Cold Rolle Steel Coil DC01 DC01EK DC04EK

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Details of Cold Rolle Steel Coil

The raw material of cold rolled steel coil is high quality hot rolled product, and after pickling, continuous rolling, degreasing, annealing, skin pass, slitting and cut to length line etc.

Along with it many kinds of new technology and new process of global cold rolling production have been applied. Therefore the quality of the goods could be guaranteed.

Standard: AISI,ASTM,BS,DIN,GB,JIS

Grade: DC01

Thickness:0 .8/1.0/1.2/1.5

Technique: Cold Rolled

Surface Treatment: Bright or black annealed

Width: 900mm-1500mm

Steel Grade: DC01, DC01EK, DC04EK

Tensile Strength: 270Mpa

Yield Strength: 270-410Mpa

AVAILABLE SPECIFICATION

| Thickness | 0.3-4.0mm (Full Hard Starting From 0.10mm) |

|---|---|

| Width | 30-2000mm |

| Sheets Length | 0-6000mm |

| Coil ID | 508mm or 610mm |

| Surface Treatment | Matt Finish/Bright Finish, Oil/Dry |

| Annealing Methods | Bright Anneal/ Black Anneal |

| Coil Weight | 5MT-25MT |

| APPLICATION | Steel Drum,Galvanized Steel, Steel Pipe, Home Appliance,Automobile etc. |

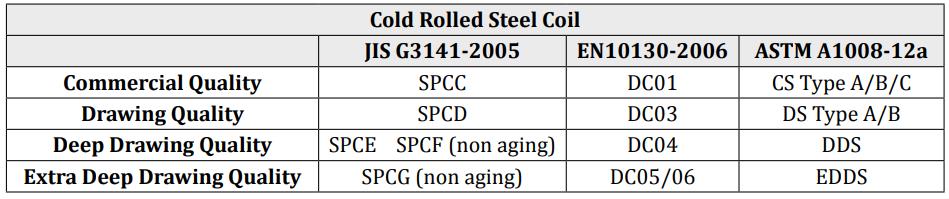

STANDARD & GRADE

Package & Shipment

| Package | Export standard packing(can do as required) |

| Container shipment | 20ft container/40ft container |

| Bulk shipment | if big order,then will save freight cost(while shipline may only one time one month) |

| Delivery | 20days(short as 7days,as many sizes in stock ) |

Picture of Cold Rolle Steel Coil

APPLICATION

Steel Drum, Galvanized Steel, Steel Pipe, Home Appliance, Automobile etc.

- Q: Measures to prevent cold rolling of packaged cold rolled steel coils? Who can give some professional opinions oh?

- Cold rolled steel coils are generally sprayed antirust oil, according to user requirements, light, medium, heavy oil 3 types. Nevertheless, if the oil is volatile or in a humid environment, the steel plate comes into contact with the water for a period of time, indicating that it is beginning to rust.

- Q: I bought this Brinks pad lock and it says boron steel on the lock. I was just wondering what exactly is boron steel and how hard/tough is it?

- Boron steel is rather hard, it is by no means titanium, but certainly better than mild steel. However, as with all metals, hardness is inversely proportional to flexibility, meaning that a good solid whack with a sledge hammer could crack your lock.

- Q: What are the challenges in coil slitting for narrow strip widths?

- Coil slitting for narrow strip widths presents a number of challenges. One key challenge is the need to maintain precision and accuracy throughout the slitting process. Even the smallest misalignment or deviation can result in significant defects or inconsistencies in the final product. Therefore, it is important to calibrate and adjust the slitting equipment carefully to ensure accurate cuts. Another challenge is the risk of material damage or deformation during slitting. Narrow strip widths are more susceptible to distortion, wrinkling, or edge cracking, especially if the material is not handled or supported properly. To minimize potential damage, it is necessary to feed the material smoothly through the slitting machine and control the tension effectively. In addition, handling and transporting slit coils can be challenging due to their narrow width. These coils are prone to bending, twisting, or telescoping, which can cause difficulties in stacking, storage, or transportation. To maintain the shape and integrity of the coils, proper packaging and handling techniques must be employed throughout the supply chain. Furthermore, narrow strip widths often require more frequent blade changes during slitting. This adds complexity and time to the setup and maintenance process, as the blades need to be carefully selected and replaced for optimal cutting results. Skilled technicians are crucial for efficiently and effectively handling these blade changes. Overall, while coil slitting for narrow strip widths offers cost savings and increased material utilization, it also comes with challenges that need to be addressed. These challenges include maintaining accuracy, preventing material damage, ensuring proper handling and transportation, and managing blade changes effectively. By understanding and addressing these challenges, manufacturers can optimize their coil slitting operations and produce high-quality narrow strip products.

- Q: How are steel coils used in the manufacturing of building materials?

- Steel coils are widely used in the manufacturing of building materials due to their strength, durability, and versatility. These coils are typically made from high-quality steel and are shaped into a continuous, flat strip. One of the most common uses of steel coils in building materials is for the production of steel roofing and siding. The coils are processed through a series of machines that cut, shape, and roll the steel into the desired dimensions and profiles. The resulting roofing and siding materials are then used to construct durable and weather-resistant building envelopes. Steel coils are also used in the manufacturing of steel studs, which are essential components for framing structures. The coils are cut and formed into precise shapes, then assembled to create a strong and rigid framework for walls, ceilings, and other structural elements. Steel studs offer numerous advantages such as high strength-to-weight ratio, fire resistance, and dimensional stability, making them a popular choice in the construction industry. In addition to roofing, siding, and framing, steel coils are utilized in the production of various other building materials. These include steel pipes, beams, columns, and reinforcement bars, which are used in the construction of foundations, infrastructure, and structural elements. Steel coils also serve as raw materials for the fabrication of metal panels, doors, windows, and other architectural components. Overall, steel coils play a crucial role in the manufacturing of building materials as they provide the necessary strength and durability required for long-lasting and robust structures. Their versatility allows for the production of a wide range of building components, making steel coils an indispensable resource in the construction industry.

- Q: What is the weight range of steel coils?

- The weight range of steel coils can vary greatly depending on the specific type and dimensions of the coil. However, typically, steel coils can weigh anywhere from a few hundred kilograms to several tonnes.

- Q: I'm pretty sure that this topic has been beaten to death by now. But, I still can't get a definite answer. With stainless steel, you get better corrosion resistance, and you will hold and edge longer. With carbon steel, you will hold a sharper edge, and you could forge a knife blade longer than 2 ft without breakage. I'm personally a fan of stainless steel ( the 440 grade stuff ), just because it seems to hold up to use and abuse better in the long run. HOWEVER, I have NEVER had a factory made knife break on me. I don't think that they would try to sell you a knife that didn't do what it was meant to do, at least to a reasonable degree. (I work for a living, and can't afford a custom $600 knife.) What do you think? Is this a pointless topic? Will there ever be a winner?

- I hate stainless steel! I hate shiny blades also! When I was a kid knifes were awesome! You could actually sharpen them! :) If we bought a new knife we would take an orange and slice it and leave the juice on the blade to purposefully darken it. If you had a shiny blade that looked like stainless you were not cool. :) I think most anyone who had an old knife from back in the 70's or before would agree that these new stainless knives are crap. I have not seen anything perform close to the old blades in stainless. Today I bought a case CV Sod Buster hoping it will perform like the old knives. What reading I have done the Chrome Vanadium is supposed to be like the old steel. I sure hope it is. Now to find some fruit to get rid of this annoying shiny blade! :)

- Q: I was wondering if anyone knew the grade/type of steel for this product. I'd like to use it as stock for a knife blade, but would like to know the specs so I can determine if it is suitable and, if so, how best to heat treat it.Thanks.PS: I know it isn't stainless, but that leaves a lot of other steel types.

- Flat Steel Bar

- Q: I have to explain some functions of stainless steel but after days of searching I cant find an answer. Thankyou in advance for your help :)

- nicely worth little or no so a great way as i'm in contact. It has an somewhat destructive co useful of heat, is confusing to lubricate to maintain the meals from sticking and could strengthen a warm spot somewhat. My decision is a good high quality forged iron, it extremely is heavy yet conducts warmth nicely and spreads it flippantly. Stainless with copper bottoms is marginal for boiling water whether it does sparkling somewhat. There are countless alloys on the industry that are usable as cook dinner ware. Aluminum is worse than stainless. Of the organic metals, copper is the suited conductor of heat, forged iron is my decision, spun metallic does artwork. desire this helps. never wash forged iron cookware with cleansing soap and water.

- Q: What are the safety considerations when handling steel coils?

- When handling steel coils, it is important to consider safety measures to prevent accidents or injuries. Some key safety considerations include: 1. Proper training: All personnel involved in handling steel coils should receive adequate training to understand the risks associated with the task and learn proper handling techniques. 2. Personal protective equipment (PPE): Workers should wear appropriate PPE such as gloves, safety boots, and eye protection to protect against cuts, punctures, or other injuries. 3. Load capacity and stability: Ensuring that lifting equipment and machinery used for handling steel coils have the necessary load capacity and stability is crucial to prevent accidents or equipment failures. 4. Proper lifting techniques: Using correct lifting techniques, such as bending the knees and lifting with the legs rather than the back, helps to minimize the risk of strains or back injuries. 5. Secure storage: Steel coils should be stored in a secure and organized manner, with proper blocking, bracing, or racking systems in place to prevent them from shifting or falling. 6. Inspection and maintenance: Regular inspection of lifting equipment, hooks, slings, and other accessories is essential to identify any signs of wear or damage that could compromise safety. 7. Communication and coordination: Establishing clear communication protocols and coordination among workers involved in handling steel coils can help prevent accidents, especially in areas with limited visibility or restricted access. 8. Hazard identification and mitigation: Identifying potential hazards such as sharp edges, loose straps, or uneven surfaces, and taking appropriate measures to mitigate these risks, is vital to ensure safe handling practices. By considering these safety measures, the risk of accidents or injuries associated with handling steel coils can be significantly reduced.

- Q: What is the average lead time for receiving replacement steel coils?

- The average lead time for receiving replacement steel coils can vary depending on various factors such as supplier availability, shipping logistics, and order requirements. However, it is common for lead times to range from a few days to several weeks. It is advisable to contact the specific supplier or manufacturer for accurate and up-to-date information on lead times.

Send your message to us

Cold Rolle Steel Coil DC01 DC01EK DC04EK

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords