Book Binding Tape

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Material: | Use: | Adhesive Side: | |||

| Adhesive Type: | Feature: | Design Printing: | |||

| Place of Origin: | Brand Name: | Certification: | |||

| color: | Adhesive: | mesh: | |||

| thickness: | raw material: | paper core diamater: | |||

| sample provide: | OEM: |

Packaging & Delivery

| Packaging Detail: | single roll per shrink.. six rolls per shrink.. as customer request.. |

| Delivery Detail: | 25days after we receive the deposits. |

Specifications

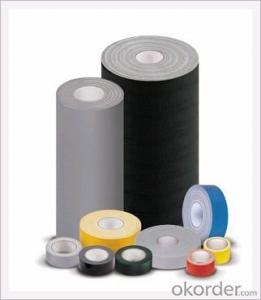

book binding tape:

1.take the cloth as the material...

2.waterproof and easy to tear...

3.high quality...

4.good adhesive...

Feature of book binding tape :

Has the balanced peeling strength, initially the stick force, stretching resistance, waterproofing and easy to rip one kind of high viscosity adhesive tape.

Usage:used for general repair, general sealing , jointing, weather proofing and color coding.

Welcome to send inquiries to us.

mesh: 30/35/45/50/70mesh

width; 24mm/36mm/48mm/50mm/72mm/76mm

color: red, black, grey, brown, yellow, green, white, blue

paper core diamater: 1.5''/3''

package: single roll per shrink,

six rolls per shrink,

as customer request

qty: 36roll per ctn

48roll per ctn

72roll per ctn

thickness: 180mic-250mic

- Q: What are the differences in the properties of neoprene models?

- Good physical and mechanical properties, oil resistance, heat resistance, fire resistance, sunlight resistance, ozone resistance, acid and alkali resistance, chemical reagents. The disadvantage is cold resistance and poor storage stability. With high tensile strength, elongation and reversible crystallinity, good adhesion. Aging resistance, heat resistance. Excellent oil resistance and chemical resistance. Weatherability and ozone resistance are second only to that of ethylene propylene rubber and butyl rubber. The heat resistance and the nitrile rubber, the decomposition temperature of 230~260 DEG C, short-term resistance at 80~100 DEG 120~150 DEG C, can be used for a long time, with a certain flame retardancy. Oil resistance second only to nbr. Good resistance to inorganic acids and alkalis. Cold resistance is slightly worse, electrical insulation is poor. Rubber poor storage stability, will have a "sulfur" phenomenon, Mooney viscosity increased, hard rubber. Foreign brands are: AD 1, 30 (USA), A-90 (Japan), 320 (Germany), and MA40S (France).

- Q: What does the rubber tire do to people?

- Rubber is divided into natural rubber and synthetic rubber according to its raw material. According to the form is divided into block rubber, latex, liquid rubber and rubber powder. Latex as a rubber colloidal water dispersion; liquid rubber as an oligomer of rubber, not before the vulcanization is generally viscous liquid; powder rubber is the latex processing into powder, in order to benefit ingredients and processing. Thermoplastic rubber, developed in 1960s, does not require chemical vulcanization and is shaped by thermoplastic processing. Rubber according to the use of divided into general and special type of two categories. It is not easy to insulator, conductive, but if water or different temperature, are likely to become a conductor. Conduction is the conduction of electrons in a substance, molecule, or ion.

- Q: When rubber products are hardened, what methods soften?

- Either hardening or vulcanization. Vulcanized rubber becomes elastic rubber. This is an irreversible process. The elastomer can be changed into a plastic regenerated rubber by the desulfurization process.

- Q: What are the application fields of waste tire rubber powder?

- Waste tire rubber powder from 900 to 1200 waste tire as the main raw material, the production method of low temperature refrigeration by air turbine (0.425mm) 40 mesh to 200 mesh (0.0750mm) crumb rubber with high fineness, tensile strength, the proportion of small, good liquidity.

- Q: Process for producing rubber products

- There are many kinds of rubber products, but the production process is basically the same. The basic process of rubber products in general solid rubber - rubber as raw materials including: plastication, mixing, calendering, extrusion, molding, curing 6 basic processes. Of course, raw materials preparation, finishing, inspection, packaging and other basic processes are indispensable. The processing of rubber mainly deals with the contradictory process of plasticity and elasticity. Through a variety of techniques, the elastic rubber plastic rubber has become the addition of various additives made of semi-finished products, and then through the vulcanization has semi-finished plastic and rubber products into high elasticity and good mechanical performance.

- Q: How does the rubber part of the watch become yellow?

- Rubber: the word "rubber" comes from the Indian language "cau-uchu", meaning "weeping tree"". Natural rubber is flowing out from the Hevea latex when tapping after solidification and drying process. The finished product is material with elasticity, insulation, waterproof and air.

- Q: What is the relationship between the hardness and tensile strength of rubber pad?

- Tensile strength is the ultimate ability to characterize a product against tensile failure.

- Q: What about the smell of smoked rubber products?

- The curing agent and accelerator taste, rubber itself is tasteless, sulfur curing agent debris less is better, if no sulfur, with peroxide. Oil will also produce a flavor, rubber Odor Remover can be removed, in fact, that is, some spices, oh!Now there is a special rubber deodorant in the market, you may as well try.Can buy some activated carbon in the box, the cost is not high, but also long lasting odor.

- Q: How can I get rid of the rubber?

- You smell the smell from the vulcanized rubber residues, not much of the flavor is generally placed in a cool ventilated place, you can, and if the smell is large, you can use rubber deodorant, supermarkets generally sell

- Q: What kind of rubber is suitable for waterproof aprons?

- One to do waterproof rubber ring, choose ethylene propylene rubber! The main sealing ring of fire ditch pipe is mainly made of ethylene propylene rubber!! Physical and chemical properties have corresponding national standards!

Send your message to us

Book Binding Tape

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords