Cold Rolled Steel Descriptions for Your needs

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Cold Rolled Steel Description:

The raw material of cold rolled steel coil/sheet is high quality hot rolled product, and after pickling continuous rolling, degreasing, annealing,skin pass,slitting and cut to length line etc. Along with it many kinds of new technology and new process of global cold rolling production have been applied. Therefore the quality of the goods could be guaranteed. The product is widely used in outdoor and interior decoration, furnishing manufacturing, home appliance, automobile etc.

2.Main Features of the Cold Rolled Steel:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

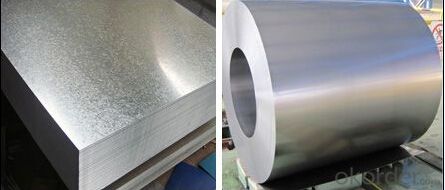

3.Cold Rolled Steel Images

4.Cold Rolled Steel Specification

Standard:AISI,ASTM,DIN,GB,JIS,JIS G3302 ASTM 653M EN10142

Grade: Q195~Q345

Thickness: 0.16mm~1.5mm,0.16-1.5mm

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Cold Rolled Steel

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: What are the common methods of preserving steel coils?

- Some common methods of preserving steel coils include applying protective coatings, such as oil or paint, to prevent corrosion and rust formation. Another method is using VCI (Vapor Corrosion Inhibitor) paper or film, which releases chemicals that prevent oxidation. Additionally, steel coils can be stored in climate-controlled environments or wrapped in moisture-resistant materials to minimize exposure to moisture and humidity, which can accelerate corrosion.

- Q: What are the factors affecting the strength of steel coils?

- The strength of steel coils can be influenced by several factors. These include the grade of steel used, the manufacturing process employed, the thickness and width of the coils, the quality of their surface, how they are stored and handled, and the environmental conditions they are exposed to. When choosing and using steel coils, it is crucial to take these factors into account to ensure that they meet the necessary strength requirements for their intended use.

- Q: Hello people.Me and the life mate have been working on a fantasy book together and we are currently in the process of outlining the cultures. The culture of our antagonists' is a sort of woodland tribal/celtic[ish] deal and they are very nature oriented. Being a detail freak and wanting to have some real world credibility in the story, I am trying to decide how they produce steel. I want steel to be an important part of the culture, but a thing that is in limited supply. I also do not want there to be a large amount of resources committeded to mining or processing iron ore for steel. So does anyone have any real world ideas explaining how the people can produce steel without using underground mining operations, large processing facilities, and without raping the land?All help and ideas are appreciated

- Well, steel is just modified iron, so you're going to have to start with acquiring the iron first. For that, you're most likely going to be using some sort of underground mining somewhere - either they do that themselves, or they purchase the iron elsewhere. Assuming you're not dealing with meteoric iron (which is possible, but pretty uncommon), or iron sands (not likely in a woodland area), then unless you're dealing with a rocky outcropping with iron veins out in the open, I'm pretty sure there needs to be somebody doing some digging. That said, it doesn't need to be a full raping of the land scenario. A couple of minor mines, some small-scale smelting operations, and somebody knowing the secret of making steel, and it could give you small amounts of steel without making an ecological disaster.

- Q: so i just bought a stainless steel bracelet.......and recently found out that stainless steel isnt actually stainless..........will turpentine ruin it

- real s/steel is nickel and chrome, however manufacturers of kitchenware, e.g s/teel cutlery use the cheaper version of nickel chrome and iron, that is why some s/steel products rust, so if you want to test any products carry asmall magnet and test the article

- Q: Can steel coils be bent or shaped?

- Yes, steel coils can be bent or shaped. Steel coils are highly flexible and can undergo various bending and shaping processes to achieve desired forms and configurations.

- Q: How are steel coils used in the production of doors and windows?

- The strength and versatility of steel coils make them crucial in the manufacturing process of doors and windows. Typically made from high-quality steel, these coils have various applications. To begin with, steel coils are utilized in the creation of door and window frames. When unrolled, they are cut into specific lengths to match the desired dimensions of the frame. The steel is then bent and shaped into the required design, ensuring durability and strength. Furthermore, the coils are employed in producing the panels or glass holders for doors and windows. The steel is cut and formed into the desired shape, and then either welded or attached to the frame. This guarantees a sturdy structure capable of withstanding the weight and pressure of the glass or panels. In addition, steel coils are also used for manufacturing hinges and other hardware components. By cutting and shaping the coils, the necessary parts are created, ensuring sufficient strength to support the movement and functionality of the doors and windows. Moreover, steel coils serve decorative purposes as well. They can undergo embossing or be coated with different finishes, enhancing the appearance of doors and windows. This vast range of design options enables manufacturers to create products that cater to various architectural styles and individual preferences. In essence, steel coils play a pivotal role in the production of doors and windows. From creating frames, panels, hinges, and hardware components to offering customization and aesthetic appeal, their importance cannot be overstated.

- Q: How are steel coils used in the production of roofing sheets?

- Steel coils are an essential component in the production of roofing sheets. These coils are typically made from high-quality steel, which is known for its durability, strength, and resistance to corrosion. They undergo a series of processes to transform them into roofing sheets. Firstly, the steel coils are loaded onto a machine called a decoiler, which unrolls the coils and feeds them into the production line. This machine ensures a continuous supply of steel for the manufacturing process. Next, the steel coils pass through a series of rollers, which shape the steel into the desired profile for the roofing sheets. These rollers can create various profiles, such as corrugated or standing seam, depending on the specific requirements of the roofing project. After the shaping process, the steel sheets are often coated with protective layers to enhance their durability. This coating can be in the form of zinc or other metallic alloys, known as galvanized or galvalume coatings, respectively. These coatings provide an additional layer of protection against rust and corrosion. Once the sheets are coated, they are typically cut to the desired length and width. This can be done using shearing machines or other cutting tools, ensuring that the roofing sheets are sized correctly for installation. Finally, the roofing sheets are packaged and prepared for distribution to construction sites. They are often bundled together and securely wrapped to protect them during transportation. In summary, steel coils are crucial in the production of roofing sheets. They undergo shaping, coating, cutting, and packaging processes to transform them into finished products ready for installation. The use of steel coils ensures that roofing sheets are strong, durable, and resistant to various environmental factors, making them a popular choice for roofing applications.

- Q: What are the different types of steel coil finishing tools?

- There are several types of steel coil finishing tools, including slitters, shears, levelers, and recoilers. These tools are used to cut, flatten, and rewind steel coils to achieve the desired shape and surface finish.

- Q: How are steel coils transported internationally?

- Typically, steel coils are shipped internationally by sea due to their heavy and bulky nature, which makes air transportation impractical. The most common method involves using specialized shipping containers called flatracks or open-top containers, which allow for easy loading and unloading onto vessels. Before being transported, the steel coils are typically securely strapped or banded together to prevent movement or damage during transit. Cranes or forklifts are then used to load the coils onto the flatracks or open-top containers. Careful placement and securing of the coils onto the containers ensure stability and prevent shifting during the journey. Once loaded, the containers are sealed and taken to the nearest port, where they are loaded onto cargo ships designed specifically for heavy and oversized cargo. These ships are equipped with specialized handling equipment like cranes and ramps to facilitate container handling. During the journey, the cargo ships adhere to predetermined shipping routes to reach the destination port. The duration of the journey depends on the distance between the origin and destination ports. Since steel coils are typically transported in large quantities, multiple containers may be loaded onto a single ship. Upon arrival at the destination port, cranes or ramps are used to unload the containers from the cargo ship. The steel coils are then carefully removed from the containers and transported to their final destination, which may involve further transportation by road or rail. Throughout the transportation process, it is crucial to adequately protect the steel coils from moisture, corrosion, and other potential damages. Special attention is given to handling and stowage to minimize the risk of structural damage or deformation. In conclusion, specialized shipping containers are utilized to transport steel coils internationally by sea. The coils are securely loaded onto flatracks or open-top containers and transported by cargo ships to the destination port. Proper handling and stowage techniques are employed to ensure the safe and secure transportation of the steel coils.

- Q: What is the difference between a steel strip and a coil? The steel strip is flat steel, and the steel coil is made of steel. Is that correct?

- A steel strip is also a coil, usually a narrow strip, also known as a steel strip. The volume is relatively wide. In addition, flat steel is usually hot-rolled out of long strip steel, fixed length 5 and 5.5,6 meters range, steel coil is Kaiping Chang 12501500, length 2.5 meters, 4 meters, 6 meters, ranging from steel plate

Send your message to us

Cold Rolled Steel Descriptions for Your needs

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords