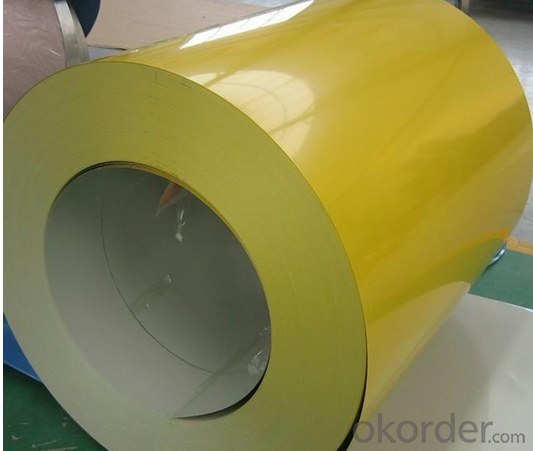

Color Coated GI/GL Steel Sheet or Coil in Yellow

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Color Coated GI/GL Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays workability, durability and weather resistance.

2.Main Features of the Color Coated GI/GL Steel Coil

• Excellent corrosion resistance

• Excellent weather resistance

• Capability of decoration, molding, corrosion resistance

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Color Coated GI/GL Steel Coil Images

4.Color Coated GI/GL Steel Coil Specification

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, green color.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Color Coated GI/GL Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Whats the difference in composition? When LTCS is used generally?Whats the temperature range, that these materials can be used? Is there any relation between Killed carbon steel, LTCS, stainless steel, carbon steel(normal)? How to categorise/classify these?Thankyou very much in advance..

- When exposed to elevated temperatures, quenched and tempered steels are more susceptible than normalized steels to permanent reduction in strength. This is especially true when exposure temperature begins to approach tempering temperature used when the parts were produced. In addition to losing strength, tempered steels also may experience reduced impact toughness after being exposed to long-term elevated temperatures. General belief is that this is the reason for LCC's reduced maximum allowable temperature limit of 345°C / 650°F in B16.34.

- Q: How are steel coils used in the production of pipes?

- Steel coils are used in the production of pipes by being unwound and then formed into the desired pipe shape through a series of bending, welding, and cutting processes. The steel coils provide the raw material for the pipes and ensure their strength and durability.

- Q: What is the weight of a standard steel coil?

- The weight of a standard steel coil can vary depending on its dimensions and thickness. However, a typical standard steel coil can weigh anywhere between 3 to 25 tons.

- Q: were iron age weapons made of steel?

- No, the iron age was just iron. It was smelted down in open fires where temperatures can vary. There was a problem of not always being able to cook out all the impurities from the ore, which led to inconsistent strengths in finished products. People first discovered the properties and advantages of steel when charcoal (carbon) was added to smelted iron. I don't know when the first steel was made. But it must have been a more expensive process because it didn't appear in household products until around 1800. But I'm not sure on that.

- Q: What are the different methods of uncoiling steel coils?

- Uncoiling steel coils can be done in several ways, depending on the specific requirements and available equipment. Some commonly used methods are: 1. Manual uncoiling: This method involves manually unwinding the coil using a bar or rod inserted through the inner diameter. It is suitable for smaller coils or when other methods are not accessible. 2. Mandrel uncoiling: A mandrel, a cylindrical tool, supports the inner diameter of the coil and enables free rotation. The coil is placed on the mandrel and rotated to unwind the steel. 3. Decoiler machine uncoiling: Designed specifically for uncoiling steel coils, these machines consist of a mandrel or drum to hold the coil. They also include a motorized mechanism to control the speed of unwinding. Decoilers are suitable for larger and heavier coils, making them ideal for industrial applications. 4. Straightener-feeder uncoiling: This method is utilized when the steel coil needs to be straightened and fed into a production line simultaneously. The coil passes through straightening rollers to remove any curvature before being fed into the subsequent processing equipment. 5. Recoiler uncoiling: Recoilers are used when the steel coil needs to be rewound into a new coil. The original coil is uncoiled using one of the previously mentioned methods, and then the steel is rewound onto a new mandrel or drum to create a smaller coil. It is important to consider factors such as the size and weight of the coil, desired level of automation, and specific production requirements when choosing an uncoiling method.

- Q: i want to know if i should buy a set of acrylic tapers or steel. they r close in cost so it's not a money factor i want to know which work better and if there is a downside to either. thanks!

- It relies upon on your physique and what you desire. in case you physique is allergic to a minimum of one in all them you may would desire to chosen for yet another one. If this is not any longer allergic to any, than you need to use in spite of you like the main, in simple terms attempt the two.

- Q: How do steel coil manufacturers ensure fair pricing?

- Various measures are taken by steel coil manufacturers to ensure fair pricing. To begin with, extensive market research is conducted to understand the current trends in the industry, the dynamics of supply and demand, and the pricing strategies of competitors. This information helps them determine a pricing strategy that is both competitive and fair, in line with market standards. In addition, the cost of raw materials, production, and operational expenses are carefully considered in order to establish a reasonable base price. The manufacturers also take into account economies of scale, as larger production volumes can result in lower costs per unit. Furthermore, steel coil manufacturers often establish long-term partnerships with suppliers to guarantee a stable and consistent supply of raw materials at fair prices. This allows them to maintain a reasonable cost structure and minimize fluctuations in pricing. Moreover, these manufacturers prioritize transparency in pricing by providing detailed quotations that break down the cost components. This enables customers to understand the factors contributing to the final price and ensures fairness in the pricing process. To further promote fairness, steel coil manufacturers take into account the specific requirements of each customer. They may offer customized pricing based on factors such as order volume, delivery timelines, and value-added services. This approach ensures that each customer receives a price that is tailored to their unique needs and requirements. Overall, steel coil manufacturers employ market research, cost considerations, transparent pricing practices, and customized pricing options to ensure fair pricing. Their goal is to create a pricing environment that is fair and mutually beneficial for both themselves and their customers.

- Q: Why are steel saucepans and tea kettles covered with copper on the outside and the bottom? what r the goals of having high-quality pans that are thick and tea kettles that are thin walled?

- Stainless steel is less conductive than copper. However, steel will retain heat longer and thus be distributed more evenly. (hence the thick bottoms, but also for balance). Copper on tea kettles is ideal to bring water up to a boil rapidly but since your not really cooking food, temperature distribution or control doesn't really matter. Now if your cooking sensitive food, then it does matter. For example, the use of a double boiler is preferred for chocolates. Temperature and distribution is critical. As far as relatively inexpensive copper clad pots and pans such as Revereware? Well, I don't see a difference but perhaps they did some testing.

- Q: What are the common methods of welding steel coils?

- The common methods of welding steel coils include shielded metal arc welding (SMAW), gas metal arc welding (GMAW), flux-cored arc welding (FCAW), and submerged arc welding (SAW).

- Q: Can one assume that stainless steel that can be hardened is magnetic?

- actually stain less steel is mainlly three first one is austenitic, 2nd one is ferritic, and 3rd is martensitic. These three types of steels are identified by their microstructure or predominant crystal phase. Austenitic. Austenitic steels have austenite as their primary phase (face centered cubic crystal). These are alloys containing chromium and nickel (sometimes manganese and nitrogen), structured around the Type 302 composition of iron, 18% chromium, and 8% nickel. Austenitic steels are not magnetic and not hardenable by heat treatment. The most familiar stainless steel is 304 containing 18-20% chromium and 8-10% nickel. Ferritic. Ferritic steels have ferrite (body centered cubic crystal) as their main phase. These steels contain iron and chromium. Ferritic steel is somewhat magnetic, less ductile than austenitic steel, and is not hardenable by heat treatment. Martensitic. Martensitic steels have orthorhombic martensite as their main phase. Martensitic steels are low carbon steels. They are magnetic, and may be tempered and hardened. Martensite gives steel great hardness, but it also reduces its toughness and makes it brittle. If you ran around the house with a magnet, checking on the items you know are stainless steel, you would probably find that cookware and flatware are not magnetic, but cutlery might be slightly magnetic.

Send your message to us

Color Coated GI/GL Steel Sheet or Coil in Yellow

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords