Colored corrugated steel roofing sheets for mobile house

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Colored corrugated steel roofing sheets for mobile house

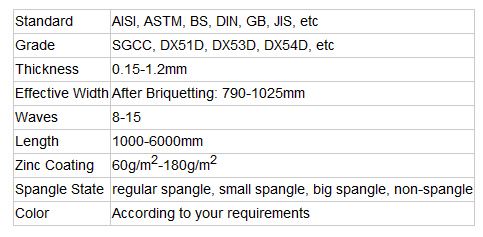

Specifications

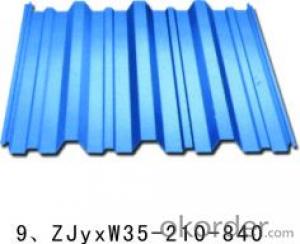

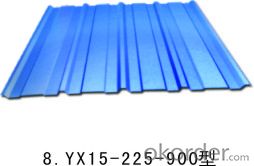

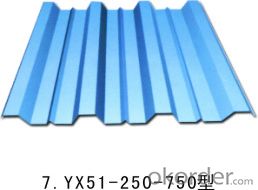

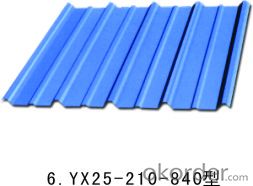

colored corrugated steel roofing sheet

1,The width is 50mm--1500mm

2,The thickness :0.14-0.45mm

3,Goods in our stock

1,Specification :

<1>pre-galvanized corrugated steel sheet:

| Thickness: 0.16 -3.0mm | Width:600mm,914mm,,1000mm, 1220mm,1200mm,1250mm | Length: Coil or client’s requirements |

| Zinc Coating:60g/m2 to 275g/m2 (G30-G90) | Spangle: zero spangle, min spangle , regular spangle ,big spangle | USAGE: building ,industrial and other fields |

| Coil ID: 508 -610mm | Coil Weight: 3-10 Ton | Type :coil or sheet |

| Packaging Detail: | Fully seaworthy export packing with paper tube |

| Delivery Detail: | about 15 working days if the quantity below 500 ton |

<2> color coated corrugated steel sheets

<3>applications:

a.) Industrial and civil buildings, warehouse;

b.) Special construction;

c.) Steel structure houses and mobile homes, roof, walls, and interior and exterior decoration, etc.

<4>our addvantage:

a.) Attractive and innovative appearance, rich colors, decorative, flexible combination, can express a different architectural style;

b.) Light weight, high mechanical properties;

c.) Anti-earthquake, fire, rain, long life, no maintenance;

d.) Installation is simple, shorten the construction period;

e.) Environmental protection, etc.

- Q: Sandwich board is how the synthesis

- Should be "sandwich board" was right. Sandwich panel products are composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the composition of the polymer core insulation. These sandwich panels are easy to install, lightweight and efficient. Filling system is also used to close the molecular structure, you can put an end to the condensation of water vapor. The forming of the outer steel sheet takes into account the structural and strength requirements, and takes into account the appearance, the inner layer is formed into a flat plate to suit various needs. Sandwich panels for large industrial plants, warehouses, gymnasiums, supermarkets, hospitals, cold storage, activities, building plus layer, clean workshop and the need to heat insulation fire places.

- Q: How about the sound insulation of the sandwich panel?

- Caigang sandwich panels as one of the main structure of steel structure, the choice is also equal to the main. Caigang sandwich board commonly used to the steel structure for us there is no unfamiliar, Caigang sandwich board is how to be cast down, the analysis is the internal sound insulation system and external sound insulation system two whole. And the roof of the lightning protection is a whole internal lightning protection system, Caigang sandwich panels and the upper structure of the connection form (to prevent the "cold bridge" scene); color steel sandwich panels for the heat radiation of the repeated power The

- Q: What are the benefits of color steel?

- First, the advantages of color-type steel plate envelope The color of the pressure-type steel plate is the surface of the chemical treatment and double-sided color coated with thin steel plate by rolling cold forming sheet, is a good performance of light, high strength, Beautiful modern building materials. Color plate used in color plate characteristics: (1) the coating has a high strength of the adhesive; (b) the coating has excellent damage to the machinability; (c) does not change the color does not crack good weather resistance (D) strong corrosion resistance; (5) flame retardant; (f) rich and beautiful color does not fade; (7) coating surface easy to wash. These features give the color plate has brought many excellent features. Plant with color plate for the envelope structure and other materials commonly used in China's envelope compared to the following advantages: (a) flexible layout, can be determined according to the needs of the process span, column spacing, unlike the reinforced concrete prefabricated components (2) section design has more choices, the roof length and slope of the limitations of small, can be set a variety of skylights, choose a variety of lighting methods; (c) facade rich and colorful, pleasant color, (4) factory production, high efficiency; (5) light weight, construction and installation of simple, change the towing water for the clean and tidy of the construction of the situation, the construction of the production of high-quality, Construction speed; (6) easy to replace the maintenance, easy to plant expansion. Color plate can also be used for civil construction, with color plate envelope structure of civil construction is unique, especially for large space stadiums, exhibition halls and other public buildings, it is more superior.

- Q: 100 thick 960 color steel sandwich board how much money one meter? What is the bulk density?

- This is not necessarily normal 8 kg, 10 kg

- Q: Sandwich composite panel and color steel tile difference which the high cost

- Sandwich panels cost high roof is usually 0.8 thick YX760 plate plate 6000 yuan / ton is calculated 49.5 yuan / square if you are processing, probably not more than 55 yuan / square; and sandwich panels are generally finished the purchase of the thinnest 50 thickness 1150 type of the board more 80 yuan / square and the installation fee because the sandwich plate is thicker than the color steel tile expensive. ???? But the use of sandwich panels is different from the color steel tiles, such as model rooms and the need for sound insulation of the plant (general foreign enterprises plant) will use sandwich panels; and if only to do storage, processing lines, non-heavy noise pollution recommended The cost of relatively low color steel tile ~ ~

- Q: anxious! Will the polyurethane sandwich panels of various parameters, plant design!

- Polyurethane is a two-component AB material (isocyanate and combined polyether) mixed foam, is the thermal insulation material in the lowest thermal conductivity of 0.017 ~ 0.024 (thermal conductivity of the lower the better insulation). Polyurethane sandwich panels used in the filling process of polyurethane, pre-made pre-insulation board directly installed on-site use. If your plant area is relatively large, it is recommended that you only use the whole color plate, and then use the field of polyurethane spray foam process, this process than the infusion process is the advantage of spraying seamless, better insulation. The cost is still lower than the infusion process.

- Q: Color steel sandwich panels and C steel belongs to what industry

- Should be considered building materials it Make the house with the thing.

- Q: 50mm thick roof color steel sandwich board price is generally how much money a m2?

- 50mm thick roof sandwich board is generally 65 yuan per square main to see how thick you want the steel plate

- Q: Color steel sandwich panel of the scope of what, what is the benefits of this sandwich board, the purchase of the price of the number of appropriate? Housing construction with this sandwich board can

- Printing color steel are applicable to the sandwich board industry, not to mention monochrome steel, and now has a composite plate steel structure, activities, external walls of metal carved panels, integrated insulation board, light steel villas and so can be used, , Rich colors, is a new type of energy saving and environmental protection composite materials, the price can go to contact Jiangyin Wo Fung metal, as if the price is not the same price, is based on your requirements to account, sandwich board used in the house certainly no problem.

- Q: What are the requirements for the use of foam sandwich panels for fireworks

- Roof absolutely do not use, the wall can discuss to reach the fire rating

Send your message to us

Colored corrugated steel roofing sheets for mobile house

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords