Color Coated Pre-Painted Steel Coil in High Quality in Blue

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1:Pre-Painted Galvanized/Aluzinc Steel Coil Description:

Pre-painted Galvanized/Aluzinc Steel Coil with GI or Aluzinc as base metal,after pretreatment,degrease , chemical treatment and liquid dope with several layers of color ,then after fring and cooling ,finally become pre-painted galvanized/aluzinc steel with good capable of decoration,molding,corrosion resistance,superior workability,durability and weather resistance.

2:Quick Details of the Pre-Painted Galvanized/Aluzinc Steel Coil

Standard | ASTM ,EN,JIS | Grade: | CS,DX51D+Z,CGCC | Thickness | 0.16mm-1.5mm |

Place of Origin | China(Mainland) | Brand Name | Type | Steel Coil | |

Technique | Galvanized/Aluzinc | Surface | Coated | Application | Roof panel |

Width | 900mm-1250mm | Length | Coils | Zinc Coating | 30g/m2-275g/m2 |

Paint | Standard PE,PVDF,PU | Color | RAL Scale | Coil Weight | 3mt-7mt |

3:Packaging & Delivery

Packing: Export Standard Packing (full wrapped with anti-damped paper inside, iron sheet wrapped outside, and bundled by iron strips)

Delivery:30-45 Days

Detail Images:

Size can be customized

Financial support with max 180 days unsance L/C

Prime quanlity, competitive price

Fast delivery time.

4:PPGI / GI Steel Sheet

1) AVAILABLE DESIGNATION OF PPGI/PPGL Prepainted Galvanized/Aluzinc Steel Coils

Quality | Q/BQB 440-2003 | JIS G3312-1994 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

(BASE PLATE) | ||||

Commercial Steel | TDC51D | CGCC | DX51D+Z/AZ | CS Type A/B/C |

Forming Steel | (TSt01,TSt02,TSt03) | CGCD1 | FS Type A, Type B | |

Drawing | TDC52D /TDC53D | - | DX52D+Z/AZ | DDS TYPE A/C |

Steel | DX53D+Z/AZ | |||

Structural | TS280GD(TStE28) | CGC400 | S280D+Z/AZ | SS275 |

Steel | TS350GD(TStE34) | CGC440 | S350D+Z/AZ | SS340 Class1 |

2) OUR SPECIFICATION OFPPGI/PPGL (Prepainted Galvanized/Aluzinc Steel Coils)

Thickness | Width | Length of plate | Inner diameter of coil | |

0.16-1.2mm | 800/914/1000/1200/1219/1250mm | 1000-6000mm | 508mm/610mm |

Coated Mass OF PPGI/PPGL (Prepainted Galvanized/GalvalumeSteel Coils) :

Base plate | Available Coated Mass(g/m^2) |

Galvanized Steel | 80, 100, 120, 160, 180, 200, 275 |

Galvalume Steel | 50, 70, 150 ect. |

Available Painting OF PPGI/PPGL (Prepainted Galvanized/GalvalumeSteel Coils) :

Category of Painting | Item | Code | |

Polyester | PE | ||

High-durability polyester | HDP | ||

Silicon modified polyesters | SMP | ||

Polyvinylidene fluoride | PVDF | ||

Easy-Cleaning | — | ||

Painting Thickness | Top side: 20+5microns; | ||

Bottom side: 5~7microns. | |||

Color System | Produce according to RAL Color System or as per buyer’s color sample. | ||

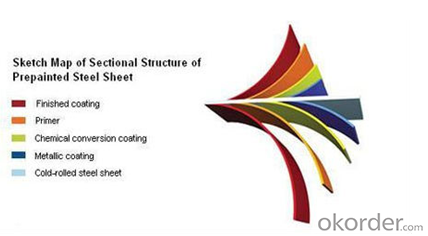

Painting structure | Top surface | Bottom surface | |

Primer coating | No coating | 1/0 | |

Primer coating | Primer coating | 1/1 | |

Primer coating + Finish coating | No coating | 2/0 | |

Primer coating + Finish coating | Primer coating or single back coating | 2/1 | |

Primer coating + Finish coating | Primer coating + Finish back coating | 2/2 | |

Note: Protect film available

3) APPLICATION OF PPGI/PPGL (Prepainted Galvanized/GalvalumeSteel Coils)

Construction | Outside | Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth |

Inside | Door, doorcase, light steel roof structure, folding screen, elevator, stairway, vent gutter | |

Electrical appliance | Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker | |

Furniture | Central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf | |

Carrying trade | Exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board | |

Others | Writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment | |

- Q: What are the different types of corrosion protection methods used for steel coils?

- There are several types of corrosion protection methods used for steel coils, including galvanization, painting, powder coating, and chemical treatments. Galvanization involves applying a layer of zinc to the steel surface to provide a barrier against corrosion. Painting and powder coating involve applying a protective layer of paint or powder to the steel, which acts as a barrier against moisture and other corrosive elements. Chemical treatments, such as phosphating or chromating, create a protective layer on the steel surface, preventing corrosion. These methods are used to ensure the longevity and durability of steel coils when exposed to harsh environmental conditions.

- Q: What is the thickness of a steel coil?

- The thickness of a steel coil can vary depending on the specific requirements and application. Typically, the thickness of a steel coil can range from a few millimeters to several centimeters.

- Q: What are the factors influencing the price of steel coils?

- The factors influencing the price of steel coils include the cost of raw materials, such as iron ore and coal, as well as energy prices, transportation costs, labor wages, and market demand. Additionally, exchange rates, trade policies, government regulations, and global economic conditions can also impact steel coil prices.

- Q: How are steel coils coated for corrosion resistance?

- Steel coils are typically coated for corrosion resistance using various methods such as hot-dip galvanizing, electroplating, or applying a protective layer of paint or powder coating.

- Q: Myself, iam Working In a Steel Fabrication Company. I completed my Engineering in 2006 and immediately recruited in this company in Oman. My company is Steel Fabrication company .So as i am new to this field, i just need some basic knowledge regarding this Steel Fabrication.Waiting for ur early reply.

- Your question covers a VERY broad area. This link should help you out, you will still have numerous other places you can look but this will cover your basics.

- Q: How are steel coils used in the production of scaffolding?

- Steel coils are essential in the production of scaffolding as they serve as a primary raw material for manufacturing various components of scaffolding systems. These coils are typically made from high-quality steel and are used to produce tubes, pipes, and other structural elements that form the framework of scaffolding. The steel coils are first processed through a series of manufacturing operations, such as cutting, shaping, and welding, to transform them into the required dimensions and shapes for scaffolding components. These components can include vertical and horizontal tubes, diagonal braces, and base plates, among others. The tubes and pipes formed from steel coils are the main structural elements used to build the framework of the scaffolding. They are used to create the vertical uprights or standards, as well as the horizontal ledgers and transoms that connect them. These components provide the strength, stability, and load-bearing capacity required for workers to safely access and work at elevated heights. Additionally, steel coils are also used to manufacture diagonal braces, which are crucial for reinforcing the scaffolding structure. These braces are installed diagonally between the vertical standards and provide additional support and stability to prevent the scaffolding from swaying or collapsing. Base plates, another essential component of scaffolding, are also produced from steel coils. These plates are used as a foundation for the scaffolding structure, providing a solid and stable base to distribute the weight and load evenly. They are typically placed at the bottom of each vertical standard to ensure stability and prevent sinking or sliding. In summary, steel coils are a fundamental material used in the production of scaffolding. They are transformed into tubes, pipes, braces, and base plates, which form the framework and provide the necessary strength, stability, and load-bearing capacity required for safe and efficient scaffolding systems.

- Q: What are the different grades of steel coils?

- There are several different grades of steel coils, including low carbon steel, medium carbon steel, high carbon steel, stainless steel, and galvanized steel. Each grade has its own unique properties and is used for specific applications based on factors such as strength, corrosion resistance, and formability.

- Q: for a roof spanning 14.4m x 8.4m on a residential house, is it better to use timber trusses or steel trusses? the priorities are; ease of construction, price, insulation (want to keep heat out, i am in a tropical country), durability, flexibility, minimal load on foundations.please help. thank you :-)

- How about another option - Steel Re-inforced Concrete Beams. Beam planks would span 8.4 metres but to keep the cost down have an I beam support at 4.2m. Concrete is great. It goes on quick, is sound proof, (very nice when it rains or for road traffic), can have gravel laid on top to act as a heat sink for winter sun and can be covered with normal roof steel if you want to hide it. Its also rust and borer free. While you would need good supports for the front and back, although with an I beam you can have a floating front, it is not much more than what is required for a wooden top. Design it right and your roof could be a future floor for the next addition.

- Q: Can steel coils be coated with barcodes?

- Yes, steel coils can be coated with barcodes. The barcode can be applied to the surface of the steel coil using various methods such as printing, engraving, or even attaching a barcode label. This allows for easy identification and tracking of the steel coils throughout the supply chain.

- Q: How are steel coils used in the production of appliances?

- Steel coils are used in the production of appliances as a primary material for constructing the various components, such as the outer shells, frames, and internal structures. The coils are processed and shaped into specific sizes and forms to meet the requirements of different appliances. Additionally, steel coils provide strength, durability, and a sleek appearance to the finished appliances.

Send your message to us

Color Coated Pre-Painted Steel Coil in High Quality in Blue

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords