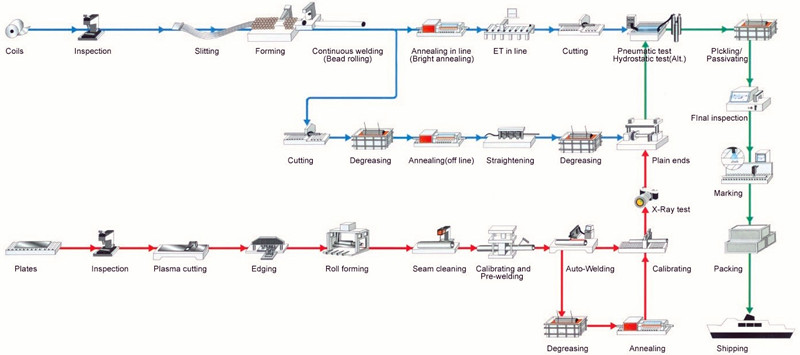

cold rolled stainless steel welded pipe

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

stainless steel pipe

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely used in light industry,heavy industry,daily necessities and the decoration industry.my company long term supply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube

Specifications

1.Specification:21.3*3.73mm or others

2.Surface:4k/6k//8k

3.Length:6m or as your requirement

A series of photos

A series of pictures

- Q: Can stainless steel pipes be used for cryogenic storage tanks?

- Yes, stainless steel pipes can be used for cryogenic storage tanks. Stainless steel is known for its excellent corrosion resistance, durability, and strength, which make it suitable for storing extremely cold liquids or gases. Cryogenic storage tanks are designed to store materials at very low temperatures, typically below -150 degrees Celsius. Stainless steel pipes are capable of withstanding these low temperatures without becoming brittle or losing their mechanical properties. Additionally, stainless steel has low thermal conductivity, which helps to minimize heat transfer and maintain the desired temperature inside the storage tank. Therefore, stainless steel pipes are commonly used in cryogenic storage tanks to ensure the safe and efficient storage of cryogenic materials.

- Q: Can stainless steel pipes be insulated with polyetherimide?

- Yes, stainless steel pipes can be insulated with polyetherimide. Polyetherimide is a high-performance thermoplastic material that can withstand high temperatures and is known for its excellent thermal insulation properties. It can be used as an effective insulation material for stainless steel pipes, providing thermal protection and preventing heat loss or gain.

- Q: What is the difference between seamless and ERW stainless steel pipes?

- Seamless stainless steel pipes are made by extruding a solid billet through a piercing rod to create a hollow tube, while ERW (Electric Resistance Welded) stainless steel pipes are formed by rolling a strip of steel into a tube and then welding the edges together using an electric current. The main difference is the manufacturing process, with seamless pipes having no welded seams, making them stronger and more suitable for high-pressure and high-temperature applications. On the other hand, ERW pipes are more cost-effective and commonly used for lower-pressure applications.

- Q: Are stainless steel pipes suitable for hot water applications?

- Yes, stainless steel pipes are highly suitable for hot water applications. Stainless steel has excellent corrosion resistance, high strength, and can withstand high temperatures, making it a reliable choice for carrying hot water. It is also hygienic and durable, making it a preferred material for applications where cleanliness and longevity are essential, such as in the plumbing industry.

- Q: What is the maximum pressure rating for stainless steel pipe fittings?

- There are several factors that contribute to the maximum pressure rating of stainless steel pipe fittings, including the material grade, size, and temperature. In general, stainless steel pipe fittings have the ability to handle high-pressure applications due to their strength and resistance to corrosion. The pressure rating of these fittings can vary greatly, ranging from 150 psi to as high as 10,000 psi, depending on the specific fitting and its intended use. To determine the maximum pressure rating for a particular stainless steel pipe fitting, it is important to refer to the manufacturer's documentation or industry standards such as ASME B16.11 or ASME B16.9. Additionally, when working with high-pressure systems, other factors such as the sealing method, compatibility with the conveyed fluid, and any necessary safety precautions must be taken into consideration.

- Q: What are the different types of stainless steel pipe end connections?

- There are several different types of stainless steel pipe end connections, each designed for specific applications and requirements. Some of the most common types include: 1. Threaded connections: This type of connection features threads on the inside or outside of the pipe end, allowing it to be screwed onto another threaded fitting or pipe. Threaded connections are typically used for low-pressure applications. 2. Socket-weld connections: In this type of connection, the pipe end is inserted into a socket or recess of a socket-weld fitting and then welded around the outside of the pipe. Socket-weld connections are suitable for high-pressure applications and are known for their strength and reliability. 3. Butt-weld connections: Butt-weld connections involve welding the pipe end directly to another pipe or fitting. They are commonly used in high-pressure and high-temperature applications. 4. Flanged connections: Flanged connections feature a flange on the pipe end, which is then bolted to a mating flange on another pipe or fitting. Flanged connections are used in applications requiring easy disassembly or where there is a need for frequent maintenance. 5. Compression connections: Compression connections involve using a compression fitting to join the pipe ends. These connections are commonly used in plumbing and gas supply systems and are known for their ease of installation. 6. Grooved connections: Grooved connections involve using grooved couplings to join the pipe ends. These connections are often used in fire protection systems and are known for their quick and simple installation. Overall, the choice of stainless steel pipe end connection depends on the specific application, pressure requirements, ease of installation, and maintenance considerations. It is important to consult with a professional or refer to industry standards to determine the most suitable connection type for your particular needs.

- Q: What is stainless steel pipe made of?

- Stainless steel pipe is primarily made of an alloy consisting of iron, chromium, and other elements such as nickel and manganese. The exact composition of stainless steel pipes may vary depending on the grade or type of stainless steel being used. Generally, stainless steel pipes have a high chromium content (at least 10.5%) which provides excellent corrosion resistance and durability. The addition of other elements helps to enhance various properties of the stainless steel pipe, such as strength, heat resistance, and weldability. Overall, stainless steel pipes are made of a strong and versatile material that is resistant to corrosion, making them suitable for a wide range of applications in industries such as construction, automotive, and manufacturing.

- Q: Are stainless steel pipes resistant to chemical corrosion?

- Yes, stainless steel pipes are resistant to chemical corrosion. This is due to the high levels of chromium present in stainless steel, which forms a protective oxide layer on the surface of the pipes. This oxide layer acts as a barrier, preventing chemical substances from coming into contact with the underlying steel and causing corrosion. Additionally, stainless steel pipes are also resistant to other types of corrosion, such as rusting, making them a popular choice for various industrial, commercial, and residential applications where exposure to chemical substances is expected.

- Q: What are the different types of stainless steel pipe valves?

- Various stainless steel pipe valves are available, each serving specific purposes and industries. Some commonly utilized types include: 1. Ball valves: These valves control fluid flow with a rotating ball featuring a central hole. They possess excellent sealing capabilities, making them suitable for high-pressure applications. 2. Gate valves: Flow control is achieved through a sliding gate in gate valves. They are commonly employed in situations that require a straight-line flow with minimal pressure drop. 3. Globe valves: Globe valves consist of a spherical body and a regulating disc that moves vertically. They offer effective throttling abilities and are often utilized in applications that demand precise fluid flow control. 4. Check valves: These valves permit fluid to flow in only one direction and prevent backflow. They are frequently installed in piping systems to prevent damage caused by reverse flow. 5. Butterfly valves: Butterfly valves utilize a rotating disc within the pipe to regulate flow. Their lightweight, compact nature and cost-effectiveness make them suitable for a wide array of applications. 6. Needle valves: Needle valves possess a slender, tapered stem that allows for precise control over flow rates. They are commonly found in applications that necessitate accurate flow regulation, such as laboratory or instrumentation systems. 7. Pressure relief valves: These valves automatically release excess pressure from a system when it surpasses a certain threshold. They are crucial for maintaining the safety and integrity of piping systems. These examples represent only a fraction of the stainless steel pipe valves available. The choice of valve depends on factors such as fluid type, pressure, temperature, and specific application requirements. It is important to consult with a valve expert or engineer to select the most suitable valve for your specific needs.

- Q: What are the common sizes of stainless steel pipes?

- The common sizes of stainless steel pipes vary depending on their application and industry standards. However, some commonly used sizes include 1/2 inch, 3/4 inch, 1 inch, 1.5 inches, 2 inches, and 4 inches in diameter.

Send your message to us

cold rolled stainless steel welded pipe

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords