Clear Packaging Tape with PVC Film and Natural Rubber Wire Harness Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

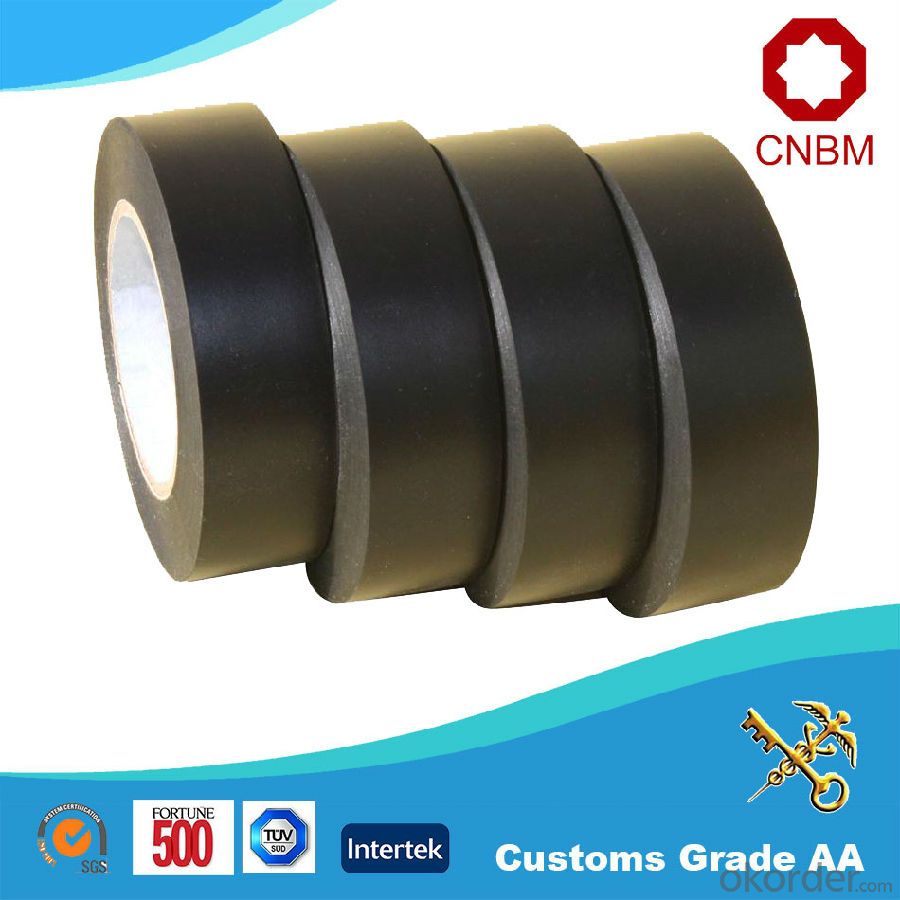

Wire Harness Tape with PVC Film and Natural Rubber

1. Structure of Wire Harness Tape Description

Wire Harness Tape is of PVC film as the carrier, coating with natural rubber. Wire Harness Tape: widely used as permanent wrapping on cables and wiring harnesses for automobile.

2. Main Features of the Wire Harness Tape

Burning-resistance

Non-corrosive adhesive

Self extinguishing

Water resistant and moisture resistant

Safety and environmental friendly

Resistant to cold temperature

3. Wire Harness Tape Images

4. Wire Harness Tape Specification

Item No. | Thickness (micron) | Adhesion to steel (N/cm) | Tensile Strength (N/cm) | Elogation (%) | Teperature Resistance (DC) | Flame Resistance (S) |

PW-11 | 110 | 1.2 | 15 | 150 | 80 | <2< span=""> |

PW-12 | 120 | 1.2 | 16 | 150 | 80 | <2< span=""> |

PW-13 | 120 | 1.2 | 20 | 180 | 80 | <2< span=""> |

PW-15 | 120 | 1.2 | 25 | 200 | 80 | <2< span=""> |

5. FAQ

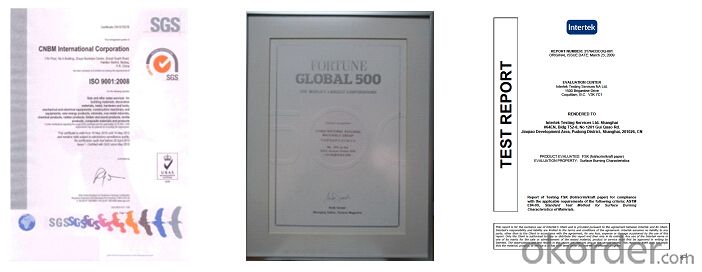

Q1. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

Q2. How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

Q3. Packing and Delivery

Packaging Details: 120 brolls per carton(39*27*30) according to different size

Delivery Detail: 7 to30 days according to different quantity

- Q: Can packaging tape be used for sealing packages with high-value contents?

- Indeed, packaging tape proves useful in sealing packages that contain valuable items. Designed with the specific purpose of ensuring the secure closure of packages, it offers protection against tampering, moisture, and transit-related harm. Possessing strength and durability, packaging tape usually boasts a resilient adhesive backing that guarantees a lasting seal. By employing packaging tape correctly, one can effectively safeguard packages that hold valuable contents, thereby guaranteeing their safe arrival. However, it is crucial to bear in mind supplementary security precautions, such as utilizing tamper-evident tape or incorporating additional layers of protection, depending on the worth and fragility of the items contained within.

- Q: Is packaging tape safe to use on plastic picture frames?

- Yes, packaging tape is generally safe to use on plastic picture frames. It provides a secure and temporary hold without causing damage to the frame's surface. However, it is important to remove the tape carefully to avoid peeling off any paint or finish.

- Q: Can packaging tape be used for sealing poly mailers?

- Yes, packaging tape can be used for sealing poly mailers. Packaging tape is commonly used to seal a variety of packaging materials, including poly mailers. It provides a strong and secure seal that prevents the contents from falling out or being tampered with during transit. However, it is important to ensure that the tape is applied properly and securely to ensure the integrity of the seal. Additionally, it is recommended to use a high-quality packaging tape that is designed for secure sealing to ensure the best results.

- Q: How does the temperature affect packaging tape's adhesive properties?

- The temperature can have a significant impact on the adhesive properties of packaging tape. Generally, the adhesive used in packaging tapes is designed to perform optimally within a specific temperature range. When the temperature is too low, the adhesive may become stiff and lose its ability to bond effectively. This can result in a weakened adhesive bond, leading to tape failure and potential packaging issues. Additionally, low temperatures can cause the adhesive to become less tacky, reducing its ability to adhere to different surfaces. On the other hand, high temperatures can soften the adhesive, making it more susceptible to deformation and losing its cohesive strength. This can result in the tape becoming gooey or even melting, which can compromise its ability to hold packages securely. High temperatures can also cause the adhesive to become more tacky, making it difficult to handle and potentially leaving residue behind when the tape is removed. In summary, extreme temperatures can negatively impact packaging tape's adhesive properties. It is crucial to consider the recommended temperature range for the specific tape being used to ensure optimal performance and a secure packaging solution.

- Q: How does packaging tape differ from masking tape?

- Packaging tape and masking tape are distinct types of tapes serving different purposes and possessing unique traits. Specifically intended for sealing and securing packages or boxes, packaging tape finds common use in the shipping and packaging industries. It is typically constructed from robust and long-lasting materials like polypropylene or PVC, ensuring exceptional adhesion and resistance against tearing or splitting. Its notable high tensile strength guarantees the package remains securely sealed during transit or storage. Moreover, packaging tape generally boasts a potent adhesive that adheres well to various surfaces, including cardboard, plastics, and metals. It is available in different widths and lengths to accommodate diverse packaging requirements. In contrast, masking tape primarily finds application in painting and DIY projects. Composed of a thinner and less resilient material, such as crepe paper, it possesses a less aggressive adhesive in comparison to packaging tape. The primary objective of masking tape is to establish clean, straight lines and safeguard surfaces from paint or other liquids during painting tasks. Masking tape can be effortlessly applied and removed without leaving any residue or causing damage to the surface. Furthermore, it is recognized for its ability to conform to uneven surfaces, enabling precise masking and detailing work. To summarize, packaging tape is designed for secure sealing and packaging of boxes and packages, whereas masking tape is primarily utilized for painting and surface protection. Packaging tape is stronger, more durable, and possesses a more potent adhesive, whereas masking tape is thinner, more flexible, and can be effortlessly removed without leaving any residue.

- Q: Can packaging tape be used for securing shipments during transit?

- Yes, packaging tape is commonly used for securing shipments during transit. It provides a strong and reliable seal that helps keep packages intact, preventing them from opening or getting damaged during transportation.

- Q: What are the benefits of using transparent packaging tape?

- The benefits of using transparent packaging tape include clear visibility of the contents of the package, easy identification of any tampering or damage, professional appearance, and the tape's durability and strength for securing packages effectively.

- Q: What are the different types of packaging tape available?

- There are several different types of packaging tape available, including transparent tape, brown or tan tape, reinforced tape, water-activated tape, and duct tape. Each type of tape has its own unique properties and is designed for specific packaging needs and applications.

- Q: Is packaging tape waterproof?

- Yes, packaging tape is typically waterproof. It is designed to be resistant to moisture and can provide a strong seal, preventing water from seeping into the package. However, it is important to note that the level of waterproofing may vary depending on the quality and type of packaging tape used. Some tapes may provide a more secure seal than others, so it is always recommended to choose a tape specifically designed for packaging and sealing purposes.

- Q: Which kind of sealing tape is solvent resistant?

- Is the refrigerator and freezer production plant main raw materials, but also insulation materials, Distribution Department will purchase raw materials. This product is widely used in refrigerators, air conditioning, automotive, petrochemical, bridges, hotels, electronics and other industries.

Send your message to us

Clear Packaging Tape with PVC Film and Natural Rubber Wire Harness Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords