color Rolled Galvalume Steel Coil for Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Color Rolled Galvalume Steel Coil for Roof

Description of Color Rolled Galvalume Steel Coil for Roof

Aluminum zinc coils is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Color Rolled Galvalume Steel Coil for Roof

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Color Rolled Galvalume Steel Coil for Roof

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

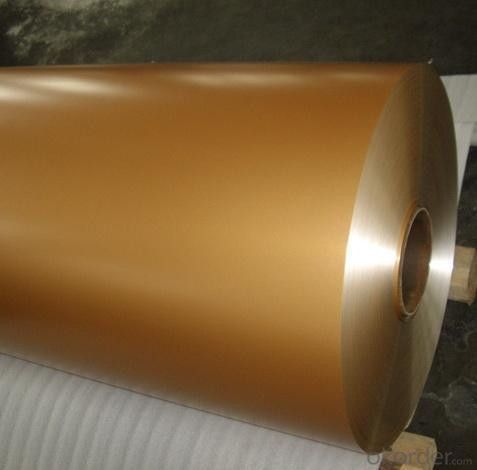

Color Rolled Galvalume Steel Coil for Roof Images

Specifications of Prepainted Aluminum Zinc Rolled Coil for Construction

Chemical Composition | ||||||

GRADE | C | Si | Mn | P | S | Ti |

SGCC/DX51D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

DX52D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

SGCD/DX53D+Z | ≤0.10 | ≤0.30 | ≤0.50 | ≤0.05 | ≤0.030 | ≤0.020 |

SGCE/DX54D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

DX56D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

Structural | ≤0.20 | ≤0.60 | ≤1.70 | ≤0.10 | ≤0.045 | |

Mechanical Properties | ||||||

GRADE | Yield Strength MPa | Tensile Strength MPa | Elongation % | |||

SGCC(DX51D+Z) | ≥205 | ≥270 | - | |||

SGCD(DX53D+Z) | - | ≥270 | 38 | |||

SGCE(DX54D+Z) | - | ≥270 | 40 | |||

DX56D+Z | - | ≥270 | 42 | |||

FAQ of Prepainted Aluminum Zinc Rolled Coil for Construction

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the benefits of using coated steel coils in roofing applications?

- There are several benefits of using coated steel coils in roofing applications. Firstly, coated steel coils are highly durable and provide excellent resistance against corrosion. The coatings applied to the steel coils act as a barrier, protecting the underlying metal from exposure to moisture, chemicals, and harsh weather conditions. This ensures that the roofing system remains intact and functional for an extended period, reducing the need for frequent repairs or replacements. Secondly, coated steel coils offer superior strength and structural integrity. Steel is known for its high tensile strength, and when combined with the protective coating, it becomes even more resilient. This makes coated steel coils an ideal choice for roofing applications, as they can withstand heavy loads, extreme temperatures, and strong winds without compromising the integrity of the structure. Additionally, coated steel coils are lightweight, which makes them easier to handle and install. This not only saves time and effort during the roofing process but also reduces the overall weight of the structure, minimizing the stress on the building's foundation. Furthermore, coated steel coils are available in a variety of colors and finishes, allowing for greater design flexibility. Architects and homeowners can choose from a wide range of options to complement the overall aesthetics of the building. The coatings also provide enhanced UV resistance, preventing color fading and ensuring that the roofing system maintains its appearance over time. Lastly, using coated steel coils in roofing applications is an environmentally friendly choice. Steel is a highly recyclable material, and the coatings used on the coils can be formulated to be environmentally friendly as well. This helps reduce the carbon footprint associated with construction and promotes sustainability. In conclusion, the benefits of using coated steel coils in roofing applications include durability, strength, lightweight, design flexibility, and environmental sustainability. These advantages make coated steel coils a reliable and cost-effective choice for any roofing project.

- Q: How are steel coils used in the production of conveyor systems?

- Steel coils are used in the production of conveyor systems as they are transformed into various components such as conveyor belts, rollers, and frames. These components provide the necessary strength, durability, and support required for efficient material handling and transportation in conveyor systems.

- Q: This question is directed to anyone who has played or know someone who plays a lap or pedal steel guitar.I've been a guitarist for about 8 years now and have played a variety of styles from rock, fingerstyle/classical, singer/songwriter acoustic stuff, ect, and now I've really had an interest in learning how to play a lap steel or pedal steel guitar. I am completely new to the instrument(s), so I'm seeking all the information I can. I do know that a pedal steel is a lot more expensive, so I'm probably looking to start on a lap steel for now. Basically how should I get started? Should I find a cheap lap steel at a pawn shop or purchase something new? Are there any good method books out there? I'm a pretty experienced guitarist, so should I expect to get the hang of it quickly? Is there much of a market for a lap/pedal steel player? haha.Also, I am left handed. How much trouble would it be to re-string a steel guitar? Or would I be better off getting a left-handed model?

- Hello okorder / I'm not familiar with the brand...it's certainly not commonly played....but it has the features you need for a starter guitar.

- Q: How do steel coils resist corrosion?

- Steel coils resist corrosion due to the protective layer formed on their surface. This layer, known as a patina, acts as a barrier between the steel and the surrounding environment, preventing moisture and oxygen from reaching the metal and causing oxidation. Additionally, steel coils can be coated with corrosion-resistant materials such as zinc or paint to further enhance their resistance to corrosion.

- Q: What are the different coil handling equipment options available for steel coils?

- There are several options available for handling steel coils, including coil cars, coil upenders, coil lifters, coil tilters, and coil transfer carts. These equipment options are designed to safely and efficiently transport, position, and manipulate steel coils during various stages of the manufacturing process.

- Q: I had a damascus steel katana made for me and was wondering if I could put gun blue on it to make the steel black and it still work right

- There are many makers that use blue on there Damascus. My question, what the heck are you wanting to mess with the finish for? If you had a true Damascus blade made that that thing cost a fortune, and I don't mean under a grand either. Then there is the question of what it is made from, some steel combinations react well to the gun blue, others not so much. If it is a stainless blade it won't work at all and you shouldn't be using it either. I can tell you, my Damascus blades start at $100 for a small cable knife and go up from there. If you wanted a sword it would push 10 g's easy. None of my customers would mess with the finish, most would cry if it got scratched. If it's has a pretty pattern don't mess with it.

- Q: Is there alloys in low carbon steel or non

- Hello, okorder Hoping this can help you. :-)

- Q: How are steel coils used in the manufacturing of HVAC systems?

- Steel coils are used in the manufacturing of HVAC systems primarily for heat transfer purposes. They are typically used in air conditioning and refrigeration systems to facilitate the transfer of heat between the refrigerant and the surrounding air. The coils, usually made of copper or aluminum tubes with steel fins, are designed to maximize the surface area available for heat exchange, allowing for efficient cooling or heating of the air passing through the system.

- Q: How are steel coils used in the production of industrial shelving?

- Steel coils are used in the production of industrial shelving as they are typically cut and shaped into various components, such as uprights, beams, and braces, which are then assembled to create sturdy and durable shelving units. The coils provide the necessary strength and stability required to support heavy loads and withstand the demands of an industrial environment.

- Q: The Chinese invented the windmill long before the 1800's, but I cannot find anywhere who invented the steel windmill, I believe it was in the 1800'sIf you know the answer that'd be great!And also if you could find the date it was patented? Thanks SO much!

- The Steel Eclipse Type WG was the first of several self-oiling steel windmills marketed by Fairbanks, Morse, and Company after they became the distributor of all the Eclipse mills about the start of the 20th Century. It has the more important distinction of having been the only widely distributed worm-gear mill in the history of American windmill manufacture. Produced from about 1926 to the mid-1930's, the Steel Eclipse remains in the field today in considerable number in most parts of the country. Hope this helps!

Send your message to us

color Rolled Galvalume Steel Coil for Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords