Cold rolled steel channel offer free samples

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 63450 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

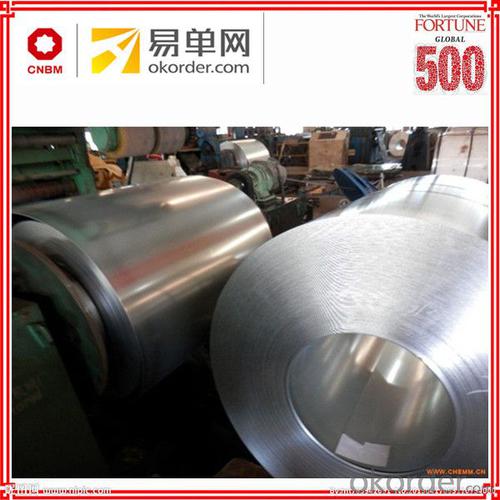

These cold rolled steel coil/sheet grades have excellent formability, which facilitates cold forming operations, and are ideal for deep drawing. Our range of steels for cold forming offer excellent forming performance, due to the low scattering of their chemical composition and their mechanical properties, which guarantees processing consistency.

It is suited to formation by bending or drawing, which enables complex parts to be produced in good repeatable conditions and intended for indoor use.

Cold Rolled Steel coil is a mill product made with a high degree of gauge accuracy and uniformity of physical characteristics. The smooth deoxidized matte finish gives an excellent base for paint, lacquer and enamel. Box annealing and absence of scale permit stamping and moderate drawing operations. Sheets bend flat on themselves without cracking. Oiling protects Surface against rust. The application of surface oil to cold rolled steel coil/sheet is intended to provide protection from corrosion ("rusting") during shipment and warehousing. Because cold rolled steel sheet is prone to rusting, standard practice is to apply a rust-preventative oil at the exit end of the temper mill (the last processing step).

Standard and Grade :

Cold rolled steel coils | ||||

JIS G3141-2005 | EN10130-2006 | ASTM A1008-12a | ||

Commercial quality | SPCC | DC01 | CS Type A/B/C | |

Drawing quality | SPCD | DC03 | DS Type A/B | |

Deep drawing quality | SPCE SPCF(non aging) | DC04 | DDS | |

Extra deep drawing quality | SPCG(non aging) | DC05/06 | EDDS | |

Application :

Automobile Industry, White Goods, Home Applicances, Oil & Air filters, semi product for coating with enamel or zinc,

construction & building sector, air-conditioning, furniture, radiators, tubes, profiles, mechanical construction, shelving,

containers, drums

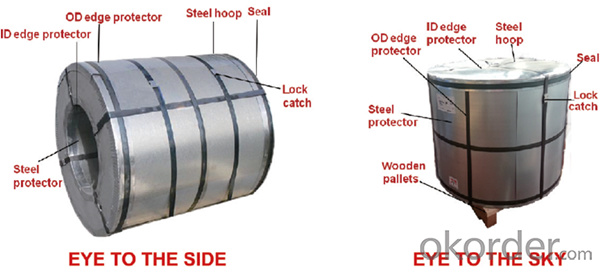

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. Can you offer OEM to me? What about MOQ?

Of course, we are a professional with OEM manufacturer for 9 years. the MOQ can be 50 ton/ order..

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

4.How Can I Get Some Sample?

We are honored to offer you free sample, but courier charges will be on your side.

- Q: How are steel coils inspected for surface cleanliness after processing?

- Steel coils are inspected for surface cleanliness after processing through various methods such as visual inspection, magnetic particle inspection, and fluorescent penetrant inspection. These techniques help identify any surface defects, contaminants, or impurities on the steel coils, ensuring their quality and suitability for further use or shipment.

- Q: How do steel coils contribute to the manufacturing of construction materials?

- The manufacturing of construction materials heavily relies on steel coils, as they serve as a flexible and dependable source of raw material. These coils, made from top-notch steel, are commonly used as a primary input in diverse construction processes. One of the key advantages of steel coils in construction material manufacturing lies in their adaptability to be shaped and formed into different products. These coils can be easily cut, bent, and molded, enabling the creation of a wide array of construction materials such as beams, pipes, and sheets. This flexibility empowers manufacturers to produce tailor-made construction components that fulfill specific project requirements. Moreover, steel coils provide construction materials with strength and durability. Steel is renowned for its exceptional tensile strength, making it an ideal choice for load-bearing structures and components. By employing steel coils, manufacturers can fabricate construction materials capable of withstanding heavy loads, extreme weather conditions, and other environmental factors, ensuring the longevity and safety of the final construction product. Additionally, steel coils offer consistency in both quality and performance. The manufacturing process of steel coils adheres to rigorous quality control measures, guaranteeing that the final product meets the necessary specifications. This uniformity in quality instills construction material manufacturers with the confidence to consistently produce reliable and high-performance products. Steel coils also play a role in enhancing the efficiency of construction material manufacturing. The availability of steel coils in large quantities and standardized dimensions allows for streamlined production processes. Manufacturers can optimize their operations by utilizing automated machinery and processes, reducing production time and costs, and increasing overall efficiency. In conclusion, steel coils are an indispensable component in the manufacturing of construction materials. Their versatility, strength, consistency, and efficiency make them the preferred choice for construction material manufacturers. By utilizing steel coils, manufacturers can create construction materials of superior quality and reliability, contributing to the safety, durability, and aesthetics of various construction projects.

- Q: I received a very nice set of stainless steel cookware as a wedding gift. While very pretty, Im finding them almost useless for cooking. Everything sticks, they're difficult to clean, and Im using my old non-stick pans instead. Should I simply leave the stainless out for decortive purposes, or are stainless steel pans better for some applications?

- This Site Might Help You. RE: Why should I use stainless steel cookware? I received a very nice set of stainless steel cookware as a wedding gift. While very pretty, Im finding them almost useless for cooking. Everything sticks, they're difficult to clean, and Im using my old non-stick pans instead. Should I simply leave the stainless out for decortive purposes, or...

- Q: What are the different types of steel coil slitting methods?

- There are three main types of steel coil slitting methods: rotary slitting, loop slitting, and oscillating slitting. Rotary slitting involves using a circular knife to cut the coil into smaller strips. Loop slitting involves creating a loop in the coil and then cutting it using a straight knife. Oscillating slitting involves using a reciprocating knife to make a back-and-forth motion while cutting the coil. These methods allow for precise and efficient slitting of steel coils into narrower strips.

- Q: What are the dimensions of steel coils used in the building materials industry?

- The dimensions of steel coils used in the building materials industry can vary depending on the specific application and requirements. However, common dimensions for steel coils used in this industry typically range from 0.5mm to 3mm in thickness and 600mm to 1500mm in width. The length of the coil can vary depending on the manufacturer and customer specifications. It is also important to note that the weight of the coil can vary, with typical weights ranging from a few hundred kilograms to several tonnes, depending on the size and thickness of the coil. Ultimately, the dimensions of steel coils in the building materials industry are determined by the specific needs and specifications of the construction projects they are intended for.

- Q: How are steel coils inspected for paint adhesion?

- Steel coils are inspected for paint adhesion through various methods such as visual examination, tape test, and cross-cut adhesion test. These tests involve visually inspecting the surface for any paint defects, applying adhesive tape to check if the paint adheres properly, and making cross-cuts to assess the adhesion strength.

- Q: Steel Strings on your guitar or nylons? Why?

- There is no OR about it. You CANNOT use steel strings on a nylon string guitar because the increased tension will actually warp the top of the guitar and eventually pull the bridge right off! (I have seen it happen several times!) Although it is possible to put nylon strings on a steel string guitar it is not recommended. Nylon strings do not have as much tension as a steel string guitar is designed for. Steel string guitar necks are actually designed with a bit of back bow to compensate for the high tension of steel strings. Nylon strings have a much lower tension which could cause the neck of a steel string to settle slightly, which could actually cause the strings to fret out. It is not common, but it does happen. So keep your guitars happy and only string them with the proper strings.

- Q: How are steel coils used in the construction of buildings?

- Steel coils are used in the construction of buildings primarily for their strength and durability. These coils are typically formed into beams, columns, and other structural components, providing a sturdy framework. Additionally, steel coils can be shaped into sheets or plates used for roofing, walls, and flooring, offering excellent resistance to weather and fire. Overall, steel coils play a crucial role in ensuring the stability and longevity of buildings.

- Q: i want a good modern carbon steel (not stainless) knife. trying to keep it under 50$ also nothing to gruesome just a small pocket knife. thank you

- Well, okorder /... They did make other folders in M2 steel, but the thing is those are out of production and the cost is very high. Spyderco made M4 steel folder knives, and so did Benchmade. Although,both are outside of 50$ budget. I guess Opinels are best option.

- Q: How are steel coils used in the manufacturing of wind turbines?

- Steel coils are used in the manufacturing of wind turbines to create various components such as the tower, nacelle, and rotor blades. The high-strength steel coils are shaped and welded to form the tower, providing the necessary structural support for the entire turbine. Additionally, the steel coils are used to fabricate the nacelle, which houses the generator and other critical components. Moreover, steel coils are used in the manufacturing of rotor blades, providing strength and stability to harness wind energy efficiently. Overall, steel coils play a crucial role in the construction of wind turbines, ensuring their durability and performance.

Send your message to us

Cold rolled steel channel offer free samples

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 63450 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords