Black Vinyl Packaging Tape with Strong Adhesion PVC Wire Harness Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Wire Harness Tape PVC Strong Adhension Cheap

1. Structure of Wire Harness Tape Description

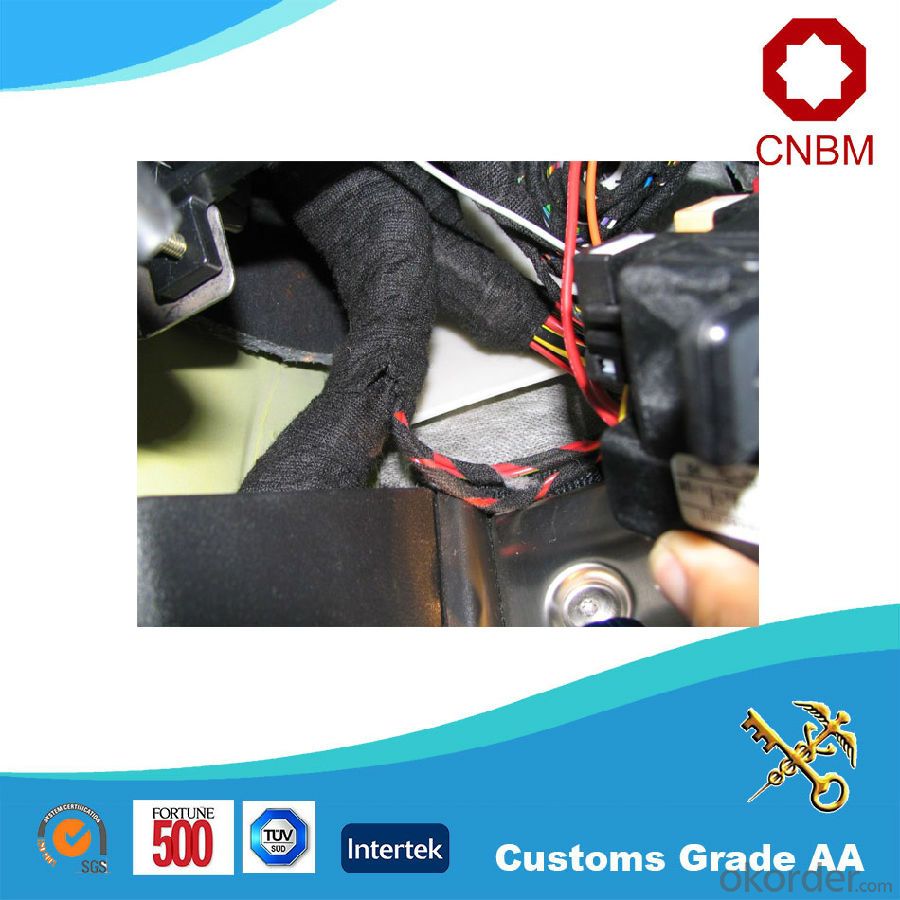

Wire Harness Tape is of PVC film as the carrier, coating with natural rubber. Wire Harness Tape: widely used as permanent wrapping on cables and wiring harnesses for automobile.

2. Main Features of the Wire Harness Tape

High abrasion resistance

Moisture resistant

High adhesive force

Burning-resistance

High tear resistance and stability

Safety and environmental friendly

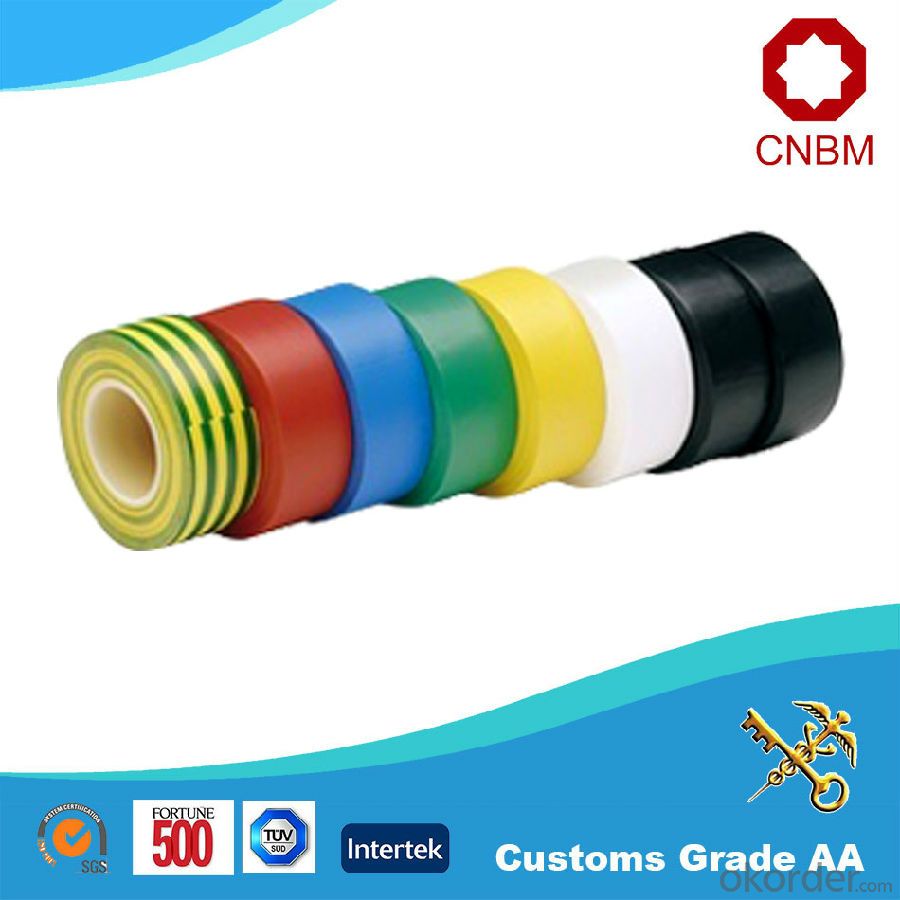

3. Wire Harness Tape Images

4. Wire Harness Tape Specification

Item No. | Thickness (micron) | Adhesion to steel (N/cm) | Tensile Strength (N/cm) | Elogation (%) | Teperature Resistance (DC) | Flame Resistance (S) |

PW-11 | 110 | 1.2 | 15 | 150 | 80 | <2< span=""> |

PW-12 | 120 | 1.2 | 16 | 150 | 80 | <2< span=""> |

PW-13 | 120 | 1.2 | 20 | 180 | 80 | <2< span=""> |

PW-15 | 120 | 1.2 | 25 | 200 | 80 | <2< span=""> |

5. FAQ

Q1. Why choose us?

World Top 500 Enterprise

Quality guarantee with third party certification

OEM service, supported by strong R&D team

One-step service: transportation, capital etc.

A short lead time

Q2. What is the working environment?

Working temperature: from -18°C to +80°C. It is specially conceived for professional electrical insulating applications where environmental safety is concerned.

Q3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Can packaging tape be used for sealing plastic pet carriers?

- Yes, packaging tape can be used for sealing plastic pet carriers. Packaging tape is designed to securely seal boxes and packages, and it provides a strong adhesive bond. When applied properly, it can effectively seal the openings of plastic pet carriers, ensuring that your pet is safely contained inside. However, it is important to ensure that the tape is applied evenly and securely to prevent any gaps or openings that your pet may be able to escape from. Additionally, it is recommended to check the tape periodically to make sure it remains intact and reapply if necessary.

- Q: Can packaging tape be used for sealing plastic toolboxes?

- Indeed, plastic toolboxes can be effectively sealed using packaging tape. Specifically crafted to securely seal boxes and packages, packaging tape exhibits versatility by being suitable for various materials, including plastic. It delivers a robust and long-lasting seal capable of enduring regular handling and transportation. Nevertheless, for extended storage or heavy-duty purposes, it is advisable to opt for a more robust and specialized tape, like duct tape or strapping tape, as they provide enhanced durability and adhesion.

- Q: Does packaging tape come in different thicknesses?

- Indeed, various thicknesses can be found when it comes to packaging tape. One can find packaging tape in a range of thicknesses, which caters to diverse needs and demands. Heavier-duty tasks that necessitate extra durability and resilience usually call for thicker tapes. Conversely, thinner tapes are commonly utilized for lighter parcels or regular daily applications. The decision regarding the thickness depends on factors such as the weight and dimensions of the package in question, as well as the desired level of fortification.

- Q: What are the different types of packaging tape?

- There are several types of packaging tape available, including clear tape, brown tape, duct tape, masking tape, and double-sided tape. Each type has its own specific use and characteristics, such as transparency, strength, adhesive properties, and thickness.

- Q: How strong is packaging tape?

- Packaging tape is designed to be strong and provide secure and reliable sealing for packages. It has a high tensile strength and adhesive properties that make it capable of withstanding various pressures, ensuring the integrity of packages during transportation and storage.

- Q: Can packaging tape be used for sealing plastic storage baskets?

- Yes, packaging tape can be used for sealing plastic storage baskets. Packaging tape is designed to be strong and adhesive, making it suitable for securing and sealing various types of materials, including plastic. By using packaging tape, you can effectively seal the openings or seams of plastic storage baskets, keeping the contents secure and protected. However, it is important to note that the longevity and effectiveness of the seal may depend on the quality and durability of the specific packaging tape used. Additionally, it is recommended to clean and dry the surface of the plastic storage baskets before applying the tape to ensure proper adhesion.

- Q: Can packaging tape be used for sealing packages with medical or pharmaceutical products?

- Indeed, packaging tape can certainly serve as a means to seal packages containing medical or pharmaceutical items. Nonetheless, it is crucial to take into account the precise requirements and regulations pertaining to packaging within the medical and pharmaceutical sectors. Such industries often uphold rigorous standards concerning packaging materials, aiming to guarantee the safety, soundness, and adherence to regulatory guidelines of the products. Consequently, it is advisable to opt for packaging tape specifically formulated and authorized for use in medical or pharmaceutical contexts. These tapes are typically composed of moisture-resistant and tamper-proof materials, ensuring a robust seal to safeguard the package's contents. By utilizing approved packaging tape, the quality and integrity of medical or pharmaceutical products can be preserved throughout storage and transportation.

- Q: What are the considerations for using packaging tape on plastic packaging materials?

- When using packaging tape on plastic packaging materials, there are several considerations to keep in mind. First and foremost, the adhesive on the tape should be compatible with the type of plastic being used, as certain plastics may not adhere well to certain types of adhesives. Additionally, the tape should be strong enough to securely hold the packaging together, while also being flexible enough to accommodate any movement or shifting of the materials. It is also important to consider the environmental impact of the packaging tape, opting for eco-friendly options whenever possible. Finally, any printing or labeling on the packaging tape should be legible and easily visible to ensure proper identification and handling of the packaged materials.

- Q: Which kind of sealing tape is solvent resistant?

- High temperature tapes are solvent resistant. Aluminum foil tape adopts high quality pressure-sensitive adhesive, good adhesion, strong adhesion, anti-aging and other effects

- Q: Can packaging tape be used for sealing storage containers?

- Yes, packaging tape can be used for sealing storage containers.

Send your message to us

Black Vinyl Packaging Tape with Strong Adhesion PVC Wire Harness Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords