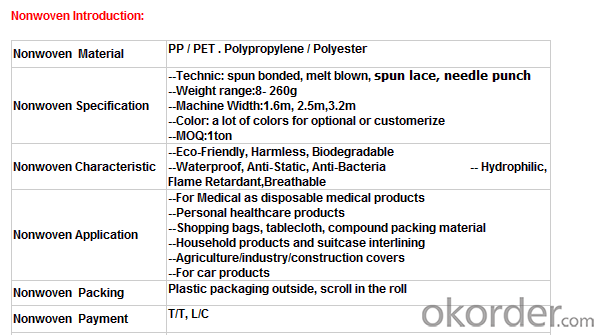

Waterproof Polyester Spunbond Nonwoven Fabric Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Eco-friendly Polypropylene PET Spunbond Non-woven Fabrics Made in China

Our products have been widely used in the field of medical& sanitary, industry &agriculture, and construction &daily-used products such as agriculture plant covers, roof waterproof materials, disposable items for medical and industrial applications, liners for furniture, lining in cases,apparel, warm facilities, bedding products, sofas, packing materials, packing material land mulriple cloth shopping bags, suits and garment covers, Industrial protective coveralls, garment accessory materials, bed articles, medical and sanitary articles as well.

Our Service:

Within 24 hours reply ;

Well-trained and experienced staffs in English;

OEM & ODM , Customized are warmly welcomed , or design for you ;

Protecting customer’s privacy and profits;

Make sure the quality is approved , or we pay the return or remake them at once .

Nonwoven Advantage:

1. Light: Polypropylene is the main raw material; specific gravity is 0.9, is only third five, fleecy and touches well.

2. Flexibility: made up of microfiber (2-3D), dot by dot thermo-melt formed. Flexibility of products is suitable, comfortable.

3. Water resistance and breathability: slices of Polypropylene and finished products resist water, breathable and easy to maintain and wash.

4. Non-toxic, non-irritating: made of materials which catch up FDA standard, without other chemical composition, stable, non-toxic, no smell, safe for sensitive skin.

5. Anti-bacterial, anti-chemical: Polypropylene is blunt chemical substances can protect in liquid from bacterial and insects; antibacterial, alkali corrosion, erosion and the finished product will not affect sensitive skin.

FAQ:

Q: What standards are you carrying out for your products?

A: We produce according to the ISO9001 and ISO14001 rules.

Q: How to install the machine?

A: We will arrange 1~2 engineers to your factory to guide installation and assembly.

Q: What’s your international market?

A: We Have exported to about 40 countries and regions all around the world, such as, the USA, France, Singapore, Australia, Middle East, Brazil, Peru and so on.

Q: Do you sell steel shot or steel grit which can be uses in shot blasting machine?

A: We have four production lines for steel shot and steel grit production, one work shop for steel cut wire shots, and one workshop for stainless steel shot and Aluminium shot and so on.

Q: Do you have the right to export?

A: Yes, we registered in the Customs and gained the right to export by ourselves.

- Q: Sponges are plastic or textiles

- As well as shock-resistant, anti-friction applications such as elastic materials, such as soles, tractor tanks. Sponge production process is as follows

- Q: How to make fibrous textiles for waste plastic bottles?

- Jiangsu, a textile company to Beijing during the Olympic Games recycling waste plastic beverage bottles, the use of some surprising, the production of sports textile products! At the same time, Zhejiang Xiaoshan four companies at home and abroad extensive acquisition of waste plastic bottles, processed into fiber and then exported, one year consumption of 1 billion plastic bottles, the annual output value of over 500 million yuan

- Q: The development of wool in Australia is not developed.

- The main trading partners are Japan, the United States, mainland China, South Korea, Britain, New Zealand, Singapore, China Taiwan Province, Germany and Malaysia.

- Q: What are the types of textiles that are different?

- According to the use can be divided into clothing with textiles, decorative textiles, industrial supplies three categories;

- Q: What is the number of raw materials for textile enterprises?

- General varieties are used, PVA, modified starch and other main pulp, plus propylene and wax tablets and other additives,

- Q: Classification of antimicrobial textiles and their characteristics

- Natural antimicrobial materials mainly to hemp and chitin-based, which linen products at low prices, the market acceptance is relatively high.

- Q: Textile enterprises to operate the project: processing and production are different?

- And production from the beginning of raw materials, such as from the thread to the weaving, made of cloth and then made into clothes.

- Q: What is eco textile?

- Eco-textiles are those that are made of raw materials that are harmless or less harmful to the surrounding environment and are harmless to human health. Eco-textile content 1. Production ecology

- Q: What are the raw materials for textiles?

- You can wall wall (tapestry), not afraid of the fire and the fire (asbestos cloth, fire clothes). Like Weng woman to Tong Yan (actor dressing veil), really for the soldiers to add wings (parachute). Can protect the rocket head (aramid fiber fabric), can be used for bulletproof clothing. Enough to filter (functional fiber), where fear of electric shock (live operation taking the pressure of silk). Beauty Kam, embroidery (embroidery), odd with tapestry.

- Q: What kind of textile is China's export to the United States?

- China's exports to the United States of textile clothing, clothing accounted for about 70%, about 30% of textiles. In 2006, China's textile and garment exports to the United States reached 21.9 billion US dollars, an increase of 18%, of which clothing was 16.3 billion US dollars, accounting for 74% of all exports to the United States; textiles for 5.6 billion US dollars, accounting for 26% The

Send your message to us

Waterproof Polyester Spunbond Nonwoven Fabric Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches