Color Coated Steel Coils Pre-painted Aluzinc Steel Coils/ Sheets /PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Application of Color Coated Steel Coils Pre-painted Aluzinc Steel Coils:

Construction, the manufacturing of cars, ships,containers and household electric appliances, other industries usage,they are mainly used in construction, light industry, automobile, agriculture, animal husbandry, fishery and commerce, etc industries.

2.Features of Color Coated Steel Coils Pre-painted Aluzinc Steel Coils:

.Manufacture anticorrosion, industrial and civil architecture roof boarding, roof grille.

.Make home appliance’s case, civil chimney, kitchen utensils, etc.

.Corrosion resistant parts of cars

.Food storage, meat and aquatic products’ freezing and processing equipment etc;

.The equipments to store and transport materials, and packing implements.

3.Details of Color Coated Steel Coils Pre-painted Aluzinc Steel Coils:

Size | (0.13mm-5.0mm )*(600mm-1500mm)*coil |

Steel Grade | JIS G3302 SGCC~SGC570,SGCH(FULL HARD-G550),SGHC~SGH540 EN 10346-DX51D+Z,DX53D+Z, S250GD~S550GD ASTM A653M CS-B, SS255~SS550 |

Coil Weight | 3MT-14MT |

Coil ID | 508mm/610mm |

Chemical Treatment | Chromated(Cr 3+,6+,0+) |

Surface | Skin pass/non skin pass |

Oil | Slight Oiled/Dry |

Spangle | Regular/Zero/Big |

Zinc Coating | Z40-Z300 |

Capacity | 1,500,000MT/year |

Mill Origin | HBIS-Tangsteel,Shandong Zhongguan, Changshu Everbright, WISCO |

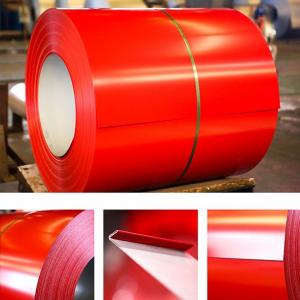

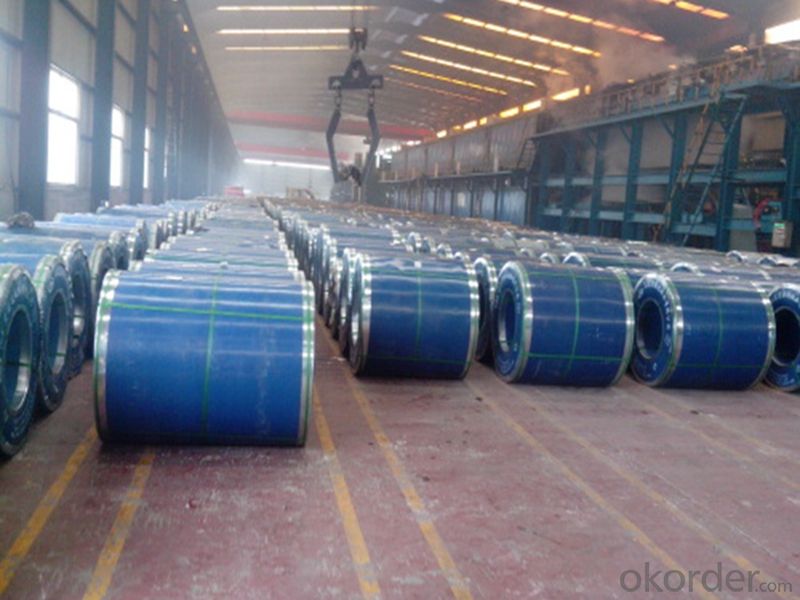

4.Color Coated Steel Coils Pre-painted Aluzinc Steel Coils image:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: im buying a sword and i dont know if i should buy a cold steel sword or a normal sword and that i can some how make that cold steel

- Cold Steel takes a billet (read piece of metal stock) in high carbon steel, usually 1060 which is pretty good, and then heats it up and pounds it into shape with a pre-made form. This is called forging. Their swords are not Folded (the traditional manner) they are Forged. This is different from taking a piece of 1060 steel and just grinding it down into shape. The forging process creates very strong steel (not as strong as folding) that is much stronger than a sword or knife made from grinding a piece of metal down into shape. Cold Steel's stuff is generally thicker, but they are practical and with enough practice you can wield it just like a thinner lighter sword. Their weapons are what you would call battle ready meaning you could feasibly take it into a sword fight and use it like its more traditionally crafted counter part. The only downfall is its weight and and the fact that it isn't as strong as a folded steel sword, but it would do very well.

- Q: What are the safety regulations for handling steel coils?

- The safety regulations for handling steel coils typically include wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and steel-toed boots. Additionally, workers are often required to receive proper training on safe lifting techniques and use of equipment, as well as understanding the weight and dimensions of the coils being handled. It is important to ensure a clear and organized work area, secure stacking and storage practices, and the use of appropriate lifting equipment, such as cranes or forklifts, to minimize the risk of accidents, injuries, and damage to the coils or surrounding infrastructure.

- Q: can anyone tell me the way to bring back the shine to the stainless steel kitchen sink . It has become dull.

- after cleaning the sink, wipe down with a small amount of baby oil. it will shine like new.

- Q: What are the dimensions of steel coils used in the agricultural machinery industry?

- The specific application and requirements play a significant role in determining the dimensions of steel coils utilized in the agricultural machinery industry. Generally, the dimensions of steel coils in this industry fall between 0.5 and 2.0 millimeters in thickness and 600 to 1500 millimeters in width. These dimensions are commonly utilized for agricultural machinery components like panels, frames, brackets, and reinforcements. It is worth mentioning that these dimensions can be tailored to meet the specific needs of the machinery or the manufacturer's specifications.

- Q: What are the advantages of using steel coils?

- There are several advantages of using steel coils. Firstly, steel coils are highly durable and have a longer lifespan compared to other materials, making them ideal for long-term use. Additionally, steel coils have excellent strength-to-weight ratio, allowing them to withstand heavy loads without compromising structural integrity. They also provide superior resistance to corrosion, making them suitable for various environments, including high humidity or coastal areas. Furthermore, steel coils can be easily recycled, making them an environmentally friendly choice. Overall, the advantages of using steel coils include durability, strength, corrosion resistance, and sustainability.

- Q: What are the different types of steel coil finishing processes?

- There are several different types of steel coil finishing processes that are used to enhance the appearance and properties of the steel coils. Some of the common types include: 1. Hot-dip galvanizing: This process involves immersing the steel coil in a bath of molten zinc, which creates a protective layer on the surface of the coil. This not only enhances the corrosion resistance of the steel but also provides a smooth and visually appealing finish. 2. Cold rolling: Cold rolling is a process in which the steel coil is passed through a series of rollers at room temperature to reduce its thickness and improve its surface finish. This process can impart a variety of finishes, ranging from a matte to a highly polished surface. 3. Electro-galvanizing: In this process, a thin layer of zinc is applied to the surface of the steel coil through an electrolytic deposition. Electro-galvanizing is commonly used for applications that require a thinner zinc coating and a more uniform finish. 4. Pickling and oiling: Pickling involves treating the steel coil with an acid solution to remove any scale or surface impurities, resulting in a clean and smooth surface. After pickling, the coil is usually coated with oil to prevent rusting during storage and transportation. 5. Powder coating: Powder coating is a popular finishing process that involves applying a dry powder to the steel coil and then curing it under heat to form a durable and attractive finish. This method allows for a wide range of colors and finishes to be applied to the steel. 6. Paint coating: Similar to powder coating, paint coating involves applying a liquid paint to the surface of the steel coil. This process can provide a decorative finish while also offering protection against corrosion and other environmental factors. These are just a few examples of the different types of steel coil finishing processes. The choice of the finishing method depends on the specific requirements of the application, such as the desired appearance, corrosion resistance, and durability.

- Q: How do steel coils contribute to energy efficiency?

- Steel coils contribute to energy efficiency in several ways. Firstly, steel coils are lightweight and can be easily transported, reducing the energy consumption associated with transportation. Additionally, steel coils have high heat transfer properties, allowing for more efficient heat exchange in various applications such as HVAC systems. Moreover, steel coils are durable and long-lasting, reducing the need for frequent replacements and saving energy associated with manufacturing new coils. Lastly, steel coils can be recycled, reducing the energy consumption and environmental impact of producing new steel. Overall, the use of steel coils promotes energy efficiency by reducing energy consumption, improving heat transfer, and facilitating recycling.

- Q: Explain your answers please. I was watching mythbusters and they bought a steel coffin over a wooden one because they thought it would hold more dirt. Now how come bridges that have been made of wood lasted way longer than steel bridges? Or rollercoasts for example.

- Back when I was in school we used to have a contest comparing balsa wood bridge designs. The idea was to build the strongest bridge when derated for bridge weight. The strength test was that the 2-ft long bridge was placed between two tables and a garbage can was strung up to the middle of it. Then it was slowly filled with water until the bridge snapped. The can was weighed and divided by the bridge weight to get our scores. I don't see why you couldn't do this to compare wood vs steel. You could find how much load is needed to snap sample rods. The important point is that the rods should be nearly identical in dimensions between the two materials-- this means length and diameter. Also if you're measuring steel, you'd want to choose a relatively thin diameter or a long span or you won't be able to even bend it. Also while I'm pretty sure wood will snap, steel might bend gradually, so you'd have to decide how much deformation you would allow before calling the piece failed. Also if you take this approach be sure to wear safety glasses when running it. In fact it would be a good idea to put a metal shroud around the test structure.

- Q: Question about steel type used in bridges.?

- It is used for other things besides bridges and that might be a bad use. Corten was used for very tall light standards in the Fort Worth Water Gardens with the clear understanding that it was to be kept dry. As time passed and personnel changed, somebody decided the round base with bolts sticking up was ugly and put dirt and plantings in the basin in the concrete holding the poles. The watering of the plants kept the rust going through the steel and one pole eventually fell, killing two people. The other light poles were removed.

- Q: What are the common uses of cold rolled steel coils?

- Cold rolled steel coils have a wide range of common uses such as in automotive manufacturing, construction, appliances, furniture, and general engineering applications.

Send your message to us

Color Coated Steel Coils Pre-painted Aluzinc Steel Coils/ Sheets /PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords