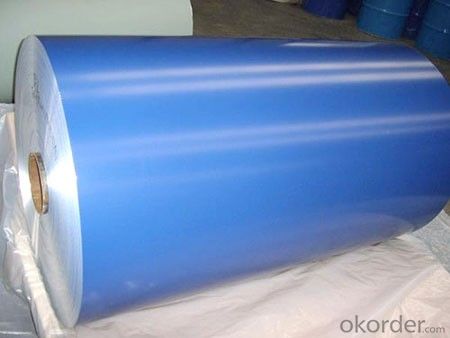

Coated Aluminum Pipes Coil-AA1100

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.General Information of Color Coated Aluminium Coil with Competitive Prices

Aluminum coil is between 0.1 mm and 500mm in thickness and has a wide variety of uses in the construction industry including aluminium siding and roofing. Sheet is also used widely in construction, decoration, transport applications and other various industrial filed, such as automobile body panels, airframes, curtain walls and the hulls of boats etc.

Alloy | AA1050,AA1060, AA1070, AA1100, AA3003, AA3004, AA3005, AA3105, AA5005, AA5052, AA5754, AA5083, AA8011 |

Temper: | H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness: | 0.10-4.0mm |

Width: | 10mm- 2000mm |

Coating | PE(Polyester) |

Painting Thickness | Standard 16-25 microns, max 40 microns |

Color | Acording to Ral colors or customer’s samples |

Standard: | GB/T17748-1999, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement | |

PE(polyester) Coating

PE(polyester) coating:high molecular polymer as monomer and addition of alkyd, is an UV-resistant coating. It can be classified matt and glossy according to coating gloss. The compact molecule structure, makes paint surface luster and smooth,which assure good printing on the panel surface. With an warranty of 8-10 years for weather resistance, it is specially applied for internal decoration and sign board.

2 Usage/Applications of PE Coated Aluminum Coil/Sheet

Our company's PE Coated Aluminum Coil/Sheet have been widely used in the fields of construction and decoration(garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipe, sanwich panels and drainage, etc.

- Q: 6063, how to prevent cracking aluminum tube, variant manual bending machine bending machine bending, what should pay attention to?No one knows?

- 6063, aluminum tube plasticity is very good, if you want to bend, it is recommended to return the fire, reduce the hardness, bending after quenching, bend pipe bend can be.

- Q: How to weld air conditioning round aluminum tube

- Welding air conditioning thin aluminum tube is mainly a few aspects1, thin aluminum pipe appear grinding leakage, appear big hole2, use for a long time, the needle hole fatigue3, because of corrosion caused by the hole

- Q: Can aluminum pipes be used for cooling tower installations?

- Yes, aluminum pipes can be used for cooling tower installations. Aluminum is a lightweight and corrosion-resistant material, making it suitable for cooling applications. It is commonly used in the construction of heat exchangers and cooling systems due to its high thermal conductivity and durability. Additionally, aluminum pipes have excellent heat transfer properties, allowing for efficient heat dissipation and effective cooling. However, it is important to consider the specific requirements of the cooling tower system, such as temperature, pressure, and water chemistry, to ensure that aluminum pipes are compatible and can withstand the operating conditions.

- Q: Are aluminum pipes suitable for pulp and paper processing?

- Yes, aluminum pipes are suitable for pulp and paper processing. Aluminum is a versatile and durable material that offers several advantages for this particular application. Firstly, aluminum pipes are lightweight, making them easier to handle and install compared to other materials. This can help reduce labor and transportation costs during the construction or maintenance of pulp and paper processing facilities. Additionally, aluminum pipes have excellent corrosion resistance properties. In the pulp and paper industry, there are various corrosive substances and chemicals involved in the processing of pulp and the production of paper. Aluminum's inherent resistance to corrosion makes it a suitable choice for transporting these substances without the risk of pipe degradation or contamination. Furthermore, aluminum pipes offer high heat conductivity, which can be beneficial in certain stages of pulp and paper processing that involve temperature control. This heat conductivity allows for efficient heat transfer, resulting in improved energy efficiency and cost savings. Moreover, aluminum is a recyclable material, aligning with the industry's increasing focus on sustainability and environmental responsibility. Recycling aluminum pipes can help reduce greenhouse gas emissions and conserve natural resources. However, it is important to consider the specific requirements of each application within the pulp and paper processing industry before making a final decision on material selection. Some processes or environments may call for different materials based on factors such as pressure, temperature, or chemical compatibility. Consulting with industry experts or engineers can help determine the best material choice for a specific application.

- Q: Water heater tube welding seam how

- Two, low temperature 400 degrees aluminum welding method, with third generations of WE53 liquefied gas porous spray gun as heating source of heat, and then with WEWELDING Q303 welding wire spot welding, has good permeability.

- Q: What are the benefits of an aluminum tube cigar?

- The best start glass tube, sealed to preserve the original flavor

- Q: Can aluminum pipes be anodized for improved corrosion resistance?

- Yes, aluminum pipes can be anodized to enhance their corrosion resistance. Anodizing forms a protective oxide layer on the surface of the aluminum, increasing its resistance to corrosion and improving its durability.

- Q: The aluminum extrusion seam? Is there a big difference between the two?

- Seamless aluminum tube production process: reverse through the core (hole) to form seamless pipeThe production process of aluminum tube seam: conventional tubes is generally used for combination die extrusion, which is produced by extrusion, is welded, the welding seam is automatically in high temperature.

- Q: Aluminium tube production and equipment. What are the production techniques and what equipment are needed? How much will it cost?.

- Responsible for the design, development, tooling development and production of new product tubes (thin-walled tubes, rectangular tubes, tubes), as the new product development manager.

- Q: How can I bend an aluminum tube into an oval shape?What is the best solution?What is the most economical solution?ThanksIn the ordinary bending machine, it is feasible to change the arc in order to change the radius from the radius to the short axis firstSo, the whole pipe can only be bent into ellipses with more clamps?

- Pull the solid die upwards! You can also do more bending! This needs professional! I'm a professional elbow! It can also be bent in sections!

Send your message to us

Coated Aluminum Pipes Coil-AA1100

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches