cnbm color coated aluzinc steel coil for constuction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 300000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | SGCC/DX51D | Thickness: | (0.13~1.2)MM,0.14~0.8mm |

| Place of Origin: | Shandong China (Mainland) | Brand Name: | CNBM | Model Number: | (0.13~1.2)MM*(600~1250)MM |

| Type: | Steel Plate | Technique: | prepainted | Surface Treatment: | Coated |

| Application: | construction material/roofing sheet,construction material | Special Use: | Silicon Steel | Width: | (600~1250)MM,600~1250mm |

| Length: | L,1000~6000mm | Material: | SGCC/DX51D | Color: | Brown |

| zinc coating: | 80g-180g | Products name: | color coated Aluzinc coated steel coil | End use: | construction material |

| Size: | (0.14~0.8)mm*(600~1250)mm |

Packaging & Delivery

| Packaging Detail: | exporting seaworthy package for aluzinc coated steel coils |

| Delivery Detail: | within10~50days |

Specifications

Manufacturer of color coated Aluzinc coated steel coil,PPGL steel coil,GI,GL,Corrugated steel coil,Composite pannel,etc

Name:china manufacturer color coated Aluzinc coated steel coil/ppgl steel coil for construction

Base material: sgcc,dx51d

Thickness:0.14mm-0.8mm.

Width:600mm-1250mm.

Zinc coating:80g-180g

Color: all RAL colors to your demands.

ID and weight: 508mm-610mm. 3-12ton

PRE-PAINTED GALVANIZED STEEL COIL DETAILED SPECIFICATION

1) AVAILABLE DESIGNATION

Quality | Q/BQB 440-2003 | JIS G3312-1994 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

Commercial Steel | TDC51D | CGCC | DX51D+Z/AZ | CS Type A/B/C |

Forming Steel | (TSt01,TSt02,TSt03) | CGCD1 | FS Type A, Type B | |

Drawing steel | TDC52D /TDC53D | - | DX52D+Z/AZ | DDS TYPE A/C |

DX53D+Z/AZ | ||||

Structural Steel | TS280GD(TStE28) | CGC400 | S280D+Z/AZ | SS275 |

TS350GD(TStE34) | CGC440 | S350D+Z/AZ | SS340 Class1 |

2) OUR SPECIFICATION

Available Size:

Manufacturer | Thickness | Width | Length of plate | Inner diameter of coil |

SHANDONG LONGFA STEEL PLATE | 0.18-1.2mm | 800/914/1000/1200/1219/1250mm | 1000-6000mm | 508mm/610mm |

Coated Mass:

Base plate | Available Coated Mass(g/m^2)

|

Galvanized Steel | 60,80, 100, 120, 160, 180 |

Galvalume Steel | 50, 70, 150 |

Available Painting:

Category of Painting | Item | Code | |

Polyester | PE | ||

High-durability polyester | HDP | ||

Silicon modified polyesters | SMP | ||

Polyvinylidene fluoride | PVDF | ||

Easy-Cleaning | — | ||

Painting Thickness | Top side: 20±5microns; | ||

Bottom side: 5~7microns. | |||

Color System | Produce according to RAL Color System or as per buyer’s color sample. | ||

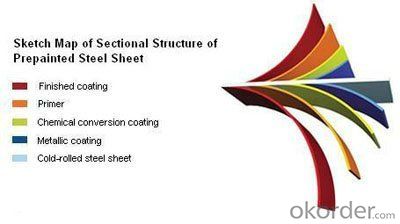

Painting structure | Top surface | Bottom surface | |

Primer coating | No coating | 1/0 | |

Primer coating | Primer coating | 1/1 | |

Primer coating + Finish coatin | No coating | 2/0 | |

Primer coating + Finish coating | Primer coating or single back coating | 2/1 | |

Primer coating + Finish coating | Primer coating + Finish back coating | 2/2 | |

Note: Protect film available

3) APPLICATION OF OUR PREPAINTED STEEL

Construction | Outside | Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth |

Inside | Door, doorcase, light steel roof structure, folding screen, elevator, stairway, vent gutter | |

Electrical appliance | Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker | |

Furniture | Central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf | |

Carrying trade | Exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board | |

Others | Writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment | |

4)ISO CERTIFICATE

5)PPGI PRODUCE PROCESS

- Q: What are the different types of steel coil surface coatings?

- Steel coils can be enhanced in terms of durability, corrosion resistance, and aesthetic appearance through the use of various types of surface coatings. The most commonly employed coatings are as follows: 1. Zinc Coatings: These are widely utilized to safeguard steel against corrosion. A layer of zinc is applied to galvanized steel coils, acting as a barrier against moisture and other environmental elements. 2. Galvannealed Coatings: This type of coating combines zinc and iron, providing improved corrosion resistance and enhancing paint adhesion. It is ideal for applications that require painting. 3. Aluminum Coatings: Aluminum coatings are employed to achieve a lightweight and corrosion-resistant surface. Steel coils coated with aluminum are frequently utilized in the automotive industry for body panels and other parts that require high strength and corrosion resistance. 4. Organic Coatings: Organic coatings, typically in the form of paint or powder coatings, offer protection against corrosion. They also provide a wide range of color options for aesthetic purposes. In the construction industry, they are commonly used for roofing and cladding applications. 5. Metallic Coatings: Metallic coatings such as tin, nickel, and chromium can be applied to steel coils to confer specific properties, such as improved electrical conductivity, increased hardness, or enhanced resistance to wear and tear. 6. Ceramic Coatings: Ceramic coatings are employed to achieve high-temperature resistance and thermal barrier properties. They find application in situations where steel coils are exposed to extreme heat or in industrial processes that require thermal insulation. Each type of coating possesses unique properties and advantages, and the selection of a suitable coating depends on the specific requirements of the application. Manufacturers and engineers carefully consider factors such as cost, durability, corrosion resistance, and aesthetic appeal when deciding on the appropriate coating for steel coils.

- Q: What is the process of slitting steel coils into narrower strips?

- The process of slitting steel coils into narrower strips involves feeding a large steel coil through a slitting machine. The machine uses circular blades or rotary knives to make precise cuts along the length of the coil, creating narrower strips. These strips are then rewound onto separate reels or spools, ready for further processing or shipment.

- Q: I'm writing a story, and trying to find out how hot it needs to be for steel to turn into a gas.

- Steel is to broad. There are many types of steel with different melting/boiling points. Iron* has a boiling point of 5182 °F and a Heat of vaporization of 340 kJ·mol?1. iron is the main ingredient of steel, along with carbon and other various elements.

- Q: How are steel coils inspected for bendability?

- Steel coils are inspected for bendability using a variety of methods to ensure their suitability for various applications. One common inspection method is the 3-point bend test, where the coil is subjected to a bending force at three specific points along its length. This test helps determine the coil's resistance to bending without fracturing or breaking. During the 3-point bend test, the coil is placed on a support system with two fixed points and one movable point. A force is then applied to the movable point, causing the coil to bend. The amount of force required to achieve a specific level of bending is measured and compared against acceptable standards. Another method used for inspecting steel coils is the mandrel bend test. In this test, a mandrel of a specific diameter is inserted into the coil and bent to a specified angle. The coil is then examined for any signs of cracking or deformation. This test helps determine the coil's flexibility and ability to withstand bending without damage. Visual inspection is also an important part of the inspection process. Trained inspectors visually examine the coil for any visible defects such as cracks, deformations, or irregularities. They also check for proper coil dimensions and uniformity throughout. In addition to these methods, non-destructive testing techniques like ultrasonic testing or magnetic particle inspection may be used to detect any internal defects or flaws that may affect the bendability of the coil. Overall, a combination of mechanical testing, visual inspection, and non-destructive testing methods are employed to ensure that steel coils meet the required bendability standards. These inspections help ensure the quality and reliability of the steel coils for various industries where bendability is a critical factor.

- Q: How are steel coils used in the manufacturing of construction reinforcement bars?

- Steel coils are used in the manufacturing of construction reinforcement bars by being processed through a series of steps. The coils are first uncoiled and then straightened before being cut to the desired length. These cut lengths are then shaped and bent into the required reinforcement bar shape using specialized machinery. Finally, the bars are heat-treated and cooled to enhance their strength and durability. Overall, steel coils serve as the primary raw material for the production of construction reinforcement bars, providing the necessary strength and structural integrity to concrete structures.

- Q: what is the refining process doing to raw materials in steel

- The refining process removes impurities. Impurities are anything that is not iron (Fe). Most steels are at least 98% iron, with a fraction of a percent of carbon, a dash of manganese, and traces of sulphur and phosphorus. These are called carbon steels. The non-iron elements are impurities found with the iron in the ore. A certain amount of carbon and manganese is beneficial to the strength of steel, so part of the refining process is designed to control the carbon and manganese content to give desired properties to the steel. Sometimes small amounts of these are added in the process. Besides the common carbon steels, there are many alloys of steel in use today. Alloying is done after the steel is refined to over 98% iron, and while it is a liquid. Various elements are added to the steel in controlled amounts to give it special properties. These include silicon, aluminum, magnesium, vanadium, beryllium, nickel and chromium, and sometimes molybdenum, tungsten and titanium. Alloy steels are still mostly iron, ususally at least 95%, but some stainless steels are only 75% iron because of large amounts chromium and nickel added to the mix.

- Q: in broken steel can you to missions and get things like the dog, you previously didnt do/get in fallout 3?

- Yes, with Broken Steel there is no end to the game. You survive the main quest where you would die in the original game and may go on to explore the wasteland forever.

- Q: Apparently, this has to do something with electrochemical cells.

- Steel wood? I don't think there is such a thing?

- Q: What are the common sizes of steel coils?

- The common sizes of steel coils vary depending on the specific needs and requirements of different industries. However, there are some standard sizes that are commonly used in the steel manufacturing and processing sectors. These include: 1. Slit Coils: Slit coils are typically smaller in size and are commonly available in widths ranging from 0.5 inches to 72 inches. The weight of slit coils varies, but it is usually between 1000 pounds to 50,000 pounds. 2. Master Coils: Master coils are larger in size and are typically used in steel processing facilities to produce various steel products. The width of master coils usually ranges from 36 inches to 96 inches, while the weight may vary from 5,000 pounds to 60,000 pounds. 3. Sheet Coils: Sheet coils are often used in construction, automotive, and appliance manufacturing industries. The standard sizes for sheet coils vary, but they are commonly available in widths of 48 inches, 60 inches, and 72 inches, with lengths ranging from 96 inches to 240 inches. 4. Plate Coils: Plate coils are primarily used in heavy-duty applications such as shipbuilding, bridge construction, and pressure vessel manufacturing. The sizes of plate coils are typically larger, with widths ranging from 36 inches to 96 inches, and lengths varying from 96 inches to 480 inches. It is important to note that these sizes are not fixed and can be customized based on specific customer requirements. Steel manufacturers and suppliers often have the capability to produce coils in various sizes to meet the diverse needs of their clients.

- Q: I've played guitar for years, now I want a steel guitar. As a beginner, to learn and experiment with, which one would be better for me?

- Pedal steel is very difficult. You need to co-ordinate both hands, both feet and both knees to play it effectively. Lap steel is a lot easier. I suppose it depends how much of a challenge you want. A good lap steel guitar is usually cheaper than a good pedal steel too, so that's another consideration to take into account.

Send your message to us

cnbm color coated aluzinc steel coil for constuction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 300000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords