Cold Rolled Galvanized Steel Coils/Sheets from China CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

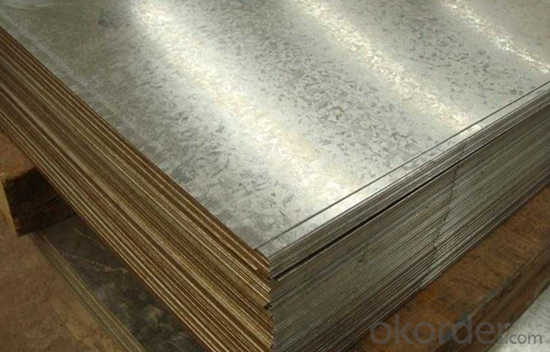

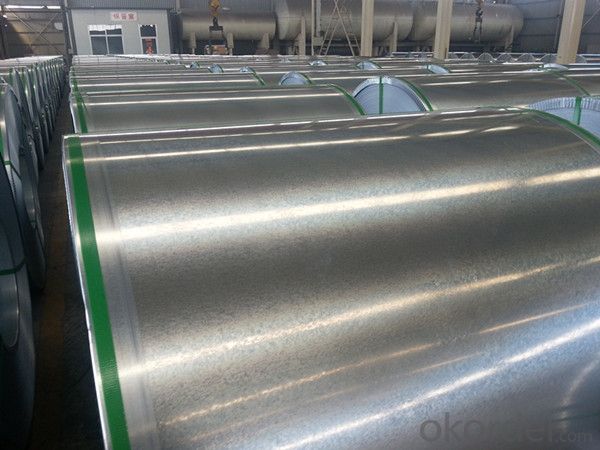

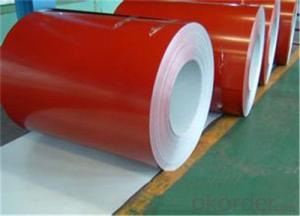

Product Description:

OKorder is offering high quality Cold rolled Hot Dip Galvanized Steel Coil at great prices with worldwide shipping. Our supplier is a world-class manufacturer of galvanized steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Cold rolled Hot Dip Galvanized Steel Coil is ideal for fabricating and manufacturing applications.

Product Advantages:

OKorder's Galvanized Steel Coil is durable, boasts high stiffness and load-bearing qualities, and is recyclable.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Coil ID: 508mm

Coil OD: 900-1500 mm

Grade: DX51D+Z

Coating: 30 – 180g/m² (both sides)

Dimensions:

Thickness: 0.2mm – 1.0mm

Width: 600mm, 914mm, 1000mm, 1220mm, 1250mm

Coil Weight: 4 – 6mt

Length: 6m, 9m, 12m

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Q6: What is the difference between galvanized steel and Galvalume steel?

A6: Galvanized steel is metallic coated with Zinc in various coating weights. Minimum recommended for painted metal roofs is G90. Galvalume is a zinc and aluminum coated steel that becomes an alloy and is recommended in either painted or bare applications with a minimum coating weight of AZ50. Galvalume has an excellent performance life in bare exposures. Hence if you are using a bare panel use Galvalume and if painted use either.

Images:

- Q: How are steel coils used in the packaging industry?

- Steel coils are used in the packaging industry to create durable and sturdy packaging materials, such as metal strapping and steel bands. These coils are commonly used to secure and protect heavy or bulky items during transportation, ensuring that the packaging remains intact and resistant to damage.

- Q: hello friends, I have some old 7.62x54r on stripper clips its nasty gunk on it can i use steel wool to glean it and still have it fire safely?

- You could, but if you have access to a vibrating case tumbler, it would work much better. I just tumbled a batch of 1,000 of tarnished and dirty Romanian 7.62X25 and it now looks like brand new commercial ammo.

- Q: Can steel coils be customized in terms of size and shape?

- Yes, steel coils can be customized in terms of both size and shape to meet specific requirements and applications.

- Q: How are steel coils used in the manufacturing of agricultural silos?

- Steel coils are used in the manufacturing of agricultural silos as they are rolled into large cylindrical shapes to form the outer structure of the silo. These coils provide strength, durability, and resistance to external elements, ensuring the silo can withstand the weight of the stored agricultural products and protect them from moisture and pests.

- Q: Several reading methods of steel tape measure

- Indirect reading methodIn some parts of the steel tape can not be used directly, can use the ruler or ruler, the zero alignment measurement, ruler and measurement direction; steel tape measure distance to a whole scale ruler or ruler, with more than a long reading amount. (3).Some errors in measuring steel tape

- Q: What are the different grades of steel used for coils?

- The different grades of steel used for coils vary depending on the specific requirements and applications. Some common grades include low-carbon steel (e.g., ASTM A36), medium-carbon steel (e.g., ASTM A516), high-strength low-alloy (HSLA) steel (e.g., ASTM A572), and stainless steel (e.g., 304 or 316). Each grade offers distinct properties such as strength, corrosion resistance, and formability, enabling manufacturers to choose the appropriate one based on their needs.

- Q: What are the different methods of heat treatment for steel coils?

- There are several methods of heat treatment for steel coils, including annealing, quenching, tempering, normalizing, and stress relieving. Each method involves heating the steel to a specific temperature and then cooling it in a controlled manner to achieve desired properties such as increased hardness, improved strength, or reduced residual stresses. These methods can be tailored based on the specific requirements of the steel and the intended application.

- Q: How are steel coils used in the manufacturing of consumer goods?

- Steel coils are used in the manufacturing of consumer goods as a primary material for various products. The coils are typically processed and transformed into different shapes, such as sheets, strips, or wires, which are then used to create a wide range of items like appliances, furniture, automotive components, and construction materials. The durability and strength of steel make it an ideal choice for consumer goods, ensuring long-lasting and reliable products for consumers.

- Q: For robotics homework, I need to find out how steel is galvanized and why. I researched a little bit, and I'm not sure I grasp the entire concept. Simple words would be helpful :) Thank you!!!

- Steel can be galvinised by electroplating process. Galvinising means providing a zinc coating on steel surface. It protects the material from rusting and loosing the shinining.

- Q: How are steel coils used in automotive manufacturing?

- Steel coils are used in automotive manufacturing as the primary material for forming various components such as body panels, frames, and suspension parts. These coils are processed through specialized machinery and undergo shaping, cutting, and welding to create the desired parts. The durability, strength, and versatility of steel make it an ideal choice for automotive applications, ensuring safety and structural integrity in vehicles.

Send your message to us

Cold Rolled Galvanized Steel Coils/Sheets from China CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords