Coated Aluminum Pipes Coil-AA3105

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

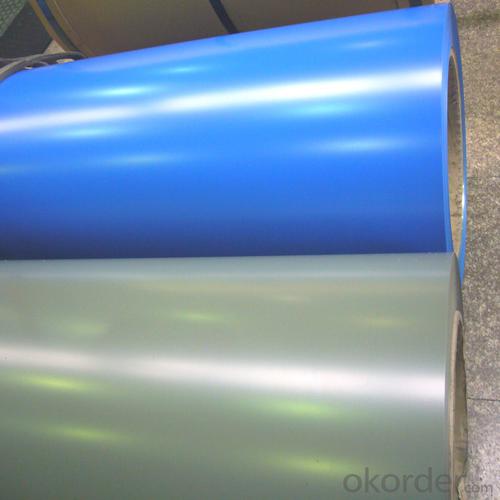

1.General Information of Color Coated Aluminium Coil with Competitive Prices

Aluminum coil is between 0.1 mm and 500mm in thickness and has a wide variety of uses in the construction industry including aluminium siding and roofing. Sheet is also used widely in construction, decoration, transport applications and other various industrial filed, such as automobile body panels, airframes, curtain walls and the hulls of boats etc.

Alloy | AA1050,AA1060, AA1070, AA1100, AA3003, AA3004, AA3005, AA3105, AA5005, AA5052, AA5754, AA5083, AA8011 |

Temper: | H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness: | 0.10-4.0mm |

Width: | 10mm- 2000mm |

Coating | PE(Polyester) |

Painting Thickness | Standard 16-25 microns, max 40 microns |

Color | Acording to Ral colors or customer’s samples |

Standard: | GB/T17748-1999, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement | |

PE(polyester) Coating

PE(polyester) coating:high molecular polymer as monomer and addition of alkyd, is an UV-resistant coating. It can be classified matt and glossy according to coating gloss. The compact molecule structure, makes paint surface luster and smooth,which assure good printing on the panel surface. With an warranty of 8-10 years for weather resistance, it is specially applied for internal decoration and sign board.

2 Usage/Applications of PE Coated Aluminum Coil/Sheet

Our company's PE Coated Aluminum Coil/Sheet have been widely used in the fields of construction and decoration(garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipe, sanwich panels and drainage, etc.

- Q: Please enlighten master formula of tube weight?

- Aluminium tube weight (kg) =0.00879 * wall thickness * (outside diameter wall thickness) * length (M), remaining mm

- Q: Are aluminum pipes suitable for architectural applications?

- Aluminum pipes are indeed appropriate for architectural purposes. They possess the qualities of being lightweight and versatile, which provide numerous advantages for architectural applications. To begin with, aluminum pipes exhibit resistance to corrosion, making them an ideal choice for outdoor structures that face harsh weather conditions. This durability ensures that the pipes will have a longer lifespan and require less maintenance in comparison to alternative materials. Furthermore, aluminum pipes can be easily fabricated and molded into various shapes and sizes, thereby allowing for greater design flexibility. This makes them suitable for a wide array of architectural applications, including handrails, curtain walls, window frames, and structural supports. The capability to customize and shape aluminum pipes also empowers architects to create distinctive and visually appealing designs. Moreover, aluminum is an environmentally friendly material as it is highly recyclable and necessitates less energy for production when compared to other metals. This aligns perfectly with the growing emphasis on sustainable and environmentally conscious building practices prevalent in the architectural industry. To summarize, the lightweight nature, resistance to corrosion, and ease of customization possessed by aluminum pipes render them a suitable option for architectural applications. They provide durability, design flexibility, and environmental benefits, making them the preferred material for modern architectural projects.

- Q: Can aluminum pipes be used for structural supports in buildings?

- Yes, aluminum pipes can be used for structural supports in buildings. Aluminum is a lightweight and durable material that offers excellent corrosion resistance, making it suitable for various construction applications. However, the specific design requirements, loads, and building codes should be considered when determining the suitability of aluminum pipes for structural support in a building.

- Q: Can aluminum pipes be used for compressed air systems?

- Indeed, one can utilize aluminum pipes for compressed air systems. Aluminum pipes present numerous benefits when employed in compressed air applications. Primarily, the lightweight nature of aluminum facilitates handling and installation processes. Moreover, aluminum pipes possess corrosion resistance, an essential characteristic for preserving the integrity of the compressed air system. The smooth interior surface of aluminum pipes further reduces friction and pressure loss, thereby enhancing air flow efficiency. Additionally, aluminum is non-toxic and does not discharge any detrimental substances into the compressed air. In summary, aluminum pipes represent a dependable and economical option for compressed air systems.

- Q: Can aluminum pipes be used for irrigation valves?

- Yes, aluminum pipes can be used for irrigation valves. Aluminum is a durable and lightweight material that is resistant to corrosion, making it suitable for irrigation systems.

- Q: What are the different wall thickness options for aluminum pipes?

- The wall thickness options for aluminum pipes can vary depending on the specific application and industry requirements. Generally, aluminum pipes are available in a range of wall thicknesses to accommodate different needs. The most common options for wall thicknesses in aluminum pipes include standard, schedule, and nominal sizes. Standard wall thicknesses are typically used in industrial applications where strength and durability are important. These pipes are manufactured with specific dimensions to meet industry standards and are often used in structural applications, such as construction or engineering projects. Schedule wall thicknesses, on the other hand, are primarily used in pressure applications, such as plumbing or fluid transfer systems. These pipes are designed to handle different levels of pressure and are identified by a schedule number, ranging from Schedule 5 to Schedule 160. Each schedule number corresponds to a specific wall thickness, with higher numbers indicating thicker walls capable of withstanding higher pressures. Nominal wall thicknesses refer to a range of wall thicknesses that fall within a certain tolerance level. These pipes are often used in general-purpose applications or where precise dimensions are not critical. The nominal size is a rounded value that corresponds to the approximate inside diameter of the pipe, while the wall thickness can vary within a certain range. It is important to note that the specific wall thickness options for aluminum pipes may vary depending on the manufacturer, industry standards, or custom requirements. Therefore, it is essential to consult the relevant specifications or consult with a supplier to determine the available options for a particular application.

- Q: Villa reconstruction, taking into account the importance of water supply and drainage, to choose some good pipe. I looked at the Sorbonne piersa, HSBC, Kim these tubes inside, so some of the pipe plastic pipe and plastic pipe PPR divided into different categories such as pipes, these pipes in the end what is the difference? Which is better?

- According to you, you should see is "aluminum pipe" and "PPR plastic aluminum steady pipe" these two, in fact, in general, there are third common, that is, "RPAP5 butt welding aluminum pipe"Plastic pipe is a pipe is popular, you said piersa Sorbonne, Kim, HSBC are producing the pipe brand manufacturers, is more trustworthy. One should note that piersa pipe fakes more, we must look for the brand is the Sorbonne tube in order to prevent being cheated.

- Q: Can aluminum pipes be used for water treatment filters?

- Yes, aluminum pipes can be used for water treatment filters. Aluminum is a versatile material that is commonly used in various industries, including water treatment. Aluminum pipes are known for their durability, corrosion resistance, and lightweight nature, which make them suitable for use in water treatment filters. They are often used in applications such as filtration systems, where they can effectively remove impurities and contaminants from water. Additionally, aluminum pipes can be easily modified and customized to meet specific requirements, making them a preferred choice for water treatment processes. However, it is important to ensure that the aluminum pipes used for water treatment filters meet the necessary standards and regulations to ensure the safety and quality of the treated water.

- Q: Can aluminum pipes be used for gas transportation?

- Gas transportation can indeed utilize aluminum pipes. Renowned for its lightweight and robust nature, aluminum boasts exceptional corrosion resistance. Consequently, this material finds widespread application across diverse industries, including gas transportation, thanks to its capacity to endure elevated pressure and temperature circumstances. Furthermore, handling and installing aluminum pipes prove more convenient than their steel counterparts. Nonetheless, it remains crucial to ensure adequate coating or lining of the aluminum pipes to avert any potential interaction between the gas and the metal, as certain gases may react unfavorably with aluminum.

- Q: Can aluminum pipes be used for irrigation sprinkler systems?

- Yes, aluminum pipes can be used for irrigation sprinkler systems. Aluminum pipes are lightweight, durable, and resistant to corrosion, which makes them a suitable choice for irrigation systems. They are also easy to install and can withstand high-pressure water flow. Additionally, aluminum pipes have a longer lifespan compared to other materials, such as PVC or galvanized steel, which makes them a cost-effective option for irrigation systems. However, it is important to consider the specific requirements of the irrigation system and consult with a professional to ensure that aluminum pipes are the best choice for your specific needs.

Send your message to us

Coated Aluminum Pipes Coil-AA3105

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches