Cold Drawn Carbon Steel Flat Bar S45C & 4140 & 5140 & 20CrMnTi & S20C

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 45000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of Cold Drawn Carbon Steel Flat Bar S45C & 4140 & 5140 & 20CrMnTi & S20C:

OKorder is offering high quality Slit Cutting Flat Bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Applications of Cold Drawn Carbon Steel Flat Bar S45C & 4140 & 5140 & 20CrMnTi & S20C:

Slit Cutting Flat Bars are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Advantages of Cold Drawn Carbon Steel Flat Bar S45C & 4140 & 5140 & 20CrMnTi & S20C:

OKorder's Slit Cutting Flats Barare durable, strong, and resist corrosion.

Main Product Features of Cold Drawn Carbon Steel Flat Bar S45C & 4140 & 5140 & 20CrMnTi & S20C:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications of Cold Drawn Carbon Steel Flat Bar S45C & 4140 & 5140 & 20CrMnTi & S20C:

Manufacture: Slit Cutting

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

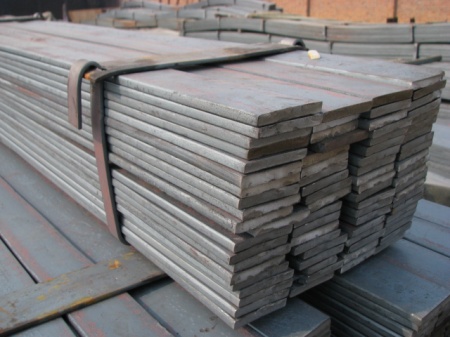

Images of Cold Drawn Carbon Steel Flat Bar S45C & 4140 & 5140 & 20CrMnTi & S20C

I

- Q: The distinction between flat steel and steel strip

- Blue is to heat the steel or directly immersed in concentrated oxidizing solution in the air, material protection technology of oxide film on the surface of thin produce, also known as black. The blue steel parts can be carried out in the molten salt of sodium nitrite and sodium nitrate, can also be carried out at high temperature above 500 DEG C hot air and superheated steam, the more common is heating sodium nitrite in concentrated caustic soda. Solution composition, reaction time and the temperature of Bluing depends on steel matrix composition. Bluing film composition is magnetic iron oxide, the thickness of 0.5 to 1.5 microns, the color and the material composition and process conditions, a dark gray, dark blue, etc.. Bluing film separate corrosion resistance is poor, but the oil wax or paint varnish, corrosion resistance and friction resistance are improved. Blue, the workpiece has little effect on the quality of size and finish. It is commonly used in precision instruments, optical instruments, tools, hardness blocks and so on.

- Q: What are the different cleaning and maintenance methods for steel flat bars?

- There are several cleaning and maintenance methods for steel flat bars that can help keep them looking and performing their best. Some of the most common methods include: 1. Regular Cleaning: The first step in maintaining steel flat bars is regular cleaning. This can be done using a mild detergent or soap and water solution. Simply apply the solution to the surface of the flat bar and use a soft cloth or sponge to gently scrub away any dirt or grime. Rinse the bar thoroughly with clean water and dry it using a soft, lint-free cloth. 2. Polishing: Polishing the steel flat bars can help restore their shine and remove any surface scratches or marks. There are various metal polishes available in the market specifically designed for stainless steel surfaces. Apply a small amount of polish to a microfiber cloth and rub it onto the surface of the flat bar in circular motions. Continue polishing until the desired shine is achieved. 3. Stainless Steel Cleaner: For tougher stains or marks that regular cleaning cannot remove, a stainless steel cleaner can be used. These cleaners are designed to break down and remove stubborn stains, grease, and grime from stainless steel surfaces. Follow the instructions on the cleaner's packaging for best results. 4. Rust Prevention: Steel flat bars are susceptible to rust, especially in humid or corrosive environments. To prevent rust, it is important to keep the flat bars dry and avoid prolonged exposure to moisture. If any rust spots do appear, they should be promptly removed using a rust remover or a mixture of vinegar and baking soda. After removing the rust, clean and dry the flat bar thoroughly to prevent further rusting. 5. Protective Coatings: Applying a protective coating or sealant to steel flat bars can help enhance their resistance to staining, corrosion, and scratches. There are various products available such as clear lacquers, paints, or specialized coatings specifically designed for stainless steel surfaces. Follow the manufacturer's instructions for proper application and maintenance of the protective coating. By following these cleaning and maintenance methods, steel flat bars can maintain their appearance and durability for a longer period of time, ensuring optimal performance in various applications.

- Q: Can steel flat bars be used for making hand tools?

- Yes, steel flat bars can be used for making hand tools. Steel is a strong and durable material, making it suitable for crafting various hand tools such as wrenches, screwdrivers, chisels, and more. The flat shape of the bar can easily be shaped and manipulated into the desired tool design.

- Q: How do steel flat bars perform in terms of thermal expansion?

- Steel flat bars have a relatively low coefficient of thermal expansion, meaning they expand and contract less compared to other materials when exposed to temperature changes. This makes them highly stable and resistant to warping or distortion due to thermal effects.

- Q: What is the representation of flat steel?

- In use, it has advantages over steel platesFlat steel adopts negative deviation rolling, but according to actual weight, the utilization ratio of steel plate is 1~5 percentage points higher than that of steel plate.Flat can according to user needs, set the thickness, width and length of production, for the user to reduce the cut and save processes, reducing labor, material consumption, but also reduce the loss of raw materials processing, time saving, material saving. Products have been specialized in steel structure manufacturing, machinery manufacturing, automotive industry, mining machinery, lifting machinery and other industrial materials.

- Q: Hot dip galvanized flat steel specification 40X4, 60X6 meaning?

- Hot galvanizing is a kind of anticorrosive process. It is coated with zinc on the surface of the plated parts. Zinc is relatively stable in the air. 40x4 60x6 is the width and thickness of the plated part, in mm

- Q: What are the applications of steel flat bars?

- Steel flat bars have a wide range of applications across various industries. One of the most common uses is in construction and structural engineering. Steel flat bars are often used as a structural component in buildings, bridges, and other infrastructure projects. They provide strength and stability to these structures and can withstand heavy loads and forces. In the manufacturing industry, steel flat bars are utilized in the production of machinery and equipment. They are commonly used as a base or support for heavy machinery, as well as in the construction of frames, brackets, and components. The high strength and durability of steel flat bars make them ideal for these applications, as they can withstand the stress and pressure generated during operation. Steel flat bars also have applications in the automotive industry. They are often used in the manufacturing of vehicle frames, chassis, and body panels. The strength and rigidity of steel flat bars ensure the structural integrity of automobiles, providing safety and stability to the vehicle. Moreover, steel flat bars find applications in the fabrication industry. They are commonly used in the production of gates, fences, grills, and handrails. The versatility of steel flat bars allows them to be easily shaped, cut, and welded, making them an ideal choice for custom fabrication projects. In addition to these industries, steel flat bars have various other applications. They are commonly used in the manufacturing of furniture, shelves, and storage racks due to their high load-bearing capacity. Steel flat bars are also utilized in the production of agricultural equipment, such as plows and harrows, as well as in the manufacturing of tools and hardware. Overall, the applications of steel flat bars are vast and diverse. Their strength, durability, and versatility make them a popular choice in construction, manufacturing, automotive, fabrication, and many other industries.

- Q: Can steel flat bars be used for agricultural applications?

- Yes, steel flat bars can be used for agricultural applications. Steel is known for its strength and durability, making it suitable for various agricultural tasks. Steel flat bars can be used for constructing fences, gates, and livestock enclosures, providing a sturdy and long-lasting solution. They can also be used as support beams or braces for structures like barns or sheds. Additionally, steel flat bars can be used for creating custom implements or machinery parts, such as plow blades or cultivator tines. Overall, steel flat bars offer the necessary strength and versatility required for agricultural applications.

- Q: Can steel flat bars be easily painted or coated?

- Steel flat bars can be painted or coated with ease. The sleek and even surface of steel flat bars allows for a simple application of paint or coatings. Before painting or coating, it is crucial to ensure that the surface is clean and devoid of any rust, dirt, or grease. This can be achieved by sanding the surface and using a suitable cleaner or solvent. Once the surface is properly prepared, a primer can be applied to enhance the adhesion and durability of the paint or coating. Finally, the desired paint or coating can be applied using a brush, roller, or spray method. It is advisable to follow the manufacturer's instructions for the specific paint or coating being used. In general, steel flat bars offer a suitable surface for painting or coating and can be easily transformed to meet various aesthetic or protective requirements.

- Q: Can steel flat bars be painted or coated?

- Yes, steel flat bars can be painted or coated.

Send your message to us

Cold Drawn Carbon Steel Flat Bar S45C & 4140 & 5140 & 20CrMnTi & S20C

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 45000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords