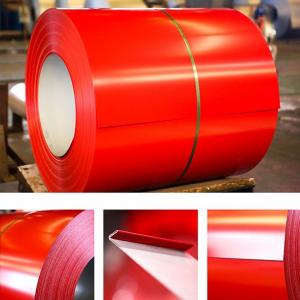

Color Coated Alu-zinc Steel Coil PPGP for building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | SGCC,SGCD1,SGCD2.SGCD3,SGC340, | Thickness: | 0.17-2.0mm |

| Place of Origin: | China (Mainland) | Brand Name: | Model Number: | SGCC,SGCD1,SGCD2.SGCD3,SGC340, | |

| Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | Coated |

| Application: | widely | Special Use: | High-strength Steel Plate | Width: | 600-1250mm |

| Length: | coil |

Packaging & Delivery

| Packaging Detail: | standard sea-worthy packaging or as buyers' requirement. |

| Delivery Detail: | Within 20-30 days after we receive depoist or L/C at sight |

color coated steel coil

Product Description

Company | CNBM |

Product | color coated steel coil |

Port | Shang Hai China |

Thickness | 0.17-2.0mm |

Width | 600-1250mm |

Material Grade | SGCC,SGCH,SGCD1-SGCD3,DX51D |

Technique | cold rolled |

Standard | ASTM,GB ,AISI,JIS,EN |

Test | With Hydraulic Testing, Eddy Current , Infrared Test |

Application | Widely used for roofs, outer walls, ovens, explosive-proof steel, electrically controlled cabinets,galvanized tube/pipe, ceiling channel, building material |

Surface | coated |

Package | standard sea-worthy packaging or as buyers' requirement. |

MOQ | 20 tons |

Payment | L/C,T/T |

Delivery time | According to The Specifications And the Quantities,Time Begin When We confirm the Date of the Earnest or L/C. |

- Q: I went to the store to get metal to make a knife and they had weldable steel and plate steel. Which one would be best/ which steels would be best for what i want to do?

- Weldable steel is a generic term for steel with low carbon content which makes it easy to weld, form, and machine. If you're looking for a knife blade material, you need either a stainless steel or a high carbon steel which is not at all weldable. The more carbon in steel, the better it responds to heat treatment like hardening, tempering, etc. Plus, the high carbon steel will hold an edge better. Hope this helped.

- Q: How are steel coils used in the manufacturing of elevator components?

- Steel coils are used in the manufacturing of elevator components as they provide the raw material for producing various parts such as brackets, frames, and structural supports. These coils are processed through cutting, bending, and shaping techniques to create the necessary components that ensure the safe and efficient operation of elevators.

- Q: Can steel coils be deep-drawn?

- Yes, steel coils can be deep-drawn. Deep-drawing is a metal forming process where a sheet or coil is drawn into a die cavity to create a three-dimensional shape. Steel coils, due to their high strength and ductility, are often used in deep-drawing applications to produce various products such as automotive parts, kitchen appliances, and containers.

- Q: How are steel coils used in the production of construction materials?

- Due to their strength, durability, and versatility, steel coils find widespread usage in the manufacturing of construction materials. Typically made from high-quality steel, these coils are shaped into continuous, cylindrical forms. In the realm of construction material production, steel coils serve different purposes. One primary application involves their use in the creation of steel beams, vital components in constructing buildings, bridges, and other structures. By processing and shaping the steel coils to the desired dimensions, they can easily be formed into beams capable of bearing heavy loads and providing structural support. Another significant utilization of steel coils in construction materials lies in the production of roofing materials. Transforming these coils into corrugated sheets, which are commonly employed as roofing panels, proves highly beneficial. Steel's durability and ability to withstand harsh weather conditions make it an ideal choice for safeguarding buildings against rain, snow, and strong winds. Moreover, these steel coils can be coated with protective layers to enhance their longevity and prevent corrosion. In addition, steel coils play a crucial role in fabricating construction materials such as pipes, tubes, and poles. By shaping the coils according to desired specifications, robust and reliable components for infrastructure projects can be created. Whether for underground pipelines, structural support systems, or utility poles, steel coils provide the necessary strength and durability required for these construction materials. Furthermore, steel coils assume a vital role in the production of construction materials employed in the fabrication of various fixtures and fittings. Through processing and shaping, steel coils can be transformed into door frames, window frames, reinforcement bars, and wire mesh, among other essential elements. This versatility allows for the creation of a wide range of construction materials indispensable for completing buildings and infrastructure projects. In conclusion, the utilization of steel coils in the production of construction materials is driven by their strength, durability, and versatility. Whether in the form of steel beams, roofing materials, pipes, or fixtures, these coils are molded into various shapes and sizes that cater to the specific requirements of construction projects. The incorporation of steel coils guarantees that construction materials possess strength, reliability, and the ability to withstand the demands of the built environment.

- Q: what are the properties that can strengthen the steel to withstand earhquake?

- Well, its not necessary how strong steel is but how buildings are designed that withstands earthquakes. Steel as a property has to elastic qualities and when earthquakes are initiated but moving of the plates, the building has to absorbed the effects of the earth movements while remain standing. This does not necessary mean that the building will be usable afterward but it has to remain standing. Now, how does a building remain standing? All building have within its design a VLLRS (vertical lateral load resisting system). This system is basically designed to resist earthquake loads as well as wind loads. In steel buildings, this system is usual made of OMF (Ordinary moment frames) or braced frames. These frames act to absorb the lateral loads and transmit them into the foundation below. If the structure was concrete, there would still be moment frames made of concrete and steel but you know that concrete has a elasticity that is less than steel. ALthough there elasticity is less, they are stiffer and concrete structure tend to resist more lateral load because of it. In concrete, we can create shear walls which are basically walls that are thick and wide to resist lateral load from earthquake and wind. Masonry has even a lesser strength than steel or concrete and wood even less than above. What makes them usful is how they are used to resist earthquake loads or lateral loads from earthquake and wind. So, to answer your question, its not nessary how strong the steel is but how the material is used to resist earthquake is what is important.

- Q: How are steel coils used in the production of household goods?

- Steel coils are used in the production of household goods as they are a primary material for manufacturing various products. They are commonly used in appliances, such as refrigerators, stoves, and washing machines, as well as in furniture, shelving units, and even construction materials. The steel coils are typically shaped, cut, and formed into specific components or structures required for these household goods, ensuring durability and strength in the final products.

- Q: How are steel coils inspected for defects?

- Steel coils are inspected for defects through visual inspection, non-destructive testing methods such as ultrasonic testing or magnetic particle inspection, and dimensional measurements. These inspections help identify any surface defects, cracks, or irregularities in the steel coils.

- Q: What are the environmental impacts of producing steel coils?

- The production of steel coils has several environmental impacts. The primary concern is the emission of greenhouse gases, especially carbon dioxide, during the manufacturing process. Steel production is energy-intensive and relies heavily on fossil fuels, which contribute to climate change. Additionally, the extraction and processing of raw materials, such as iron ore and coal, can lead to habitat destruction, soil erosion, and water pollution. The steel industry also generates significant amounts of waste, including slag and dust, which can have detrimental effects on ecosystems if not properly managed. Overall, the environmental impacts of producing steel coils necessitate sustainable practices to minimize emissions, conserve resources, and mitigate ecological harm.

- Q: Hi, I have ranch style home. I would like to remove a barring wall, And leave it open it will become a 18' foot 7 inch opening , and I'm interested in installing a steel beam so that i may remove the barring wall that supporting the ceiling and rafters. My house is about 57' feet long 28' feet 7 inch wide and it is 13' feet high from the floor to the top of the roof ridge. I heard there is aluminum beams but I never heard of that, I've only heard of steel beams. I don't want to use wood. I would also like to now how much longer do i need the beam to be the opening would be 18'7 plus the extra that i would need to put on the block wall to hold the beam up, do I make it 2' feet bigger so i can have a foot on each side that would sit on a block wall. or do i need more then that.THanks for your help

- My okorder for help

- Q: What are the different types of steel coil handling devices?

- There are several types of steel coil handling devices, including coil lifters, coil grabs, coil tongs, coil hooks, and coil C-hooks. These devices are designed to safely and efficiently handle steel coils of various sizes and weights, allowing for easy transportation and storage in industrial settings.

Send your message to us

Color Coated Alu-zinc Steel Coil PPGP for building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords