CNBM 304/316/430/201 stainless steel sheet/plate with best price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,the description of the 304/316/430/201 stainless steel sheet/plate with best price

2,Stainless steel maintenance:

(1) Regular cleaning and maintenance

(2) Pay attention to prevent the occurrence of the phenomenon of surface scratches

(3) Use soap, weak detergent or warm water to remove surface dust, dirt

(4) In addition to the surface of the binder with alcohol or an organic solvent (ether, benzene)

(5) Use neutral detergent or ammonia solution in addition to surface oil

(6) With 10% nitric acid or abrasive detergent in addition to the surface of the embroider caused by the dirt.

3, related peoducts show

4,Speciality and advantages:

1. Our company has been dedicated to producing stainless steel seamless pipe since 2003, owning complete producing technology and abundant managing experience.

2. The raw material such as mother tube, round bar we use is from Chinese biggest and well-known steel mill: Walsin Steel and Yongxing Steel.

3. We have advanced NDT equipments for the tests such as Eddy Current test, Ultrasonic test, Hydraulic test and so on.

4. We have ISO 9001 and PED certificate, and the Third Party Inspection Certificates such as TUV, BV, Lloyd’s, SGS, etc, also can be provided according to customers’ requirements,

5. Wooden case package which is strong and suitable for sea transportation is our main method to pack the pipes. And the economical packing method such as packed in bundles is also welcomed by some customers.

6. The tolerance control we use is D4/T4 (+/-0.1mm) on both inside and outside Diameter and Wall Thickness, which is much higher than international standard ASTM, DIN.

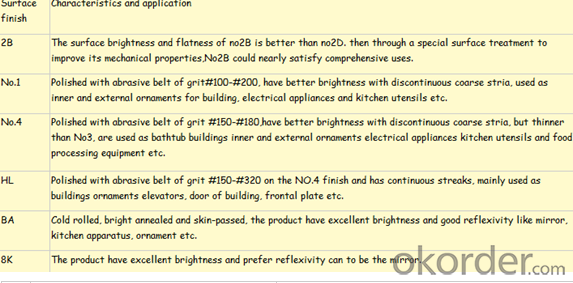

7. The surface condition is one of our main advantages: in order to meet different requirements for surface condition, we have annealing and pickling surface, bright annealing surface, OD polished surface, OD & ID polished surface etc.

5,FAQ

1. Q: What are your advantageous Products?

A: We specialized in 400 series cold rolled stainless steel coils and plates. Our main products are 430, 410S and 409L.

We also supply stainless steel strips and strips in coil as requested.

2. Q: Can you make DDQ ( Deep Drawing Quality)?

A: Yes, we can. Our material can be used for stainless steel pots, stainless steel sinks, stainless steel bowls etc. U can tell us your usage, and we will adjust the mechanical propertise to meet your requirement.

3. Q: What is the application of 400 series stainless steel?

A: 410S stainless steel and 430 stainless steel are widely used for: kitchenware, tableware, cutleries, stainless steel pots, plates & bowls, sinks, gas stove, disinfection cabinet, household appliances, construction decorations etc. 409L stainless steel is usually used for exhaust pipe.

- Q: Do the steel sheets come in different finishes?

- Indeed, steel sheets are available in various finishes. Among the most frequently used finishes for steel sheets are brushed, polished, matte, satin, and textured. These finishes are attained through diverse methods, including grinding, sanding, or applying chemical treatments. The preferred finish is contingent upon the desired visual appeal, functionality, and intended purpose of the steel sheet. Diverse finishes can offer distinct degrees of luster, sleekness, or texture, thereby enabling customization and adaptability across a range of applications, including architectural, automotive, and industrial sectors.

- Q: Are steel sheets suitable for building envelopes or curtain walls?

- Yes, steel sheets are suitable for building envelopes or curtain walls. Steel offers excellent strength and durability, making it a reliable choice for construction projects. It can withstand harsh weather conditions and provide a secure barrier against external elements. Additionally, steel sheets can be easily manipulated to create various architectural designs, allowing for flexibility and creativity in building envelope and curtain wall designs.

- Q: Are steel sheets suitable for laser cutting or engraving?

- Yes, steel sheets are suitable for laser cutting and engraving. The high intensity laser can easily cut through steel sheets, while engraving techniques can be used to create intricate designs or markings on the surface of the steel.

- Q: How is the weight of the steel plate calculated?

- The weight of the steel plate is calculated in this way:Weight = length (unit m) * width (unit m) * thickness (unit mm) *7.85

- Q: Can the steel sheets be easily engraved or etched?

- Yes, steel sheets can be easily engraved or etched using various techniques such as laser engraving or chemical etching.

- Q: What is the average yield strength of steel sheets?

- The average yield strength of steel sheets can vary depending on the specific grade and thickness of the steel being used. However, as a general range, the average yield strength of steel sheets typically falls between 250 and 600 megapascals (MPa). It is important to note that different steel grades, such as mild steel, high-strength low-alloy (HSLA) steel, or stainless steel, will have different average yield strengths. Additionally, the thickness of the steel sheet can also impact its yield strength, with thinner sheets generally having higher yield strengths. Therefore, it is crucial to consult the specifications and standards provided by the manufacturer or industry guidelines to determine the specific average yield strength for a particular steel sheet.

- Q: What are the different surface finishes for pre-painted steel sheets?

- Some of the different surface finishes for pre-painted steel sheets include smooth, textured, matte, glossy, and metallic finishes.

- Q: How long do steel sheets last?

- Steel sheets can last for many years, often surpassing the lifespan of other materials. The longevity of steel sheets depends on various factors such as the quality of the steel, the conditions it is exposed to, and how well it is maintained. In general, high-quality steel sheets that are properly installed and maintained can last for several decades or even longer. However, if steel sheets are exposed to harsh environments, such as extreme temperatures, humidity, or corrosive substances, their lifespan may be reduced. Regular inspections, cleaning, and maintenance can help extend the lifespan of steel sheets and ensure their durability over time.

- Q: Can steel sheets be used for soundproofing purposes?

- Yes, steel sheets can be used for soundproofing purposes. Steel is a dense and rigid material that effectively blocks the transmission of sound waves. When used in soundproofing applications, steel sheets can help reduce the amount of sound that passes through walls, floors, or ceilings. They can be installed as a barrier or added as an additional layer to existing structures to increase their soundproofing capabilities. However, it is important to note that steel sheets alone may not provide complete soundproofing, as sound can still travel through other pathways such as windows or doors. Therefore, a comprehensive soundproofing strategy may involve combining steel sheets with other sound-absorbing materials, such as acoustic foam or insulation, to achieve optimal results.

- Q: Can steel sheets be used for wall cladding?

- Certainly! Wall cladding can indeed be achieved by utilizing steel sheets. Steel, being a highly adaptable and enduring material, finds its utility in diverse applications, one of which is wall cladding. By employing steel sheets, one can obtain exceptional structural reinforcement, resistance against harsh weather conditions, and an aesthetically pleasing look. Steel sheets are frequently employed in commercial and industrial establishments, as well as residential properties, to elevate their visual appeal and safeguard the underlying structure. These sheets can be customized to meet specific design requirements and are available in a wide range of finishes, textures, and colors, making them a favored choice for wall cladding. Furthermore, steel cladding offers numerous advantages, such as fire resistance, ease of maintenance, and long-lasting performance, rendering it a perfect option for wall cladding in various environments.

Send your message to us

CNBM 304/316/430/201 stainless steel sheet/plate with best price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords