Cold Rolled/Hot Dipped Galvanized Steel Coil Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

ASTM,GB,JIS

Technique:

Cold Rolled

Shape:

Round

Surface Treatment:

Galvanized,Color Coated,Oiled,Dry

Steel Grade:

Q195,Q215,Q235

Certification:

ISO,SGS,BV,CE

Thickness:

1.8mm-16mm

Width:

1000mm-1600mm

Length:

according to weight

Outer Diameter:

according to weight

Net Weight:

23mt

Packaging:

Standard Export Packing

Thickness: 0.15-4mm

Width:32-1250mm

Le ID: 508/610mm

Coil Weight: 2-6 tons per coil

Technique: cold-rolled, hot rolled

Zinc Coating: 40-275g/m2

Applications:constractions, building,furniture industry and electrical industry etc.

Production Description:

| Products Name | hot dip galvanized steel coil/Galvanized steel strip |

| Size | Width:32--1250MM |

| Thickness:0.15-4.0mm | |

| Zinc coat | 40-200g/m2(as required) |

| Quality Standard | SGCC SGCD SECC SECD DX51D+Z DX52D+Z |

| Spangle | Zero spangle,regular spangle,normal spangle,big spangle |

| Surface Treatment | chromated and oiled, chromated and non-oiled |

| Application | conatruction,Electrical appliance,furniture,carrying trade,others |

| Workflow | Coil loading→Decoiling→ Pre-straightening→ Buffering→ Fine straightening & feeding→ transverse cutting→ stacking→ cut sheets out |

| package | seaworthy packing, 4 eyes bands and 4 circumferential bands in steel, galvanized metal fluted rings on inner and out edge.Other as customer requirement. |

| Production Capacity | 30000 Tons per Month |

| Loading | Per container can be loaded 25 tons to 27 tons. |

| Port of shipment | Tianjin port |

| Payment | TT or 100% Irrevocable LC at sight |

| Delievery time | 15--20days after receiving your deposit or L/C. |

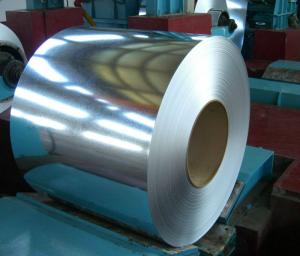

Products Picture

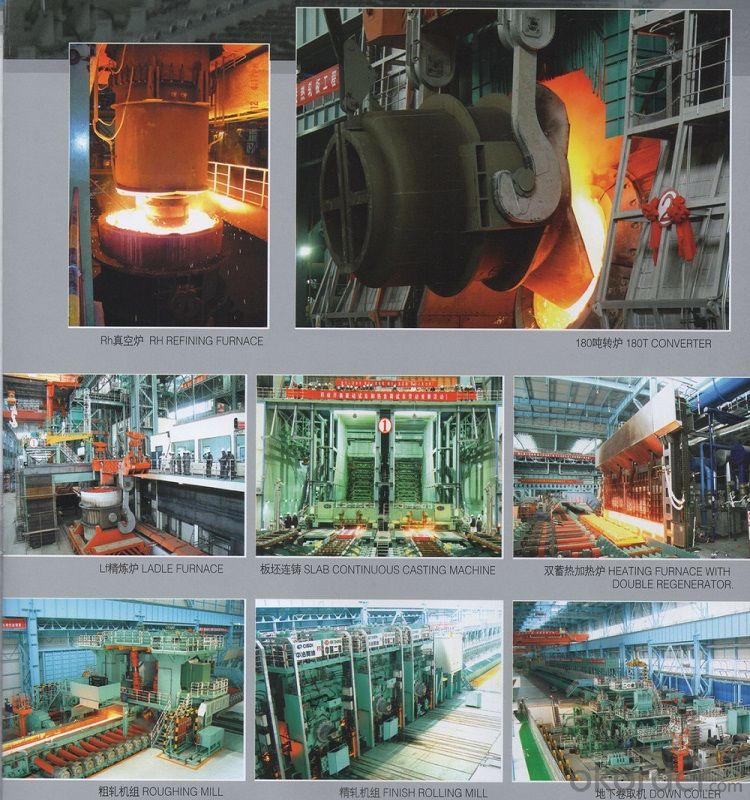

Production porcess

- Q: Can steel coils be coated with silicon?

- Yes, steel coils can be coated with silicon.

- Q: what does steel have inside of it that makes it rust.I need the answer fast!!!!!!!!!

- Steel is made adding carbon to iron.The iron in steel reacts with oxygen in the air, producing ferric oxide(Rust).

- Q: How are steel coils used in the manufacturing of HVAC ductwork?

- Steel coils are used in the manufacturing of HVAC ductwork to form the main structure of the ducts. The steel coils are processed and shaped into specific sizes and dimensions, allowing them to be easily fabricated into duct sections. These coils provide strength and durability to the ductwork, ensuring it can withstand the high pressures and temperatures involved in HVAC systems.

- Q: my step father bought a big steel drum grill it has steel sheets (very thin) that go inbetween the flame and the food (closer to the flame) with that there the food will not cook, it does not get hot enough????? please help... what should we do

- This type of grill cooks like an oven You have to keep the lid shut until the proper temp. is reached. Then place you meats and stuff on the grill and close the lid. Open the lid infrequently to keep the heat in. If its charcoal make sure you use enough charcoal the first time so you don't have to add any while you food is cooking.

- Q: How are steel coils used in the production of metal cabinets?

- Steel coils are a vital element when producing metal cabinets, as they consist of thin steel sheets tightly wound into coils. To begin using steel coils for metal cabinet production, the first step is to uncoil them. This involves unwinding the coil and feeding the steel sheet into a machine that cuts it to the desired length, depending on the size and dimensions of the metal cabinet being manufactured. Once the steel sheet has been cut, it undergoes a process known as blanking. This entails cutting out the necessary panels and parts for the metal cabinet, including the sides, top, bottom, and doors. The blanking process is typically carried out using a stamping press or laser cutting machine to ensure precise shaping of the steel sheet. Following the blanking process, the individual panels are then formed and shaped using a series of bending and forming machines. These machines apply pressure and force to the steel panels, bending them into the desired shape and creating the necessary angles and curves required for the metal cabinet design. After the panels have been formed, they are typically joined together using welding or fastening techniques. Welding involves using heat to fuse the edges of the steel panels together, while fastening techniques may involve the use of screws, bolts, or rivets to securely hold the panels in place. In summary, steel coils are essential in the production of metal cabinets as they provide the raw material for creating the individual panels. The use of steel coils allows for greater flexibility and efficiency in manufacturing metal cabinets, enabling mass production and customization of cabinet designs.

- Q: How are steel coils used in the manufacturing of garage doors?

- Steel coils are used in the manufacturing of garage doors as they are formed and shaped into panels, which provide strength and durability to the doors. The coils are cut and rolled into specific dimensions, then coated with protective layers to enhance corrosion resistance. These panels are then assembled to create the sections of the garage door, ensuring a sturdy and long-lasting product.

- Q: How are steel coils used in the production of rail tracks?

- Steel coils are used in the production of rail tracks as they are processed and shaped into rails. These coils are transformed into long, straight sections of steel that form the main structure of the track. This process involves cutting, bending, and welding the coils to create the desired rail shape and dimensions. The resulting rails are then installed on rail beds to provide a durable and reliable foundation for trains to run on.

- Q: How are steel coils protected from humidity?

- Steel coils are typically protected from humidity through a process called galvanization, where a layer of zinc or another protective coating is applied to the surface of the steel. This coating acts as a barrier, preventing moisture from coming into direct contact with the steel and minimizing the risk of corrosion. Additionally, steel coils are often stored in dry, enclosed spaces or wrapped with moisture-resistant materials such as plastic or wax paper to further protect them from humidity.

- Q: in broken steel can you to missions and get things like the dog, you previously didnt do/get in fallout 3?

- Yes, with Broken Steel there is no end to the game. You survive the main quest where you would die in the original game and may go on to explore the wasteland forever.

- Q: How are steel coils used in the manufacturing of automotive suspension systems?

- Steel coils are used in the manufacturing of automotive suspension systems as they provide the necessary support and stability to withstand the weight and movement of the vehicle. These coils are typically shaped into springs and installed in the suspension system to absorb shocks, maintain proper ride height, and improve overall handling and comfort for the driver and passengers.

Send your message to us

Cold Rolled/Hot Dipped Galvanized Steel Coil Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords