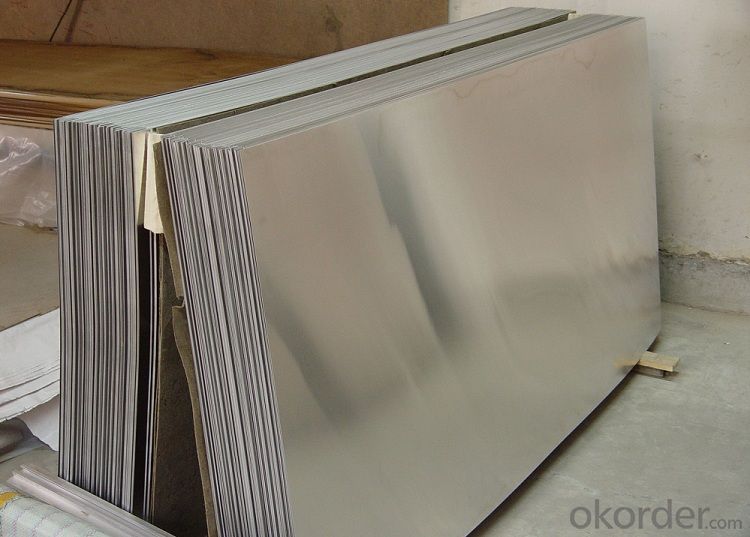

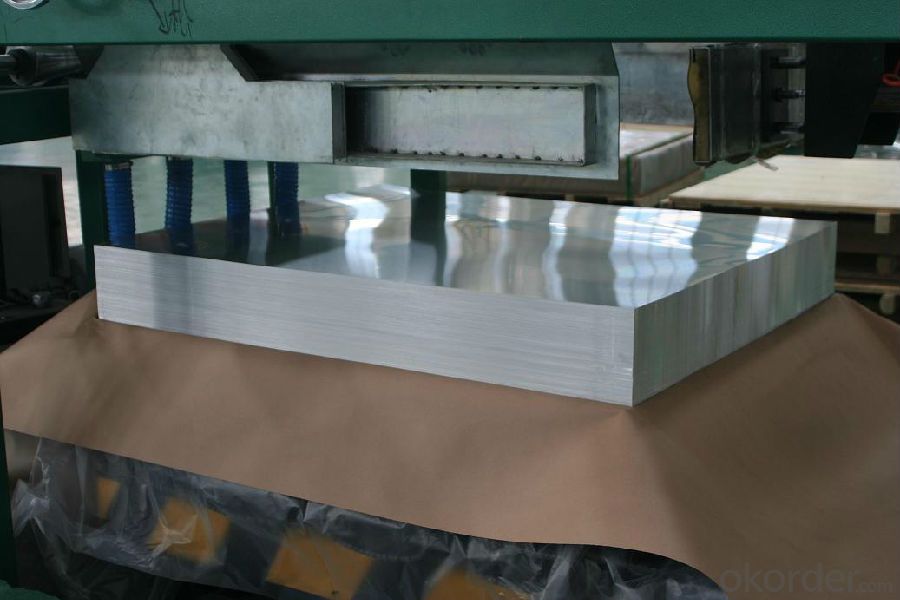

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q: What are the typical standards and specifications for packaging aluminum coils?

- <p>The standard specification for aluminum coil packaging varies depending on the industry and region, but generally includes the following: The coil is typically wrapped in a protective film to prevent damage and corrosion. It is often strapped with steel or plastic bands to secure the coil during transportation. The packaging may also include wooden pallets or crates for stability. The dimensions and weight of the packaging are tailored to the coil's size and thickness. Compliance with international standards such as ASTM, ISO, or specific industry standards is crucial. It's important to note that exact specifications can differ based on customer requirements and the end-use application of the aluminum coil.</p>

- Q: Why are the aluminum coils sticky after annealing?

- There is oil or the annealing time is too long!

- Q: Can aluminum coils be used in the production of signage?

- Yes, aluminum coils can be used in the production of signage. Aluminum is a popular material choice for signage due to its durability, lightweight nature, and resistance to corrosion. The coils can be easily shaped and formed into various sign types, including flat panels, channel letters, and more. Additionally, aluminum can be coated or painted to achieve different colors and finishes, making it a versatile option for signage production.

- Q: Almost every restaraunt uses aluminium foils and polyehylene for packing foods - that you carry to home.How safe is this ?For how long would the temperature be mainitained ?and within what time if consumed and is it safe ?

- Aluminium (Al) foil is bad for packaging because some of the Al will be absorbed by the food and too much Al is toxic. Instead of Al cooking vessels you should use stainless steel vessels because some Al will end up in your food from the Al containers or vessels. If you conduct a search for Aluminium (OR Al) poisoning you should learn more. A search for aluminium (OR Al) + toxic dose (OR amount) may also be useful.

- Q: What specific tools are necessary for handling and working with aluminum coils?

- <p>When working with aluminum coils, there are several special tools that may be required. These include cutting tools designed for metal, such as metal shears or a bandsaw with a metal cutting blade, to cut the coils without damaging the material. A coil car or lifting equipment is necessary for safely moving and positioning heavy coils. Additionally, a coil leveler may be needed to straighten and flatten the coils for processing. Safety equipment such as gloves and goggles is also essential to protect against sharp edges and flying debris. It's important to use tools that are suitable for the specific aluminum alloy and thickness to ensure efficient and safe handling.</p>

- Q: Can aluminum coils be used in packaging industries?

- Yes, aluminum coils can be used in packaging industries. Aluminum is lightweight, flexible, and has excellent barrier properties that protect the packaged products from moisture, oxygen, and light. It is commonly used for packaging food, beverages, pharmaceuticals, and other consumer goods due to its durability and ability to preserve product quality.

- Q: How are aluminum coils annealed?

- Aluminum coils are typically annealed through a process known as heat treatment. This involves heating the coils to a specific temperature and then slowly cooling them down. The purpose of annealing is to soften the aluminum and improve its ductility, making it easier to work with. The first step in annealing aluminum coils is to clean them thoroughly to remove any contaminants. The coils are then placed in a furnace, which is heated to the desired temperature. The temperature and duration of the annealing process depend on the specific grade and thickness of the aluminum being treated. Once the coils reach the desired temperature, they are held at that temperature for a predetermined amount of time. This allows for the internal structure of the aluminum to become more uniform and relieves any internal stresses that may have developed during the manufacturing process. After the annealing process is complete, the coils are slowly cooled down in the furnace. This slow cooling is important to prevent the formation of any new internal stresses. Once the coils have cooled to room temperature, they are ready for further processing or use. In some cases, a process known as quenching may be used after annealing. Quenching involves rapidly cooling the aluminum by immersing it in a quenching medium, such as water or oil. This can help to further improve the mechanical properties of the aluminum, such as its strength and hardness. Overall, the annealing process for aluminum coils is a carefully controlled heat treatment that aims to improve the metal's properties and make it more suitable for various applications.

- Q: 1) From What does aluminium derive its name?2)From which ore is aluminium extracted?3)Which country produces more aluminium than any other?4)An American and French scientist both patented the current process used to produce aluminium, what were there names?5)Who is credited with having been first to produce metallic aluminium?

- 1) From What does aluminium derive its name? Ancient Greeks and Romans used aluminium salts as dyeing mordants and as astringents for dressing wounds; alum is still used as a styptic. In 1761 Guyton de Morveau suggested calling the base alum alumine. In 1808, Humphry Davy identified the existence of a metal base of alum, which he at first termed alumium and later aluminum . The earliest citation given in the Oxford English Dictionary for any word used as a name for this element is alumium, which British chemist and inventor Humphry Davy employed in 1808 for the metal he was trying to isolate electrolytically from the mineral alumina. 2)From which ore is aluminium extracted? Bauxite 3)Which country produces more aluminium than any other? China 4)An American and French scientist both patented the current process used to produce aluminium, what were there names? Hall and Héroult 5)Who is credited with having been first to produce metallic aluminium? Friedrich W?hler

- Q: How many 1220mm*2440mm aluminum sheets can one-ton aluminum coil be sliced to? Thank you.

- You should know the thickness of aluminum sheet first, and then calculate the weight of aluminum sheet of this specification, and finally use 1T divide the weight.

- Q: What are the necessary safety measures to be taken while handling and using aluminum coils?

- <p>When using aluminum coil, safety precautions include wearing appropriate personal protective equipment such as gloves and safety glasses to prevent cuts and eye injuries. Ensure good ventilation to avoid inhaling aluminum dust or fumes. Keep the work area clean and free from clutter to prevent tripping hazards. Use proper tools to handle the coils to avoid strain or injury. Be cautious of electrical hazards if the aluminum coil is being used in conjunction with electrical equipment. Always follow the manufacturer's guidelines for safe operation and storage of aluminum coils.</p>

Send your message to us

Colorful Coated Aluminum Coil - Hot Items 1, 3, 5 Ultra Thick Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords