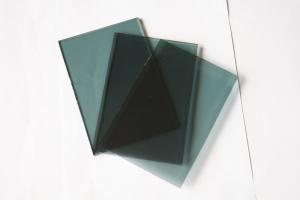

Clear Sheet Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 10000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Sheet Glass is a kind of ultra thin glass, whose thickness is less than 3mm.

Features of Clear Sheet Glass:

1. good planeness

2. little tolerance on thickness

3. excellent quality

Specifications of Clear Sheet Glass:

Thickness: 2.7mm

Size:

500*700mm; 600*900mm

610*914mm; 1220*914mm

1830*1220mm; 1830*2440mm

customized size

Applications of Clear Sheet Glass:

Sheet Glass is mainly used in picture frames, mirrors, windows, building, arts and crafts, instruments, etc.

- Q: What's the name of the transparent plastic board in the market?

- Acrylic is a transliteration word, English is ACRYLIC. It is a chemical material. Chemistry called "PMMA" is a polyacrylate, commonly known as "after the special treatment of plexiglass", in the application industry, acrylic raw materials in general in the form of particles, plates, pipes and other forms.

- Q: Can the toughened glass be cracked by the sun?

- Tempered glass (Tempered, glass/Reinforced, glass) belongs to safety glass. Toughened glass is a kind of prestressed glass, in order to improve the strength of the glass, the methods commonly used in chemistry or physics, formed on the surface of glass glass under compressive stress, first offset surface stress force, so as to improve the bearing capacity of reinforced glass, its wind, cold, impact etc.

- Q: Why is toughened glass broken?

- This is because of containing nickel sulfide crystal glass raw material, manufacturing technology in the world is any existing can not be completely avoided, only reduce the exploding probability through control of the purity of raw materials and processing technology to a.It blew the concept of rate, the national standard of our country only glass project on the wall, I do not know whether the other foreign industry to use the toughened glass also has detailed provisions.

- Q: Raw material, processing method and ratio of glass fiber reinforced plastic

- Raw material:Glass fiber reinforced plastics (FRP), also known as GFRP, that is, fiber reinforced plastics, generally refers to the use of glass fiber reinforced unsaturated polyester, epoxy resin and phenolic resin matrix. Reinforced plastics made from glass fiber or its products are referred to as glass fiber reinforced plastics or glass fiber reinforced plastics.

- Q: What are the raw materials made of glass and plastics?

- Polyethylene (Polyethylene, PE), referred to as PE. is ethylene organic polymer compound. Polyethylene is the best material in contact with food. Non-toxic, tasteless and odorless, conform to the hygiene standards of food packaging. Polyethylene film, transparent, with moisture, oxygen, anti acid and alkali resistance, air tightness in general, excellent heat sealing properties. Known as "plastic flowers" reputation. Plastic packaging and printing volume is the largest and most important materials.PVC-- PVC

- Q: What are the raw materials for making glass?

- Sandstone fused glass has a bright luster, and has a good transparency, acid resistance and mechanical strength.

- Q: Medium temperature glass flake clay products

- Due to the relative stretching coefficient of the steel, cement and other material and substrate, so in the case of heat shock resin layer easily cracking and shedding, and glass flake can provide a heat stable layer, which can prevent the substrate cleavage and shedding.

- Q: What kind of material is the glass made of?

- The chemical composition of glass is Na2SiO3, CaSiO3, SiO2 or Na2O - CaO - 6SiO2, is the main component of silicate, is an amorphous solid irregular structure. Widely used in buildings for wind and light transmission; of mixtures. There is also colored glass mixed with certain metal oxides or salts, and tempered glass made by physical or chemical methods. Sometimes some transparent plastic (such as polymethyl methacrylate) is also called organic glass.

- Q: What is the raw material of glass?

- How is glass produced? Glass production process includes batching, melting, forming, annealing and other processes. The following are described below:1. ingredients, according to the design of the material sheet, weighing all kinds of raw materials, mixing in a mixing machine evenly. The main raw materials of glass are: quartz sand, limestone, feldspar, soda ash, boric acid and so on.2., melting, the raw materials will be prepared by high temperature heating, forming a homogeneous bubble free liquid glass. This is a complex process of physics and chemistry. The melting of glass is carried out in a furnace. There are two main types of Furnaces: one is a crucible kiln, the other is glass in the crucible, and the other is heated outside the crucible. The small crucible kiln has only one crucible, and the larger one can be more than 20 crucibles. The crucible kiln is made by gap type, and now only optical glass and color glass are produced by crucible kiln. The other is the tank furnace. The frit is molten in the bath, and the flame is heated on the upper part of the glass. The glass melting temperature mostly in the 1300~1600 C Eve joy. Most of them are heated by flame and a few are heated by electric current. They are called electric furnaces. Now, the pool kiln is continuous production, small pool kiln can be a few meters, big can be more than 400 meters, 2.

- Q: FRP process piping manufacturing process?

- Glass tube wall structure from inside to outside are: glass fiber reinforced plastic lining layer, glass fiber reinforced plastic sub lining layer, glass fiber reinforced plastic winding layer, glass fiber reinforced plastic external protection layer.

1. Manufacturer Overview

| Location | Shenzhen, China |

| Year Established | 1993 |

| Annual Output Value | US$ 10 Million - US$ 50 Million |

| Main Markets | North America; Europe; Australia; Japan; South East Asia; Middle East; Hong Kong; Macao |

| Company Certifications | ISO 9001:2000;ISO14001:2004;OHSAS 18001 system;3C safety Certificate;SGCC (USA);CE (EU);UL (USA) |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shenzhen |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 50,000-100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | |

Send your message to us

Clear Sheet Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 10000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords