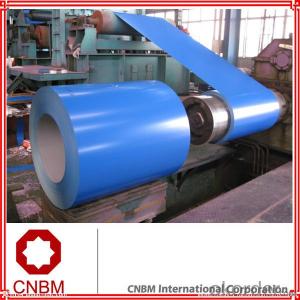

Color coated galvanized steel rolled coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 36 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Size | Thickness | 0.18-2 mm ,all available . |

Width | 40—1250mm, Steel Strips; 600—1250mm,Steel Sheets. | |

Length | Coil:Ususl weight of coil is 3-8tons Sheet:600-11000mm ,all are available. | |

Standard | AISI,ASTM,GB,JIS,Etc | |

Material | DX51D/52D/53D ;DC01/02/03 | |

MOQ | 20 Tons For Each Size And Each Color | |

Paint Specification | 1. Thickness: ≥20μm 2. Pencil Hardness: 2H 3. 60° specular glossiness of coating: >60 4. 180°bend: ≤3T 5. Impact: ≥9J 6. Salt Fog Resistant: ≥500h 7. Color difference:<0.8δe< span=""> | |

Coil Info | Coil ID | 508/610 mm |

Coil Weight | 3-8 Tons For Each Coil/Sheet | |

Coating (Zinc&Color)

1.Zinc Coating: As usual ,the zinc coating is 50-60g/m2 ,The range will be 40-275g/m2 .

2.Color: Done as the international RAL color chart ,and can also done as customers' color sample .

3.Painting: Front Painting:15-25 μm

Back Painting:5-10 μm

Features of Prepainted Steel Coil :

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.

- Q: How are steel coils used in the production of aerospace parts?

- Steel coils are used in the production of aerospace parts as they provide a reliable and durable material for manufacturing various components such as engine parts, structural beams, and landing gear. The coils are first processed and shaped into specific forms and sizes, then undergo further fabrication processes like cutting, welding, and machining to create the desired aerospace parts. The high strength and corrosion resistance of steel make it an ideal choice for ensuring the safety and performance of aerospace components.

- Q: Can cold rolled galvanized steel coils be acid washed after oxidation?

- If it has been galvanized, it can not be pickled, and if it is pickled, it may corrode the zinc layer

- Q: i was giving this old knive. the knife part is stainless steel and has a couple rust spots but im not sure that the handle is (i think stainless) but it has this un smooth surface i dont think its rust because its not brown. would rubbing alcohol help clean it?

- You can also try Barkeepers Friend.

- Q: What are the environmental considerations of using steel coils?

- There are several environmental considerations associated with using steel coils. Firstly, the production of steel coils requires a significant amount of energy and raw materials, which can contribute to greenhouse gas emissions and environmental degradation. Additionally, the extraction and processing of iron ore for steel production can have negative impacts on land, water, and air quality. Moreover, the transportation of steel coils, especially over long distances, can result in emissions from vehicles and contribute to pollution. Lastly, the disposal of steel coils at the end of their lifecycle poses challenges as they can be difficult to recycle and may end up in landfills, further contributing to waste accumulation. Overall, the environmental implications of using steel coils highlight the need for sustainable practices in their production, transportation, and disposal.

- Q: Can steel coils be bent or shaped?

- Yes, steel coils can be bent or shaped due to their flexibility and malleability.

- Q: How does stainless steel soap work? I have read the detailed explanation on Wikipedia, but their desciption seems skeptical on the actual chemical process that may take place from using such an item. Is there an actual scientific explanation to how stainless steel soap is able to clean your hands, when it is only a piece of metal?

- Many metals have germicidal qualities. Silver is the strongest germicide of the metals, but a sterling silver bar of soap would be expensive and it would tarnish. The tarnish would actually not affect the silver's ability to kill bacteria, but it would look bad and the tarnish would turn your hands black, so people wouldn't want to use it. Many people even take silver internally in the form of Colloidal Silver, but Colloidal Silver is very controversial. Yes, it kills many bacteria, but it can also cause a person's skin to permanently turn blue...a condition called Argyria. Brass actually is a better germicide than stainless steel...but again this is a cosmetic problem. Brass tarnishes, so people wouldn't want to use it. Stainless steel is actually a very weak germicide, but even steel has some ability to kill germs. Stainless steel also removes fish odor. My son has a stainless steel bar that he takes along when he fishes to remove the fish smell from his hands. There's nothing magical about the bar...a stainless steel spatula would would just as well, but the bar is more convenient to carry. I'm not sure if this is scientific enough or not. -

- Q: What are the different methods of edge camber correction for steel coils?

- There are several methods used for edge camber correction in steel coils, depending on the specific requirements and equipment available. Some of the common methods include: 1. Mechanical Edge Trimming: This method involves trimming the edges of the coil using mechanical tools such as shears or slitters. It helps to remove excess material and correct the camber. This method is often used for smaller coils or when the camber is minimal. 2. Tension Leveling: Tension leveling is a process where the coil is passed through a series of adjustable rollers under tension. The tension helps to elongate the steel and reduce the camber. This method is effective for correcting moderate camber and is commonly used for larger coils. 3. Roller Leveling: Roller leveling is similar to tension leveling, but instead of adjustable rollers, the coil is passed through a series of fixed rollers. These rollers exert pressure on the steel to flatten it and correct the edge camber. This method is often used for thicker and heavier coils. 4. Heat Straightening: Heat straightening involves applying controlled heat to the edges of the coil to soften the steel. Once the steel becomes malleable, external force is applied to straighten the edges. This method is suitable for correcting severe edge camber but requires specialized equipment and expertise. 5. Combination Methods: In some cases, a combination of different methods may be used to achieve the desired edge camber correction. For example, mechanical edge trimming may be followed by tension leveling or roller leveling to further straighten the edges. It is worth mentioning that the choice of method depends on various factors such as the severity of camber, coil dimensions, material properties, and available equipment. It is essential to evaluate these factors and consult with experts to determine the most suitable method for edge camber correction in steel coils.

- Q: What are the different types of steel coil surface protection methods?

- There are several types of steel coil surface protection methods, including oiling, painting, galvanizing, and applying protective films. These methods help prevent corrosion, rusting, and damage to the steel surface during storage, transportation, and processing.

- Q: What are the best types of steel for swords

- The okorder /

- Q: What are the common applications of hot-rolled steel coils?

- Hot-rolled steel coils are widely used in various industries due to their unique characteristics and versatility. Some of the common applications of hot-rolled steel coils include: 1. Automotive industry: Hot-rolled steel coils are extensively used in the automotive sector for manufacturing various components like frames, doors, hoods, wheels, and chassis. The high strength and formability of hot-rolled steel make it an ideal choice for producing durable and lightweight automotive parts. 2. Construction sector: Hot-rolled steel coils are widely used in construction projects for manufacturing structural components like beams, columns, and trusses. The high strength and ductility of hot-rolled steel make it suitable for withstanding heavy loads and providing structural stability. 3. Manufacturing industry: Hot-rolled steel coils find applications in the manufacturing sector for producing a wide range of products including machinery parts, pipes, tubes, and equipment. The excellent machinability and weldability of hot-rolled steel allow for easy fabrication and customization according to specific manufacturing requirements. 4. Energy sector: Hot-rolled steel coils are used in the energy sector for manufacturing pipelines, tanks, and other infrastructure required for oil and gas exploration, transmission, and storage. The corrosion resistance and strength of hot-rolled steel make it a preferred choice for such applications. 5. Appliances and furniture industry: Hot-rolled steel coils are used in the manufacturing of appliances like refrigerators, ovens, and washing machines, as well as for producing furniture components like frames and supports. The aesthetic appeal, durability, and cost-effectiveness of hot-rolled steel make it a popular choice in these industries. 6. Shipbuilding industry: Hot-rolled steel coils are extensively used in the shipbuilding sector for constructing various components like hulls, decks, and bulkheads. The high tensile strength and corrosion resistance of hot-rolled steel ensure the durability and longevity of ships in harsh marine environments. 7. Infrastructure and bridge construction: Hot-rolled steel coils are used in the construction of bridges, highways, and other infrastructure projects. The high strength and load-bearing capacity of hot-rolled steel make it suitable for supporting heavy traffic and withstanding dynamic loads. In summary, hot-rolled steel coils find applications in various industries including automotive, construction, manufacturing, energy, appliances and furniture, shipbuilding, and infrastructure. The unique properties of hot-rolled steel, such as high strength, formability, and versatility, make it an indispensable material for a wide range of applications.

Send your message to us

Color coated galvanized steel rolled coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 36 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords