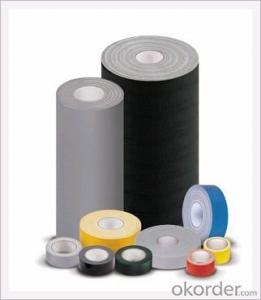

Cloth Binding Tape

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Material: | Use: | Adhesive Side: | |||

| Adhesive: | Adhesive Type: | Feature: | |||

| Design Printing: | Place of Origin: | Brand Name: | |||

| Model Number: | Product name: | Tape thickness: | |||

| Tape width: | Tape Length: | Colour: | |||

| MOQ: | Delivery time: | Loading capability 1*20 FCL: | |||

| Loading capability 1*40 HQ: |

Packaging & Delivery

| Packaging Detail: | Cloth binding tape. Inside packing:opp shrink film. Outside packing:paper carton. |

| Delivery Detail: | 15 days |

Specifications

Cloth binding tape.

Materials:Polythylene,fabric reinforcement

T:230-280mic

W:12-72mm

L:5-50m

- Q: What is the tensile strength of silicone rubber?

- The main characteristics of silicone rubber:High and low temperature performance, the range is -100-300 degrees centigrade.Ozone aging, heat resistance, oxygen aging and weather aging are good.The electric insulation performance is good, can do high-grade insulation products.It has excellent biomedical properties, non-toxic and tasteless.Good sealing performance.

- Q: What problems need to pay attention to when inflating the pipe?

- Rubber pipeline plugging bag should keep the inner pressure of the gasbag is uniform when inflated, inflated slowly rising inflation, observe the pressure gauge without change, such as pressure gauge shows rapid rise in inflation is too fast, the inflation rate should slow down, stop valve will tighten slightly, reduce the inlet velocity, or the speed is too fast, faster than pressure is likely to break into the rubber balloon. - Zhang

- Q: In addition to the smell of rubber?

- Soil recruit: 300 grams of black tea, hot tea, two washbasin water, into the living room, and window ventilation, 48 hours, indoor formaldehyde content will fall by more than 90%, the pungent odor is basically eliminated.

- Q: What are the forming methods of rubber products?

- In rubber products, the main molding technologies are molding, forming, transfer, forming, wrapping, molding and injection molding.

- Q: What is the size of the scorch time of the rubber?

- Rubber is a mixture of organic and inorganic compounds. The main component is organic matter, and the scorch time can reflect the weather resistance and fire resistance of the product.

- Q: Can the rubber surface be painted with paint?

- Rubber surface of the original jet printing pattern, etc., how to remove clean, and does not affect the appearance and rubber layer: the way is solvent oil!

- Q: How do you remove the black dirt on the rubber?

- You should be rubber silicone, most of all is blackTry rubbing it with diluted alcohol.

- Q: Rubber products are not allowed to touch oil products, but why can rubber gloves be contacted daily? What's the point?

- Most rubber materials are not resistant to oil, some rubber materials are resistant to oil, such as nitrile rubber, etc., the family commonly used detergent on rubber gloves did not affect.

- Q: How to make rubber products keep brightness for a long time?

- Rubber products should be painted with rubber bright oil, in case the rubber formula is designed, the product is shiny and the oil is not sprayed.

- Q: How to solve the spray of rubber products?

- 1, dry finished products should be packaged sealed, placed in a cool and dry place inventory, avoid sunlightDirect irradiation,2. For the rubber products with the condition of spitting and spitting, the air and temperature at the storage place shall be controlled after the processingDegree and humidity conditions,3, as soon as possible out of storage, not long storage, reduce the aging opportunities of rubber products.

Send your message to us

Cloth Binding Tape

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords