Cold Rolled Steel of Every Size and Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Cold Rolled Steel Description:

The raw material of cold rolled steel coil/sheet is high quality hot rolled product, and after pickling continuous rolling, degreasing, annealing,skin pass,slitting and cut to length line etc. Along with it many kinds of new technology and new process of global cold rolling production have been applied. Therefore the quality of the goods could be guaranteed. The product is widely used in outdoor and interior decoration, furnishing manufacturing, home appliance, automobile etc.

2.Main Features of the Cold Rolled Steel:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

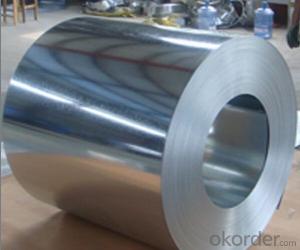

3.Cold Rolled Steel Images

4.Cold Rolled Steel Specification

Standard:AISI,ASTM,DIN,GB,JIS,JIS G3302 ASTM 653M EN10142

Grade: Q195~Q345

Thickness: 0.16mm~1.5mm,0.16-1.5mm

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Cold Rolled Steel

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: What is the lifespan of steel coils?

- The lifespan of steel coils can vary depending on various factors such as the quality of the steel, its usage, maintenance, and environmental conditions. However, with proper care and maintenance, steel coils can typically last for several decades.

- Q: How are steel coils used in the manufacturing of construction scaffolding?

- Steel coils are used in the manufacturing of construction scaffolding as they provide the necessary strength and durability required for the structures. These coils are generally processed and shaped into various components, such as pipes, tubes, and frames, which form the main structure of the scaffolding. The high tensile strength of steel coils ensures that the scaffolding can support heavy loads and provide a safe working platform for workers at construction sites.

- Q: Is it just because brass is reloadable? But what makes it reloadable? What does brass bring to the equation that the steel cased ammo can't do?

- Brass is slightly softer than annealed steel. Both can be reloaded, once or maybe even twice. But STEEL has a tendency to WORK HARDEN, becoming brittle. Which is why it's used for tools and other applications where work hardening is a plus. It's actually designed to do that. Brass does not work harden, because it is a different sort of metal. That's the main reason.

- Q: i cant find this stuff about steel:conductivitystrengthcorrosion resistancecommon applicationsif you know of any interesting facts, i could use those 2!thanx!

- go okorder and search for steel.......

- Q: i mean cor ten steel( rusted)

- If the steel is true Cor Ten steel, it does not require waxing. Cor Ten is a steel designed to rust slowly over time ... then the rust acts as a natural barrier to prevent further rust. Check out the United States Steel building in downtown Pittsburgh, PA ... its nickname is The Rusty Nail.

- Q: it has 2 be 20 inches overall, and 2and1/2 inches wide and .25 or more inches thick... im thinking truck steel but im not sure thx

- I made mine from a power hack saw blade. Granted it isn;t a quarter inch thick but it sure works well. Used the tooth part for the blade edge, just ground off the teeth. I can use a hammer or a stone on he back side of the blade to chop through the bone when cleaning deer.

- Q: I want to save water $$, so I want to use frozen steel to cool my coke. possible or no?

- Wouldn't it be easier to stick your coke in the freezer?

- Q: How are steel coils used in the manufacturing of industrial mixers?

- Steel coils are used in the manufacturing of industrial mixers as they are typically used to construct the main body and structural components of the mixer. The coils are formed into the desired shape and size, providing strength, durability, and stability to the mixer, allowing it to withstand the rigorous mixing processes involved in industrial applications.

- Q: I'm assuming that brass is flexible, expands and then bounces back to it's original shape. But if aluminum and steel expand and don't contract wouldn't they cause guns to jam more often for example?

- Steel is magnetic, and can spark...Sparks are not good things around gun powder....CCI loads some pistol rounds with aluminum cases, but they are not re loadable, as the aluminum is so soft the primer pockets will wear out quickly..Aluminum, metallurgical, has a valence of +3, which means that moisture would cause electrolysis to set up between the steel primer cup and the aluminum case, which would pit the primer pocket...Steel is harder than brass, and would not uniformly expand on the firing sequence, and would be likely to rupture instead of expanding and sealing...Also, the hardness of steel would make resizing cases difficult, as steel needs to be heated before reshaping.......Hope this helps....

- Q: Theirs this two handed chinese sword on amazon with a forged combat steel blade and i was wandering if it means combat steel in the same sense that tempered carbon steel can be used?

- as has been said before it is a mystery steel that could mean anything honestly I am guessing closer to 1045 than the already mentioned 1095.... or just stainless steel of some variety tldr we all are telling the truth do not buy it

Send your message to us

Cold Rolled Steel of Every Size and Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords