cold rolled steel sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | seaworthy packing or as per customer's require |

| Delivery Detail: | 30days |

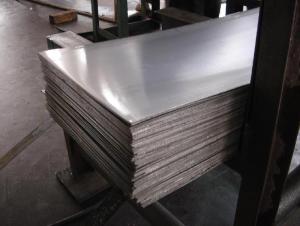

Specifications

Manufacture of CRC

SPCC/ST12/DC01/Q195/Q195L

1000,000 tons per year Stable Supply

Delivery on time

- Q: Can steel sheets be used for manufacturing shipping pallets?

- Yes, steel sheets can be used for manufacturing shipping pallets. Steel is a strong and durable material that can withstand heavy loads, making it suitable for the construction of pallets. Steel sheets can be welded or bolted together to create a sturdy and reliable pallet structure. Additionally, steel pallets have the advantage of being resistant to moisture, pests, and fire, which can be important considerations for certain industries or applications. However, it is worth noting that steel pallets are generally more expensive than other materials such as wood or plastic, so the choice of using steel sheets for manufacturing shipping pallets would depend on specific requirements, budget, and intended use.

- Q: What are the different jointing methods for steel sheets?

- There are several different jointing methods for steel sheets, including welding, riveting, adhesive bonding, and mechanical fastening.

- Q: How are steel sheets transported and stored?

- Steel sheets are typically transported and stored using various methods. For transportation, they are loaded onto trucks, trains, or ships, either in bundles or stacked on pallets. To prevent damage during transit, they may be secured with straps or placed in containers. When it comes to storage, steel sheets are often stored outdoors in designated areas or warehouses. They are stacked vertically or horizontally, depending on their size and weight, using forklifts or cranes. To prevent corrosion, they are usually covered with protective coatings or stored in a climate-controlled environment. Additionally, they may be organized based on size, type, or customer orders for easy accessibility and inventory management.

- Q: Can steel sheets be used for furniture manufacturing?

- Certainly, furniture manufacturing can utilize steel sheets. Steel, being a versatile and durable material, lends itself well to shaping and forming into various furniture components, including table legs, frames, and shelves. The strength, stability, and sleek appearance of steel sheets make them a commonly chosen option for producing modern and industrial-style furniture. Moreover, steel offers easy customization through welding, bending, or cutting, enabling the creation of personalized furniture designs. By incorporating steel sheets, furniture manufacturers gain advantages such as resistance to corrosion, fire, and pests. Consequently, steel sheets have become a favored choice among furniture manufacturers aiming to craft contemporary, sturdy, and enduring furniture pieces.

- Q: What is the tensile strength of the steel sheets?

- The tensile strength of steel sheets can vary depending on the specific grade and thickness of the steel. Generally, steel sheets have a tensile strength ranging from 370 to 1,500 megapascals (MPa). However, it is important to note that different types of steel sheets have different tensile strength values. For example, low carbon steel sheets typically have a tensile strength of around 370 to 550 MPa, while high-strength low alloy (HSLA) steel sheets can have tensile strengths ranging from 450 to 1,200 MPa. Additionally, the thickness of the steel sheets can also affect their tensile strength, with thicker sheets generally having higher tensile strength values. Therefore, it is crucial to consult the specifications provided by the manufacturer or supplier of the steel sheets to determine the precise tensile strength for a particular grade and thickness.

- Q: What is the average lifespan of a painted steel sheet?

- The lifespan of a painted steel sheet can differ based on several factors, including the paint quality, exposure to the environment, and maintenance. However, a well-maintained painted steel sheet typically lasts between 20 to 50 years. It should be emphasized that regular inspections, cleaning, and touch-up painting contribute to extending the sheet's lifespan. Furthermore, the durability of both the paint and the sheet can be greatly affected by exposure to severe weather, extreme temperatures, or corrosive environments.

- Q: What is the maximum size of the steel sheets available?

- The specific supplier or manufacturer determines the maximum size of available steel sheets, which can vary. Generally, steel sheets come in a variety of sizes, ranging from 36 inches to 72 inches in width, and 96 inches to 240 inches in length. However, it should be noted that these dimensions may differ depending on the supplier's capabilities and the customer's specific requirements. Therefore, it is recommended to directly contact a supplier or manufacturer for information regarding the largest size of steel sheets they can offer.

- Q: How are steel sheets measured and sized?

- Steel sheets are measured and sized based on their thickness, width, and length. The thickness is usually measured in gauge or millimeters, while the width and length are measured in inches or millimeters. The dimensions are typically standardized and can vary depending on the specific application or industry requirement.

- Q: Are steel sheets suitable for cold storage applications?

- Yes, steel sheets are suitable for cold storage applications. Steel is known for its durability, strength, and resistance to extreme temperatures, making it an ideal material for cold storage facilities. It helps maintain a consistent temperature, prevents condensation, and provides excellent insulation, ensuring the quality and freshness of stored goods. Additionally, steel sheets are easy to clean, maintain, and can withstand heavy loads, making them a reliable choice for cold storage applications.

- Q: Are steel sheets available in textured finishes?

- Yes, steel sheets are available in textured finishes. Textured finishes can be achieved through various processes such as embossing, etching, or brushing. These techniques create patterns or textures on the surface of the steel sheet, giving it a unique and visually appealing appearance. These textured finishes not only enhance the aesthetic appeal of the steel sheet but also provide functional benefits like improved grip, reduced glare, or increased durability. Different types of textures can be applied to steel sheets to suit different applications and design preferences.

Send your message to us

cold rolled steel sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords